High quality textured composite resin composition and galvanized steel sheet coated with composite resin composition

A technology of composite resin and galvanized steel sheet, applied in the direction of superimposed layer plating, coating, anti-corrosion coating, etc., can solve the problems of low productivity and high price, and achieve the effect of improving stamping workability and chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12 and comparative example 1~11

[0148] As shown in Table 1 below, a urethane-modified polyester resin, a curing agent, an acid catalyst, and an amine catalyst were mixed and put into a solvent to prepare 100 parts by weight of a transparent resin composition. The balance in the transparent resin composition is solvent.

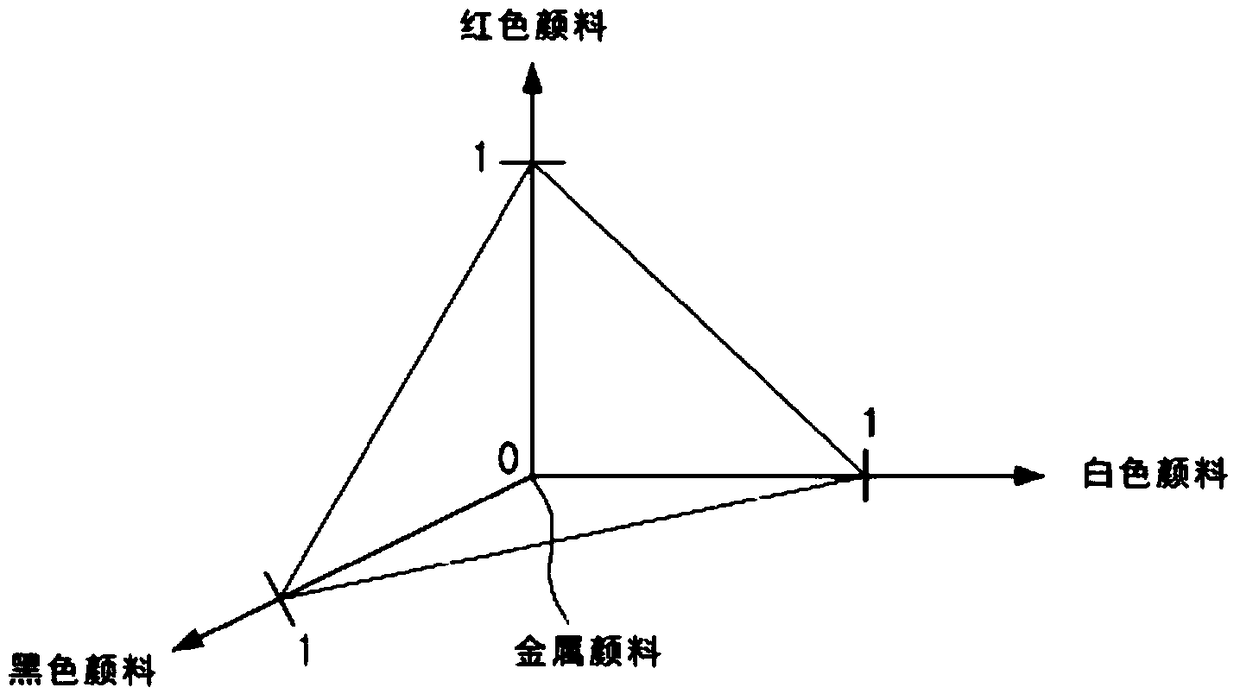

[0149] Next, with the contents shown in Examples 1-12 and Comparative Examples 1-11 in the following Table 1, the urethane-modified polyester resin, curing agent, acid catalyst and amine catalyst, and further added inorganic Pigments and metal pigments are mixed, and then they are put into a solvent and dispersed by a high-speed sand mill disperser. A colored composite resin composition was thus prepared.

[0150] A cross-linked resin (manufactured by KCC Co., Ltd., Tg=10) and a linear resin (manufactured by KCC Co., Ltd., Tg=60) with a weight average molecular weight of 20000 were mixed at a weight ratio of 2:1 as The urethane modified polyester resin is used.

[0151] The curing agent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap