Optical adhesive composition and optical adhesive film comprising adhesive layer containing thermally cured product of optical adhesive composition

一种粘合剂层、粘合剂的技术,应用在薄膜/薄片状的粘合剂、粘合剂类型、羧基橡胶粘合剂等方向,能够解决最终产品应用限制、难以形成固化结构或交联结构、难化学交联等问题,达到优异粘附特性和长期可靠性、优异耐水蒸气透过性和耐化学性、优异长期耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0154] Hereinafter, specific examples of the present invention will be presented. However, the embodiments described below are provided only to specifically illustrate or explain the present invention, and the present invention is not limited thereto.

preparation example 1

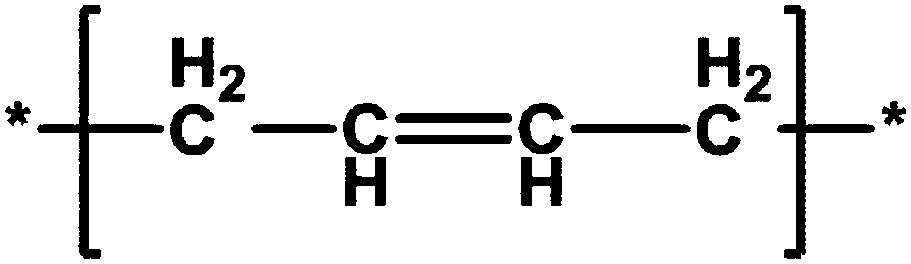

[0157] Step 1: In a 2L reactor (where nitrogen is refluxed and a cooling device is installed so as to adjust the temperature easily), 14% by weight of butadiene rubber (cis content is 97 mol%, BR1208, LG Chem) was dissolved in toluene for 6 hours, then the temperature was lowered to 35°C. Next, 10 parts by weight of a peroxide (mCPBA: m-chloroperoxybenzoic acid) was introduced into 100 parts by weight of butadiene rubber, and the resulting mixture was stirred at 35° C. for 4 hours. Next, 10 parts by weight of an aqueous hydrochloric acid solution having a concentration of 1N was put into 100 parts by weight of the rubber, and the resulting mixture was stirred at 35°C for 1 hour, then the temperature was raised to 90°C, and the mixture was stirred for 1 hour.

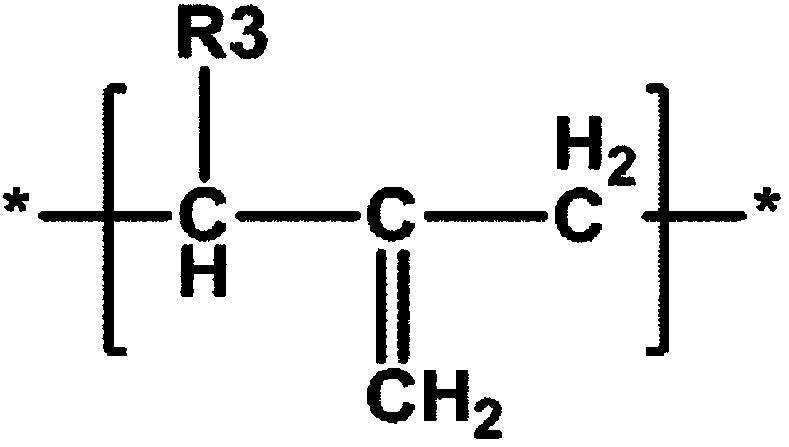

[0158] Step 2: Next, 3 parts by weight of acryloyloxyethyl isocyanate and 200 ppm of dibutyltin dilaurate (DBTDL) were put into 100 parts by weight of rubber, and the resulting mixture was kept at 80° C. for 3 hours.

...

preparation example 2

[0161] Step 1: The process was carried out under the same conditions and compositions as those in Preparation Example 1, except that 15 parts by weight of the peroxide (mCPBA: m-chloroperoxybenzoic acid) in Preparation Example 1 was introduced thereinto.

[0162] Step 2: Same as Step 2 in Preparation Example 1

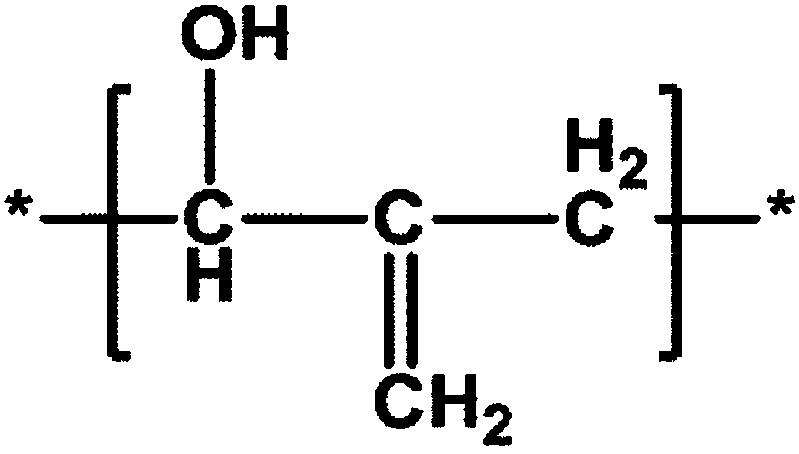

[0163] Through these steps, a polybutadiene rubber having a structure of Chemical Formula 3, having a hydroxyl value of 5.79 mgKOH / g and containing 3% by weight of acrylate groups was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com