Special powder concentrator for dinas, of coal milling system

A powder separator, sand and gravel technology, which is used in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of large powder screening errors, poor screening results, and poor drying effects. , to achieve the effect of fine screening, good screening results and convenient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

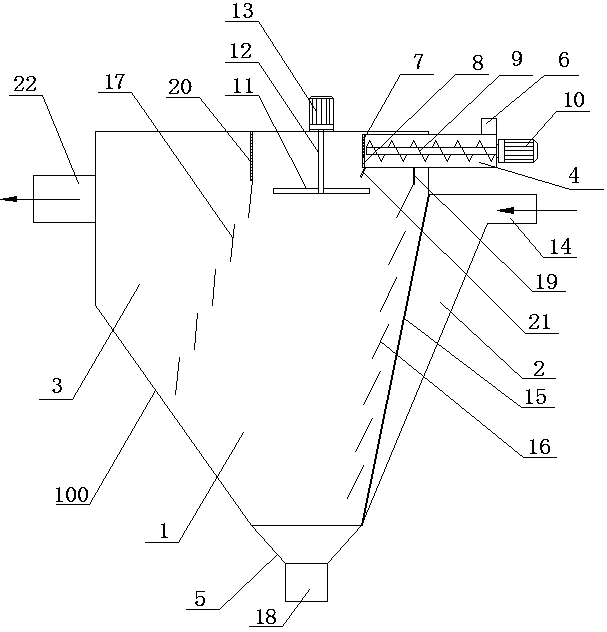

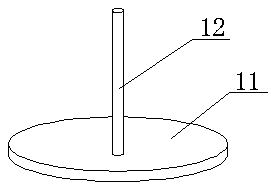

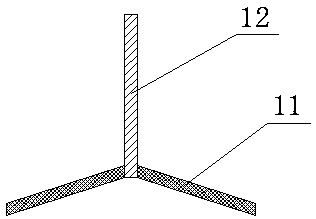

[0018] Such as figure 1 , figure 2 As shown, a special classifier for sand and gravel in the coal mill system, the horizontal arrow in the figure indicates the wind direction. The cyclone of the present invention comprises a winnowing body 100, and the winnowing body comprises a winnowing chamber 1, an air inlet chamber 2, an air outlet chamber 3, a feed chamber 4, and a discharge chamber 5, and the upper part of the winnowing chamber wall is provided with a ventilation hole, the chamber wall of the feed chamber passes through the through hole and is fixedly connected to the hole wall of the through hole; the upper side of the feed chamber away from the winnowing chamber is provided with a feed inlet 6, and the feed chamber is located at the winnowing One side of the chamber is provided with a discharge plate 7, and the discharge plate is provided with a discharge port 8; a screw conveyor 9 is provided in the feed chamber, and the screw conveyor is connected to a conveying m...

Embodiment 2

[0023] In this embodiment, the rotating plate is obliquely connected to the rotating shaft, and the inclination angle between the rotating plate and the rotating shaft is 30-45°. The tilting setting of the rotating wrench makes it easier for materials to fall.

[0024] The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com