A screening machine for sampling and analyzing urban spoil

A soil sampling and screening machine technology, which is applied in dryers, solid separation, and separation of solids from solids by air flow, can solve the problems of unsatisfactory drying degree and inconvenient discharge of large particle materials, and achieve drying Good effect, prolonged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

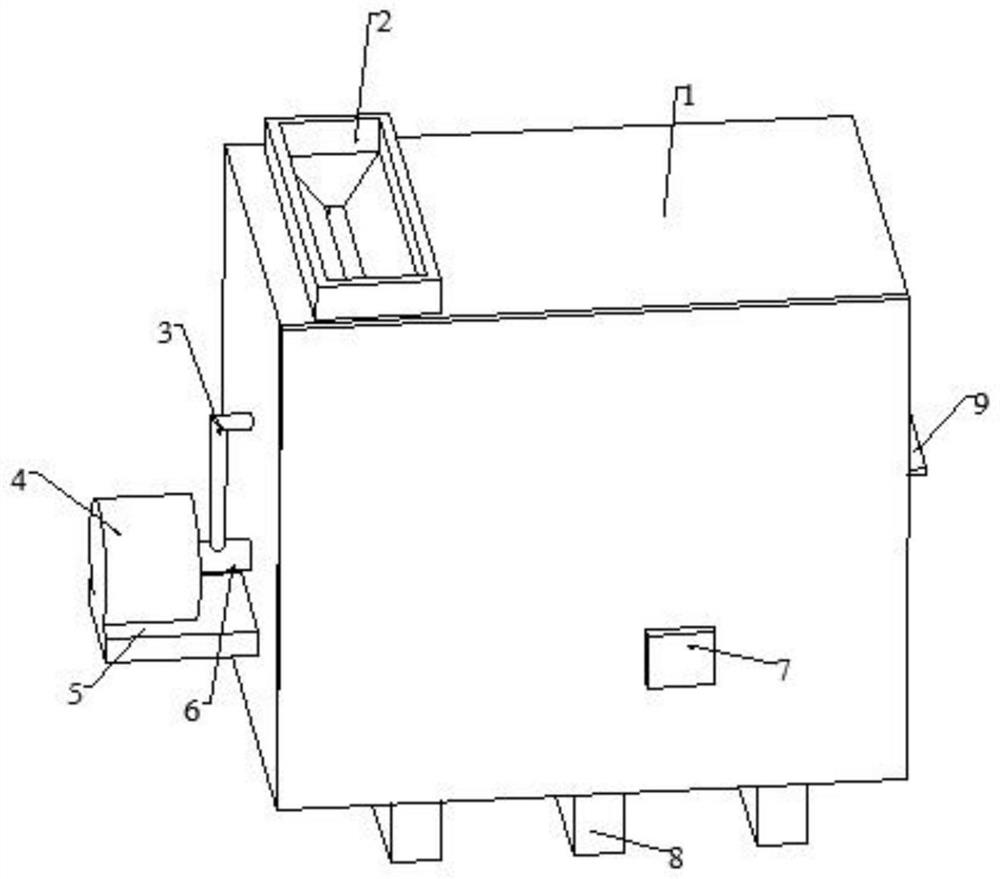

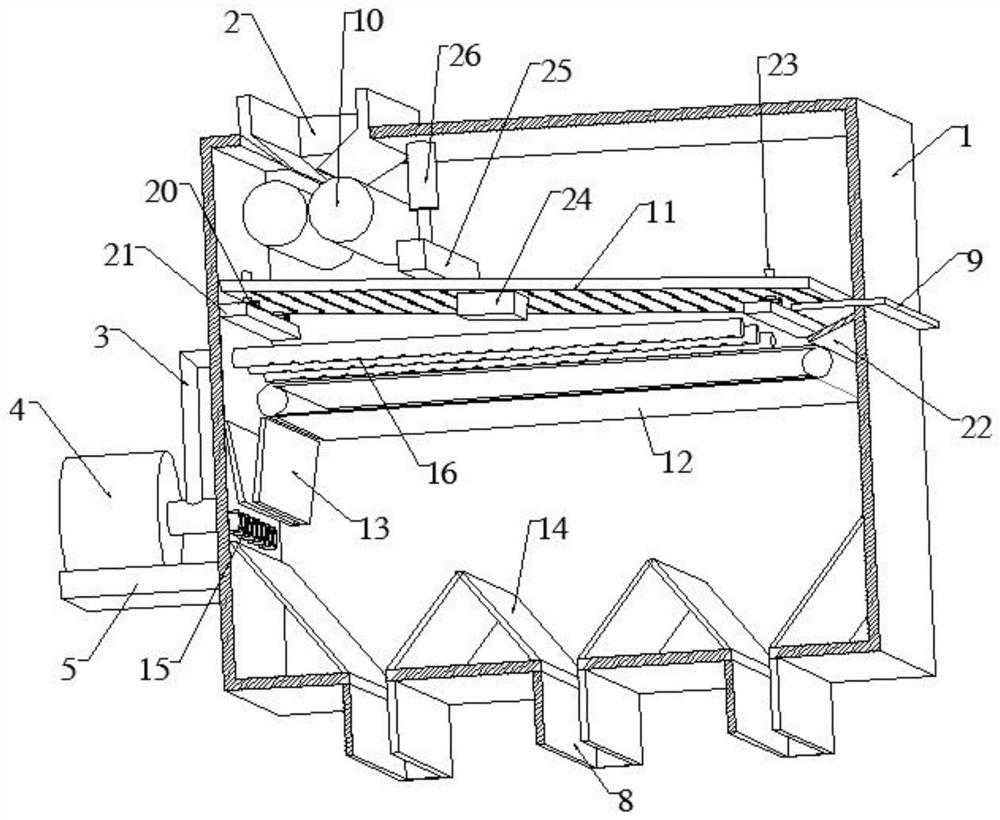

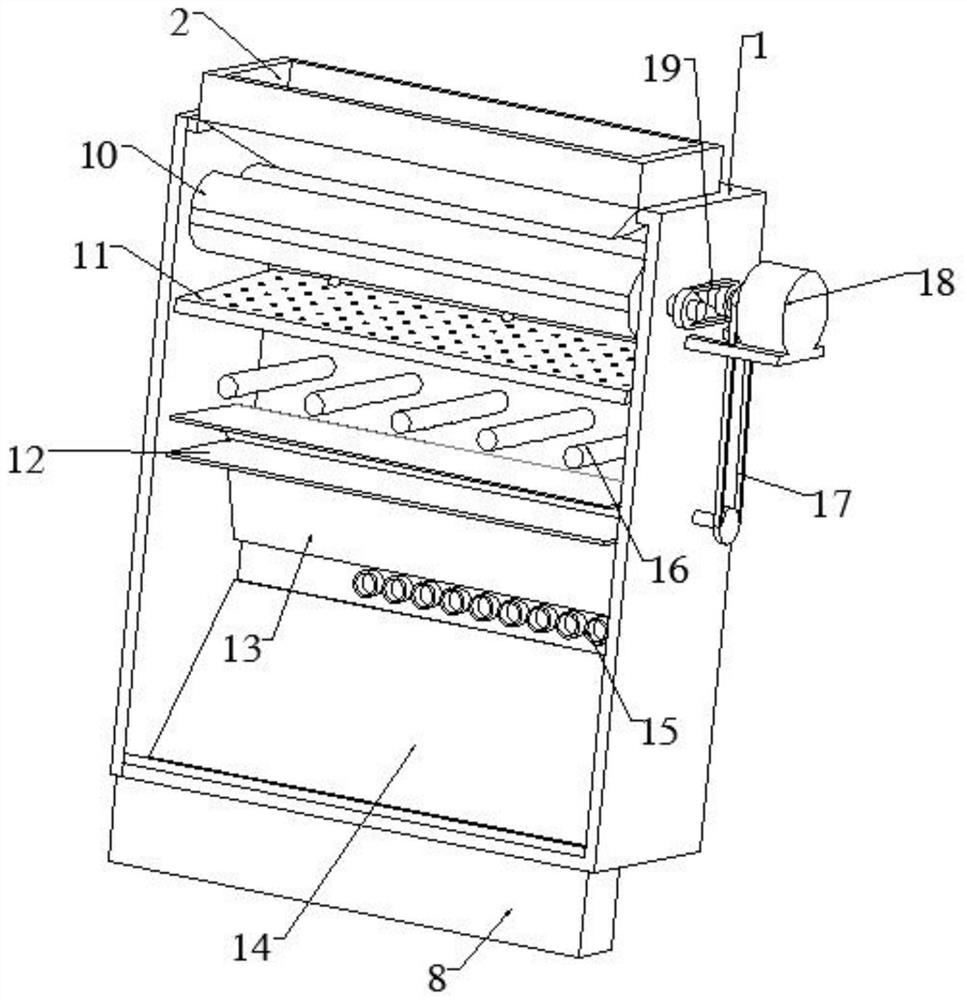

[0038] A screening machine for sampling and analyzing urban waste soil in this embodiment comprises a body 1, a feed hopper 2, a first air outlet pipe 3, a mounting plate 5, a second air outlet pipe 6, a controller 7, a discharge pipe 8, Baffle plate 9, crushing roller 10, filter plate 11, conveyor belt 12, collecting hopper 13, collecting plate 14, nozzle 15, hot air pipe 16, first belt 17, second belt 19, spring 20, support plate 21 , guide plate 22, straight rod 23, vibrator 24, splitter plate 25 and cylinder 26, the top of the body 1 is fixedly connected with the feed hopper 2, and the bottom of the feed hopper 2 is symmetrically equipped with crushing rollers 10, and the initial materials are crushed Crushing, the top of the machine body 1 is fixedly installed with a cylinder 26 on the right side of the crushing roller 10, and the output end of the cylinder 26 is fixedly connected with a splitter plate 25. At the same time, it prolongs the time of materials on the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com