PIN spot-welding mechanism and automobile coil winding spot-welding assembly line

A pin point and water outlet technology, which is applied in the field of PIN pin spot welding mechanism and automobile coil winding spot welding line, can solve the problems of difficult control of solder volume, increase of PIN pin thickness, inconvenient use of coil, etc., and achieve a reasonable distribution of installation space , increase the contact area, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

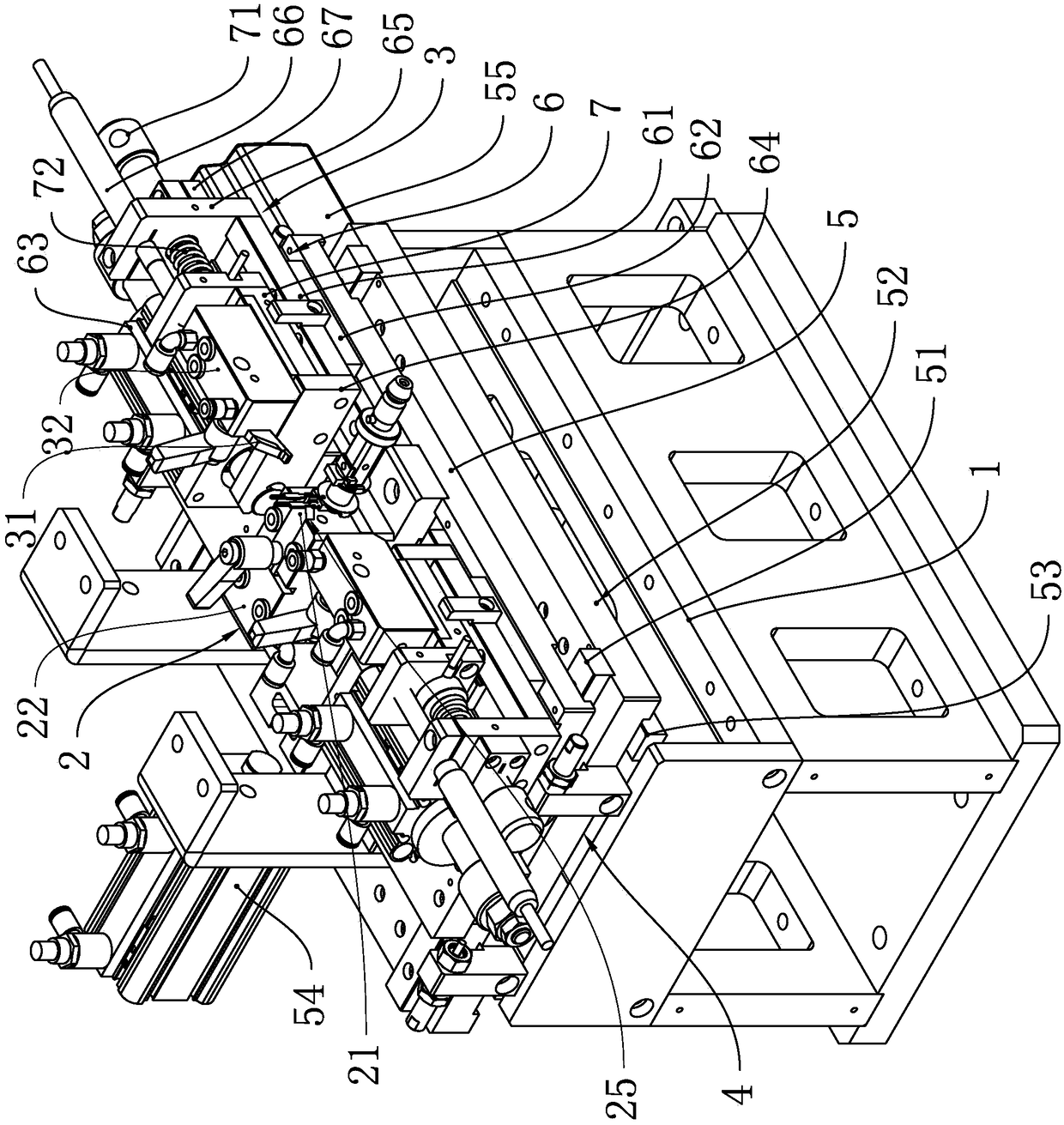

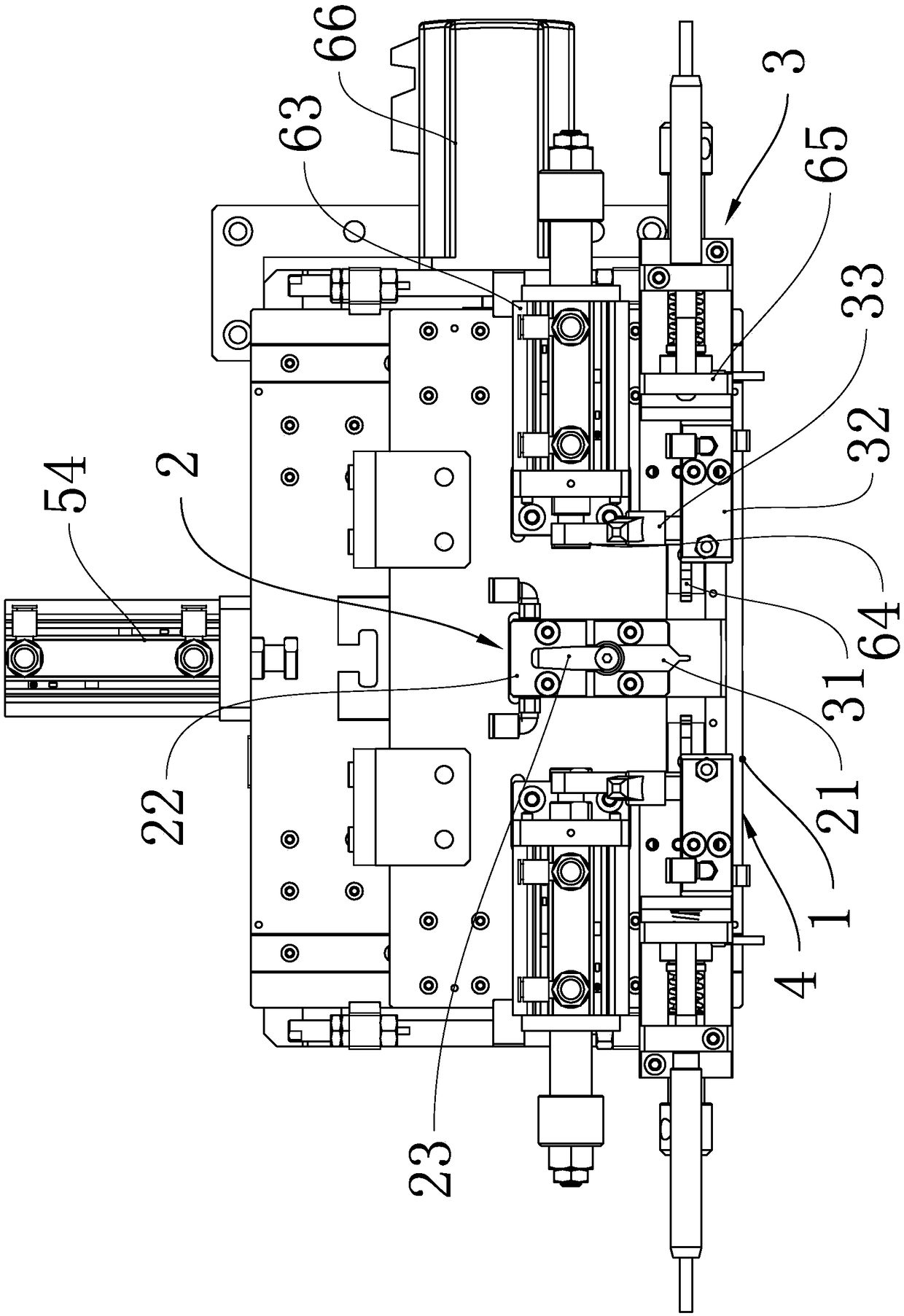

[0027] see figure 1 and figure 2 The PIN needle spot welding mechanism of the present invention includes a bracket 1, a common electrode assembly 2 and two sets of pole assemblies 3 / 4. In this embodiment, the bracket 1 simultaneously supports the common electrode assembly 2 and the two sets of pole assemblies 3 / 4 .

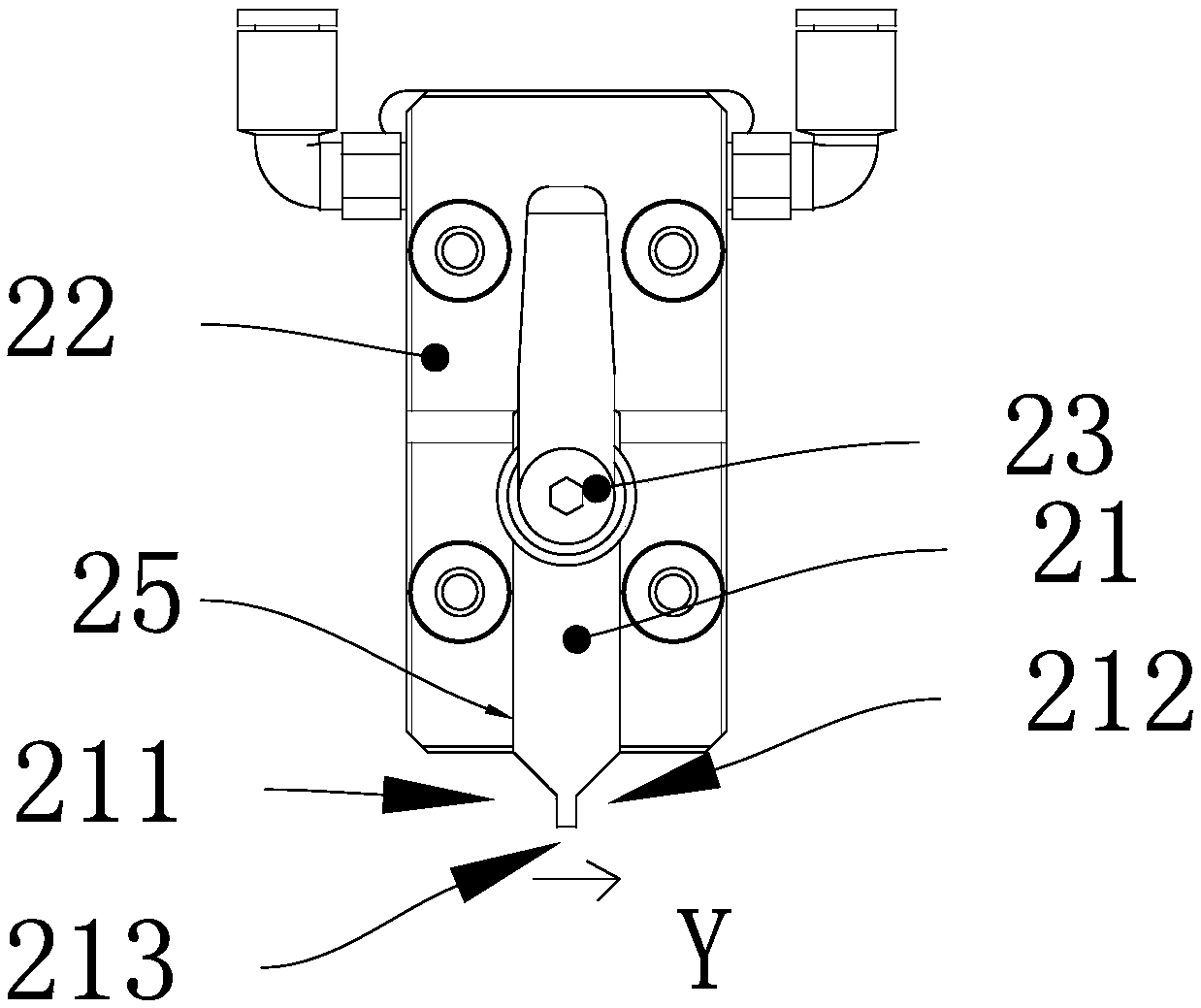

[0028] see image 3 The common electrode assembly 2 includes a common electrode sheet 21 and a common electrode mounting seat 22, the common electrode sheet 21 is arranged on the common electrode mounting seat 22, in this embodiment, the upper end surface of the common electrode mounting seat is provided with a first groove, The common electrode sheet is arranged in the first groove, and the side of the common electrode sheet 21 facing away from the common electrode seat is exposed, so that the first electrical connection part 23 is arranged on the common electrode sheet 21, and the first electrical connection part 23 is used to connect the power supply. . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com