Bolt rust remover and bolt coating procuring method

A rust remover and bolt technology, applied in the direction of grinding/polishing safety devices, grinding machines, portable grinding beds, etc., can solve the problems of low operating efficiency and inconvenient portability, and achieve easy portability, high rust removal efficiency, and reduced direct The effect of economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Such as Figure 4 As shown, according to a kind of bolt coating pre-curing method provided by the present invention, comprising:

[0067] Step S101, using a bolt deruster to derust the bolts;

[0068] Step S102, brushing the primer on the derusted bolts;

[0069] Step S103, sealing the bolts coated with primer with sealant.

[0070] The specific operation process is as follows:

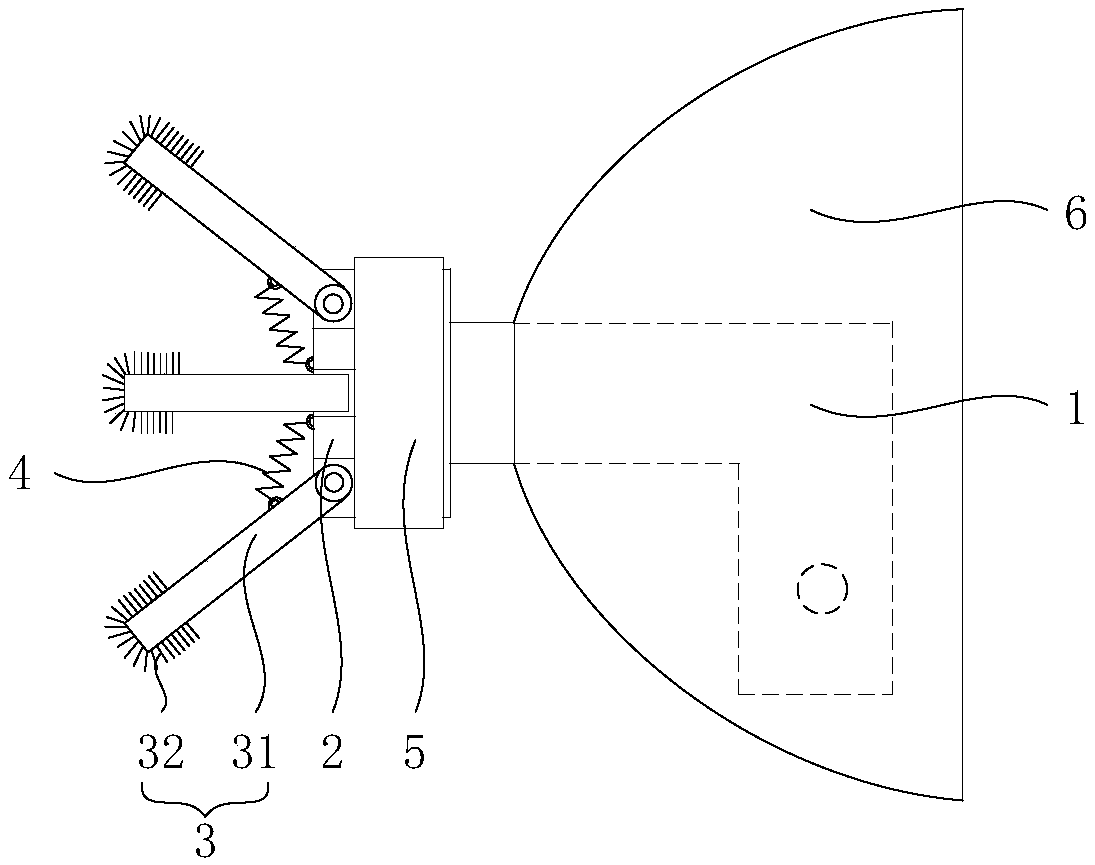

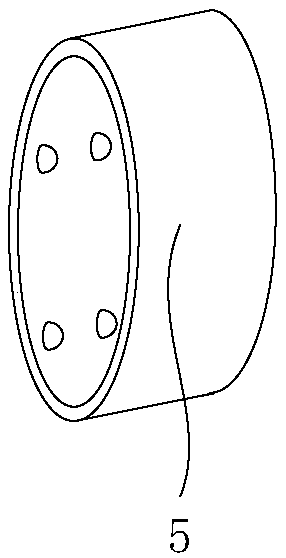

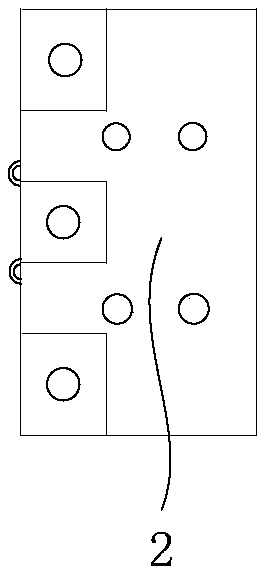

[0071] In step S101, use the bolt rust remover to derust the bolts, hold the handle 1, the motor drives the rotating base 2 to rotate, and the derusting claws 3 on the rotating base 2 derust the bolts; then, in step S102, derust the bolts In the priming of the bolts, the primer is applied to the outer surface of the bolts to isolate the bolts from the outside air; subsequently, in step S103, the sealant is used to seal the primer-coated bolts, and polysulfide is used to seal the bolts. The sealant fills the gap between the bolt and the building.

[0072] Among them, polysulfide sealant has...

Embodiment 2

[0074] Such as Figure 5 As shown, according to a kind of bolt coating pre-curing method provided by the present invention, comprising:

[0075] Step S201, using a bolt rust remover to derust the bolts;

[0076] Step S202, brushing the primer on the derusted bolts;

[0077] Step S203, using a sealant to seal the bolts coated with the primer;

[0078] Step S204, painting the closed bolts with a fluorocarbon topcoat.

[0079] The specific operation process is as follows:

[0080] In step S201, use the bolt rust remover to derust the bolts, hold the handle 1, the motor drives the rotating base 2 to rotate, and the derusting claws 3 on the rotating base 2 derust the bolts; then, in step S202, derust the bolts In the priming of the bolts, the primer is applied to the outer surface of the bolts to isolate the bolts from the outside air; then, in step S203, the sealant is used to seal the primer-coated bolts, and polysulfide is used to seal the bolts. The sealant fills the gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com