Mortar mixing device for construction engineering

A technology for mortar mixing and construction engineering, which is applied in cement mixing devices, control devices, clay preparation devices, etc. It can solve problems such as inability to guarantee uniformity, over-humidity or over-dryness, and dead corners of mixing, so as to avoid static enrichment and avoid The effect of inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

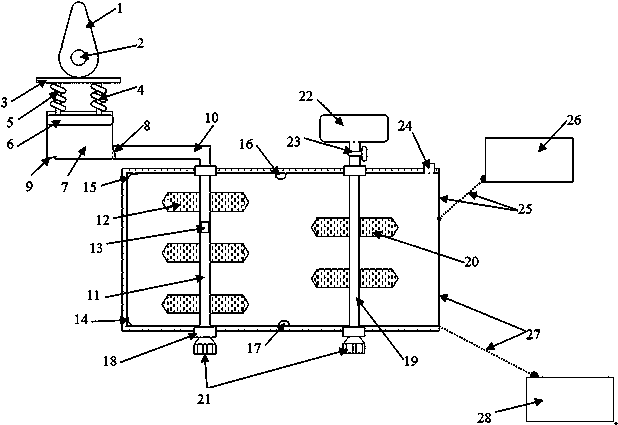

[0034] Such as figure 1 Shown:

[0035] A mortar mixing device for construction engineering, comprising a cam part, a piston cylinder part, a mortar mixing chamber, a water supply part, a feeding tank and a feeding tank.

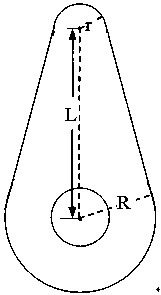

[0036]The cam component includes a cam, a camshaft and a cam drive motor, and the cam is configured as a large wheel and a small wheel and an intermediate body connecting the large wheel and the small wheel, and the large wheel and the small wheel are horizontal cylinders Half, the intermediate body is a trapezoidal platform, and the upper and lower bottom surfaces of the trapezoidal platform are respectively the side planes of the cylinder of the small wheel and the large wheel, wherein the radius of the large wheel of the cam is R, the radius of the small wheel of the cam is r, and the center distance of the cam shaft is L, the relationship between the three satisfies R=2.85r, and L=2R+1.52r, wherein the distance between the center of the camshaft is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com