Preparation apparatus of activated carbon standard material

A standard material and preparation device technology, applied in the direction of carbon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problem of unable to meet the control requirements of uniformity and reproducibility of activated carbon, low temperature control accuracy, and easy occurrence of sandwiches, etc. problem, achieve the effect of shortening the preparation cycle, improving the preparation quality and ensuring the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

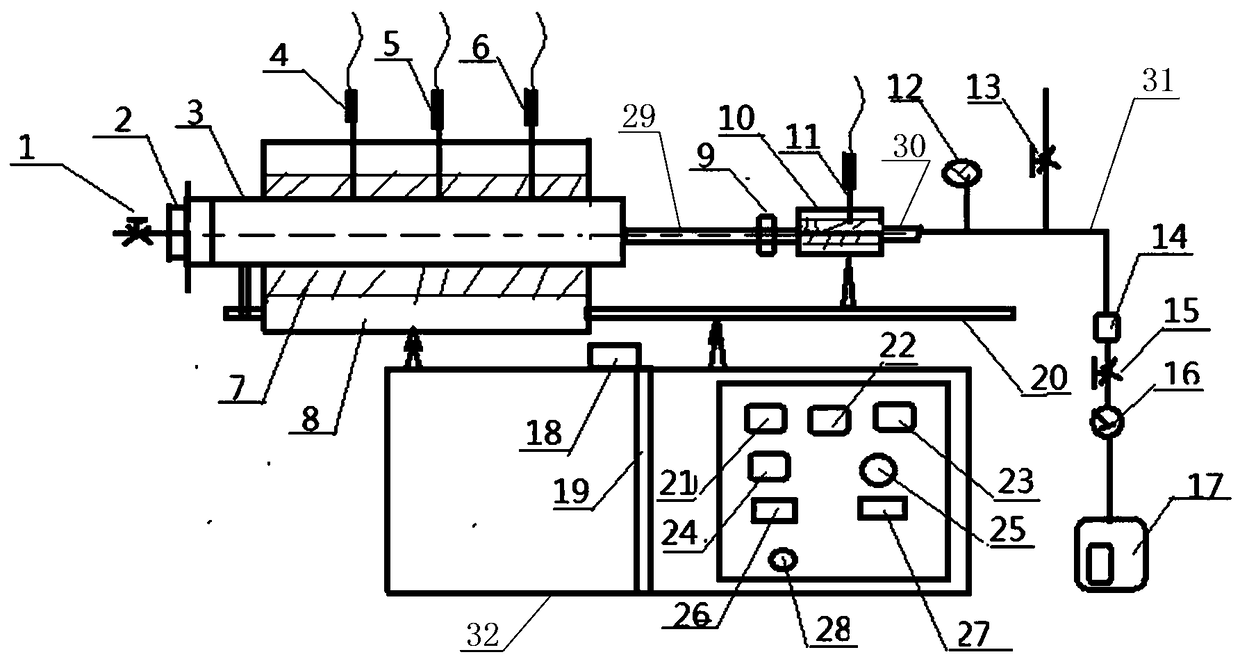

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] An activated carbon standard material preparation device includes a charging pipe, a sealing port, a support, a preheating unit, a pressure measuring unit, a pipeline system, a temperature control unit, and a flow control unit. The specific connection structure is as figure 1 As shown, it includes the charging tube 3, the front end of the charging tube 3 is movably installed on the front of the support frame 20 (to realize the rotation of the charging tube 3), the rear end of the charging tube 3 is fixedly connected with the hollow support tube I29, and the hollow support tube I29 passes through The rotating connector 9 is connected to the hollow support pipe II30 (the function of the rotating connector 9 is to ensure that the charging pipe 3 rotates, but the preheating unit does not rotate). Heat unit 10 and thermocouple IV11; refract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com