River sediment solidifying method implemented based on liquid limit indexes

A technology of river sediment and solidification method, applied in chemical instruments and methods, fixed/solidified sludge treatment, polluted waterway/lake/pond/river treatment, etc. The effect of reducing waste, saving construction period and reducing the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a river channel treatment project in a certain city, the sediment liquid limit was 44.03%, the organic matter content determined by the loss on ignition method was 3.67%, and potassium dichromate was used as an oxidant to measure the COD content of the river water by the colorimetric method to be 84mg / L. When the water content is 39.43%, measure the density of the bottom mud at this time, and use 50kg, 75kg, and 100kg of cement as the curing agent per m³ of bottom soil. After stirring for 3 minutes at a low speed of 62 rpm and 5 minutes at a high speed of 125 rpm with a cement slurry mixer, fill the solidified soil into a semi-open cylindrical plexiglass mold with a diameter of 3.91 cm and a height of 8 cm, and fully vibrate the solidified soil. Mesopores are minimized. Seal it with a sealed bag and put it in a curing box at 20±2°C and humidity greater than 95% for curing. After the solidified soil is molded within 1 to 3 days, it should be demoulded and wrapped wit...

Embodiment 2

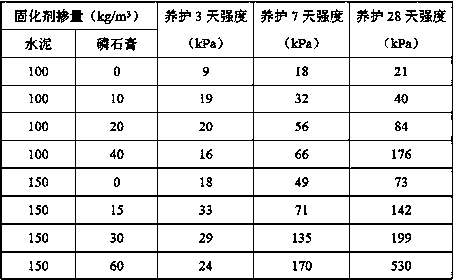

[0024] In a river system improvement project in a certain city, the sediment liquid limit was 38.45%, the organic matter content determined by the loss on ignition method was 3.98%, and the COD content of the river water measured by the colorimetric method using potassium dichromate as an oxidant was 164mg / L. When the water content is 57.68%, measure the density of the bottom mud at this time, use 100kg cement and 100kg cement respectively add 10kg, 20kg, 30kg phosphogypsum as curing agent per m³. The manufacturing process, the curing method and the determination of the curing index are all the same as in Example 1.

[0025] The results show that the amount of curing agent is 100kg / m 3 At the age of 28 days, it still does not meet the strength required for landfill; the amount of curing agent is 110kg / m 3 , the 7-day age strength can reach 137kPa; the curing agent dosage is 120kg / m 3 When the age of 7 days can reach 82kPa; the amount of curing agent is 130kg / m 3 , the 7-day...

Embodiment 3

[0027] In a river system improvement project in a city, the sediment liquid limit was 44.03%, the organic matter content determined by the loss on ignition method was 3.67%, and the COD content of the river water measured by the colorimetric method was 84mg / L with potassium dichromate as the oxidant. When the water content is 66.05%, measure the density of the bottom mud at this time, use 100kg cement and 100kg cement respectively add 10kg, 20kg, 30kg phosphogypsum as curing agent per m³. The manufacturing process, the curing method and the determination of the curing index are all the same as in Example 1.

[0028] The results show that the amount of curing agent is 100kg / m 3 At the age of 28 days, it still does not meet the strength required for landfill; the amount of curing agent is 110kg / m 3 , the 7-day age strength can reach 50kPa, which does not meet the landfill requirements, and the 28-day age strength is 316kPa; the curing agent dosage is 120kg / m 3 When the age of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com