A method for producing jujube fruit vinegar beverage by using jujube distilled wine by-products

A technology for fruit vinegar beverage and by-products, which is applied in the field of producing jujube fruit vinegar beverage and can solve the problems of poor sensory quality and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

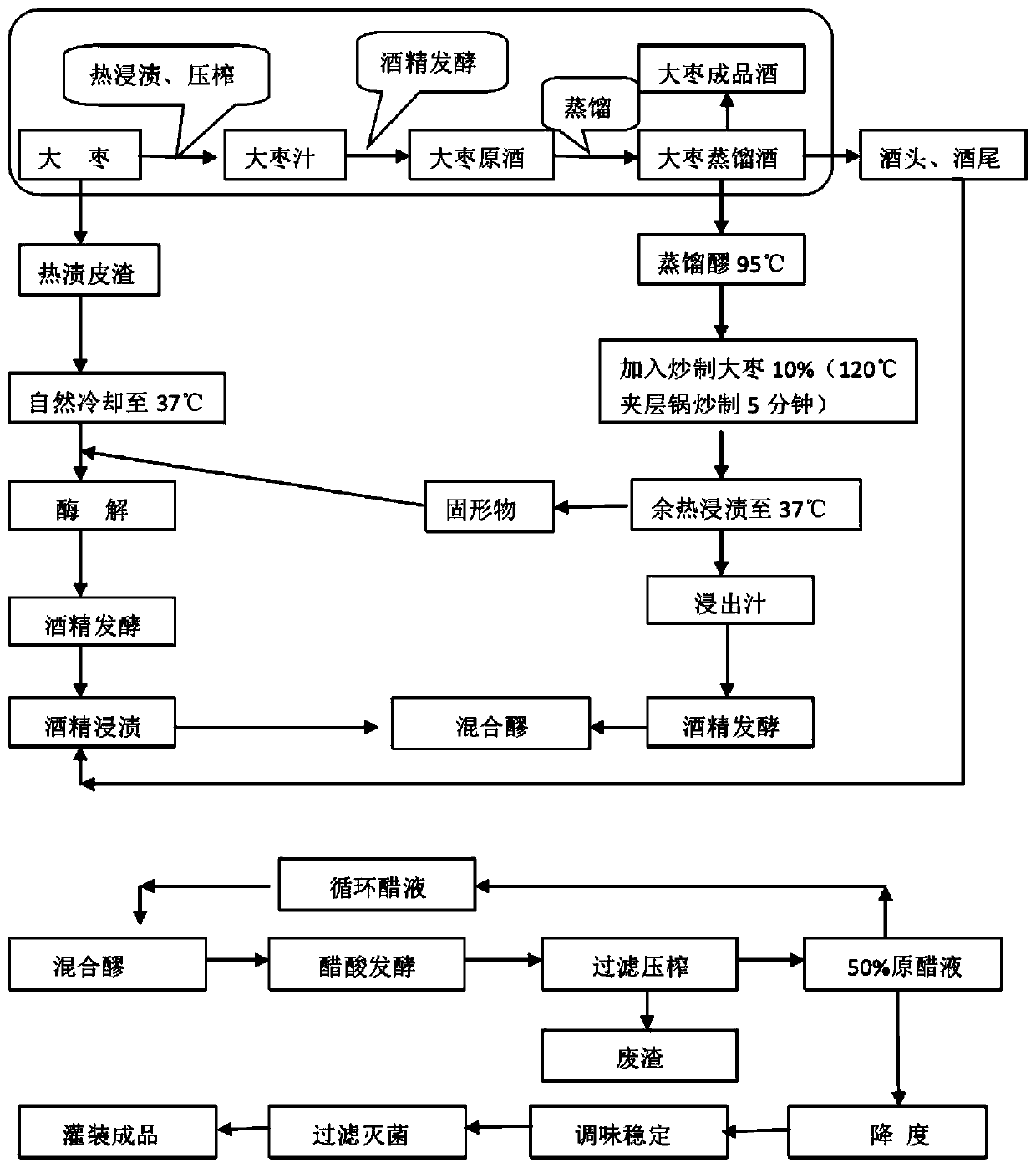

Method used

Image

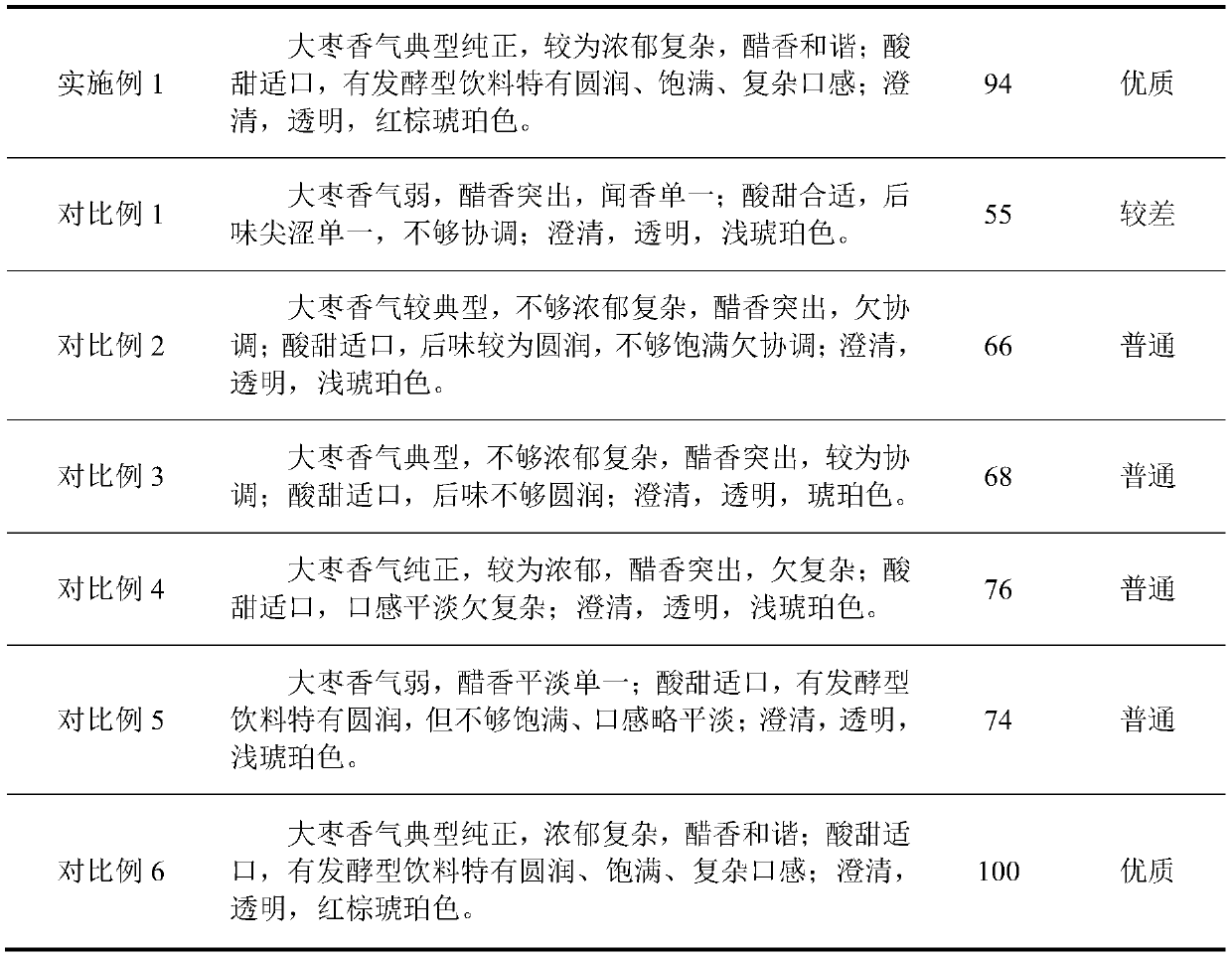

Examples

Embodiment 1

[0041] Step 1: In 5000kg of distilled mash, add 500kg of roasted dried jujube (fried in a sandwich pot at 120°C for 5 minutes), and use the residual heat of the distilled mash to impregnate. After the mash was naturally cooled to 37°C, 110 g of C-MAX pectinase was added for enzymatic hydrolysis for 24 hours. Squeeze to get the solid a, extract the juice c.

[0042] Step 2: Heat-soak 2400kg of pomace and cool naturally to 37°C, add 48g of C-MAX pectinase for enzymatic hydrolysis for 24 hours. Obtain enzymolysis mixture b.

[0043] Step 3: Mix the above solid matter a and the enzymatic hydrolysis mixture b. Inoculate 0.68kg of M1 yeast and carry out alcoholic fermentation at 25°C-30°C. After the alcoholic fermentation is finished, add 30kg of wine head and 200kg of wine tail to carry out alcohol maceration for 24 hours.

[0044] Step 4 extract juice c, inoculate 0.90kg of M1 yeast to carry out alcoholic fermentation. After the alcoholic fermentation is finished, it is mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com