Method for improving filler retention rate and paper evenness under the condition of high shear force

A high-shear, paper technology, applied in the field of improving paper strength, can solve problems such as paper strength decline, and achieve the effects of improving evenness, reducing impact, and reducing fiber flocculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

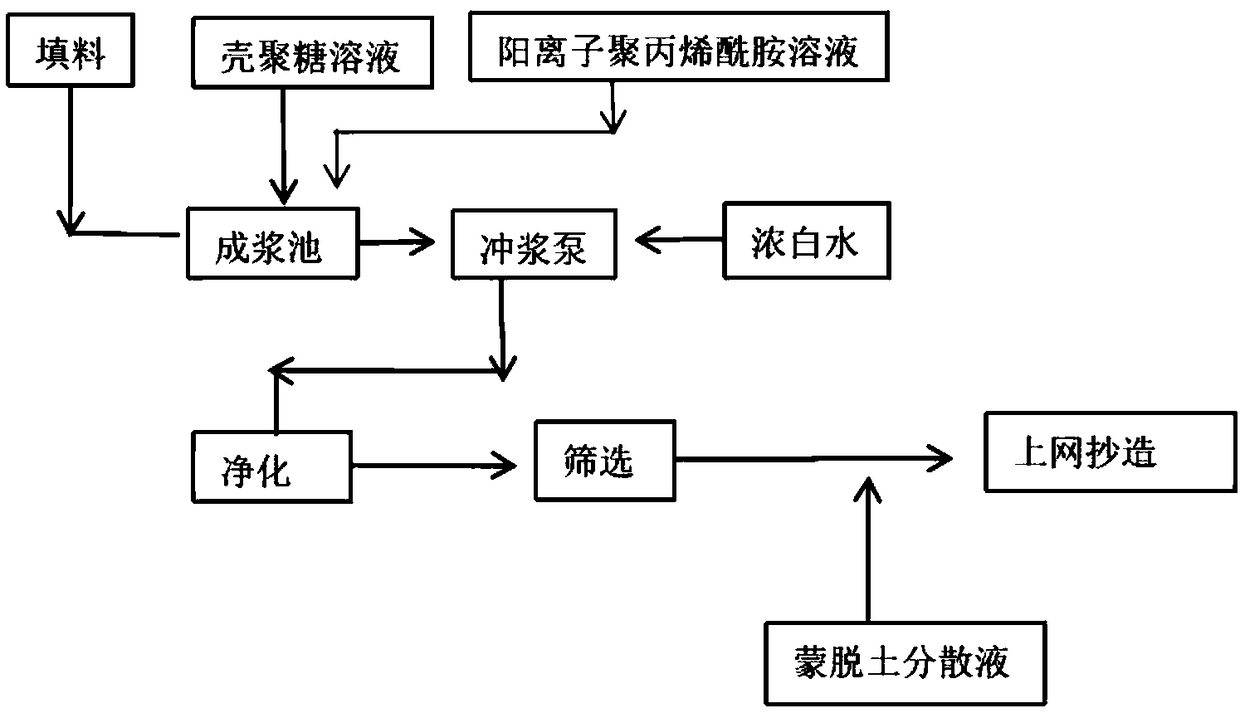

[0015] According to the amount of chitosan: the ratio of bentonite is 0ppm: 0ppm; 1000ppm: 0ppm; 1000ppm: 3000ppm three different ratios are added to the paper material; the ratio of the paper material is softwood pulp: hardwood pulp: waste paper pulp is 15% : 50%: , 35%, the amount of filler calcium carbonate added is 30% (relative to the amount of dry fiber), the concentration of montmorillonite is 0.3%, according to figure 1 The process flow shown is added, the chitosan solution is added to the slurry tank, and white water is added to dilute the slurry. After the high-shearing of the pulping pump, the montmorillonite dispersion was added, and the slurry was sprayed on the net for papermaking; and the influence on the retention and drainage properties of the paper material and the physical properties of the paper was determined.

[0016] Table 1 is the comparison of the application effect of chitosan unit retention system and chitosan / montmorillonite particle retention syste...

example 2

[0021] According to the amount of chitosan: the ratio of bentonite is 0ppm: 0ppm; 1000ppm: 0ppm; 1000ppm: 3000ppm three different ratios are added to the paper material; the ratio of the paper material is softwood pulp: hardwood pulp: waste paper pulp is 15% : 50%: , 35%, the amount of filler calcium carbonate added is 30% (relative to the amount of dry fiber), the concentration of montmorillonite is 0.8%, according to figure 1 The technological process shown is added, and the influence on the retention and drainage performance of paper stock and the physical properties of paper is determined.

[0022] Table 2

[0023]

[0024] Comparing the table data in Table 2, it can be concluded that the chitosan / montmorillonite particulate retention system can not only improve the retention and uniformity of fillers, but also improve the tensile strength of paper. The increase of montmorillonite concentration can increase the filler retention rate, but the formation index and tensile...

example 3

[0026] The dosages of chitosan / montmorillonite are 0.1% and 0.3% respectively; the dosages of cationic polyacrylamide / chitosan / montmorillonite are 0.05%, 0.05% and 0.3% respectively. The amount of filler calcium carbonate added is 30% (relative to the amount of dry fiber), according to figure 1 The process flow shown is added, and the influence on the retention and drainage properties of the paper material and the physical properties of the paper is determined.

[0027] Table 3 is the comparison of the application effects of chitosan / montmorillonite particle retention system, chitosan / cationic polyacrylamide / montmorillonite system and cationic polyacrylamide / montmorillonite system.

[0028] table 3

[0029]

[0030] Comparing the table data in Table 3, it can be concluded that the chitosan / montmorillonite system and the chitosan / cationic polyacrylamide / montmorillonite system can not only improve the retention rate of fillers, improve evenness, but also have a negative impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com