Directional support and reinforcement method of stratiform surrounding rock tunnel in high ground stress environment

A technology with high in-situ stress and surrounding rock, applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of affecting construction progress, waste of project investment, consumption, etc., and achieve the goal of speeding up construction progress, saving project investment, and reducing design changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

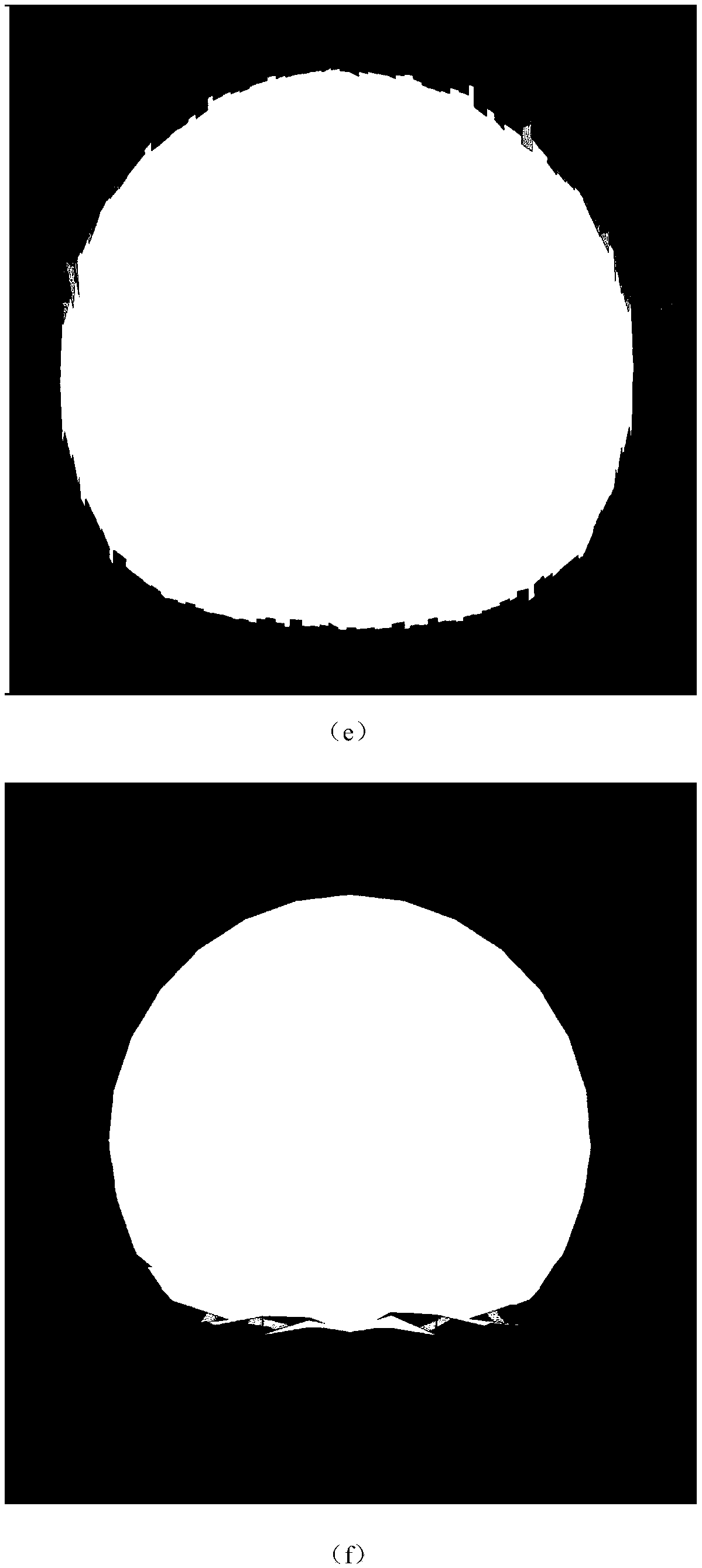

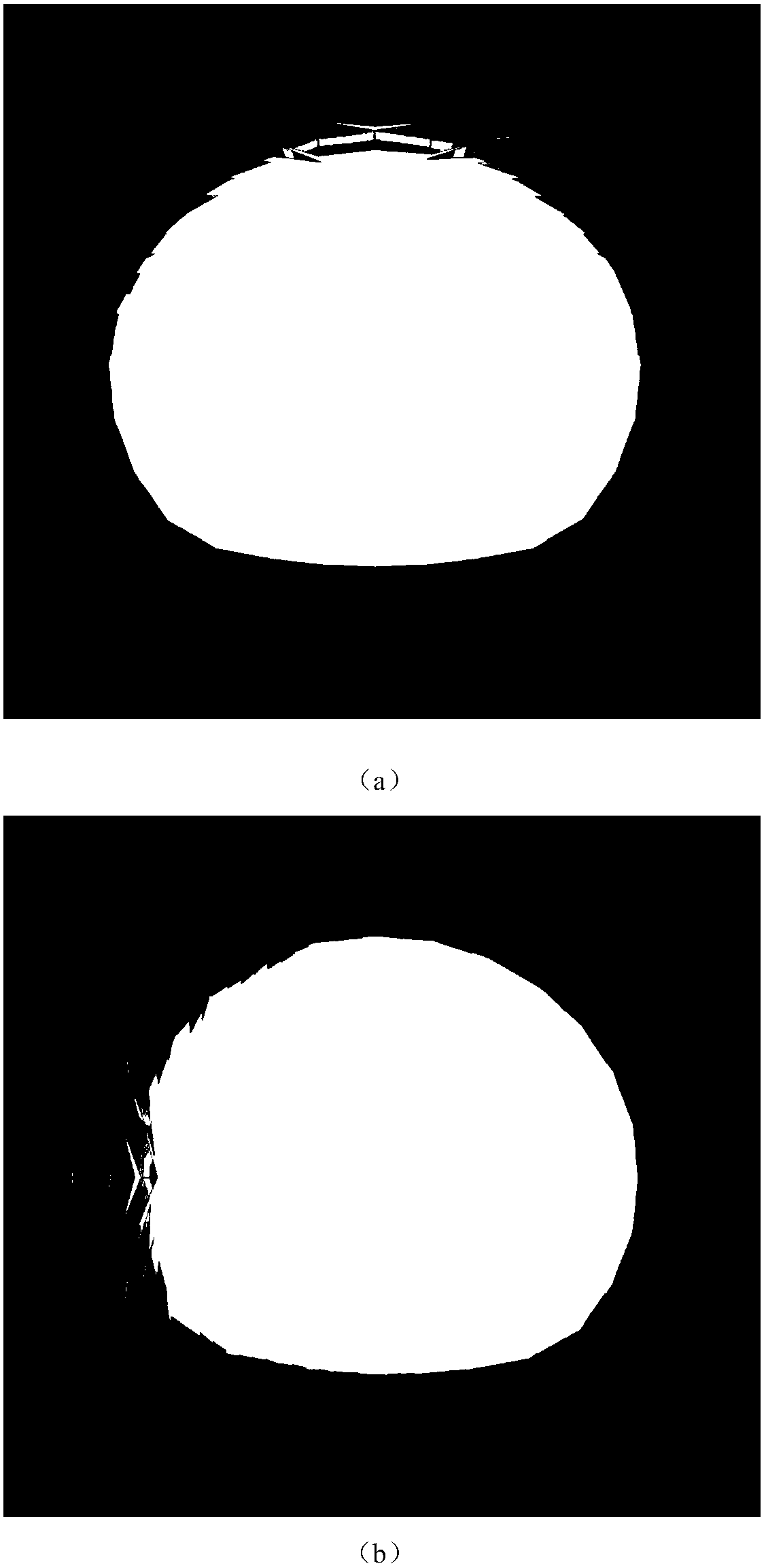

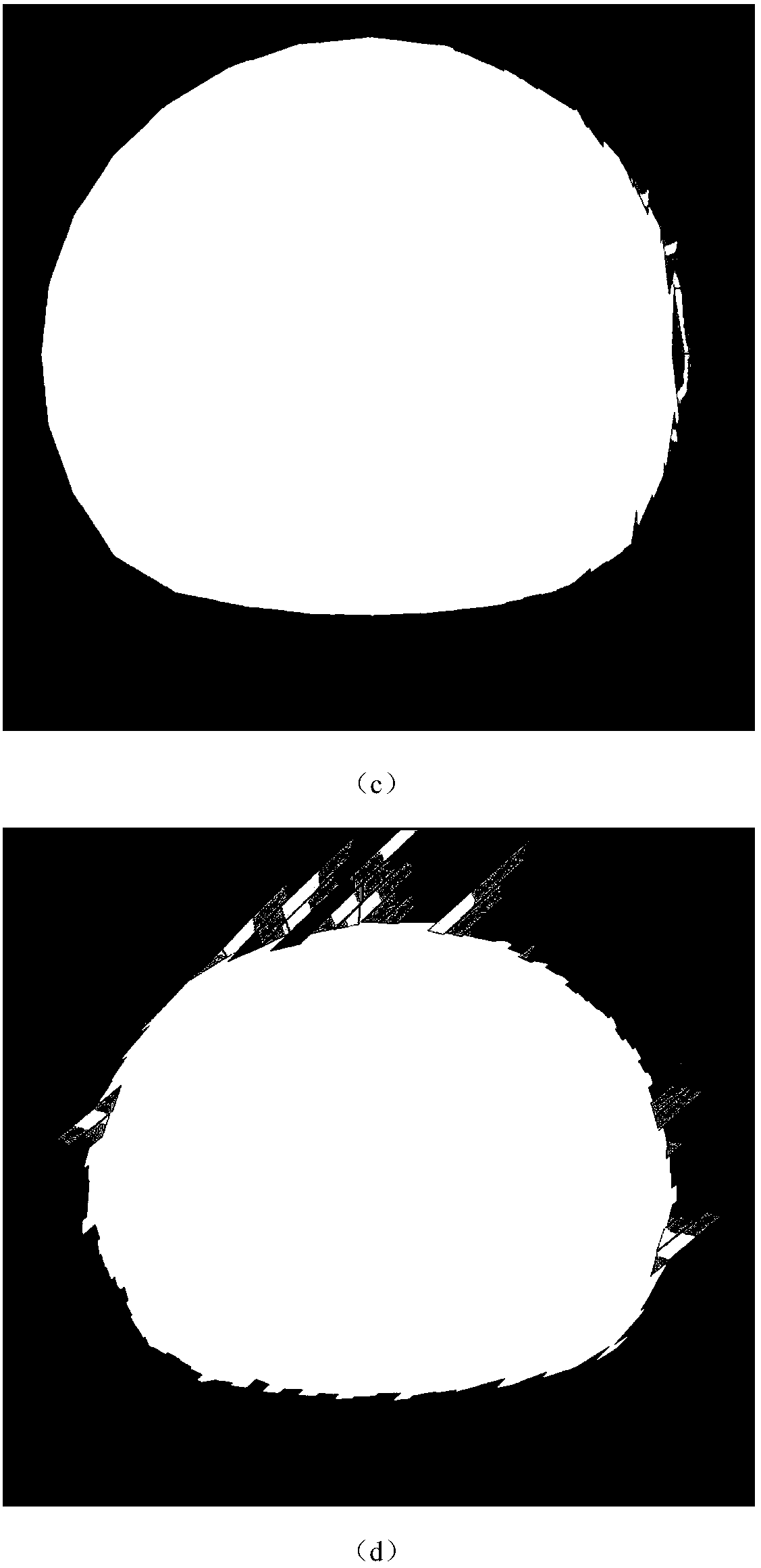

Image

Examples

Embodiment Construction

[0028] In order to make the objects and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0029] An embodiment of the present invention provides a method for directional support and reinforcement of layered surrounding rock tunnels in high ground stress environments, including the following steps:

[0030] Step 1. Carry out on-site geological cataloging of the tunnel to be reinforced to obtain the in-situ strength characteristics of the structural plane, collect surrounding rock samples to make multiple sets of cylindrical standard test pieces, each set shall have no less than 3 samples, and use triaxial tests to obtain each set of samples separately The following rock mechanics parameters are: elastic modulus, Poisson's ratio, compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com