Mobile automatic washing device and method of air conditioner and air conditioner

A mobile air conditioner and automatic cleaning technology, applied in the direction of cleaning heat transfer devices, air conditioning systems, flushing, etc., can solve the problem of inability to clean the dust of heat exchanger fins, achieve simple and easy structure, realize automatic judgment and control, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

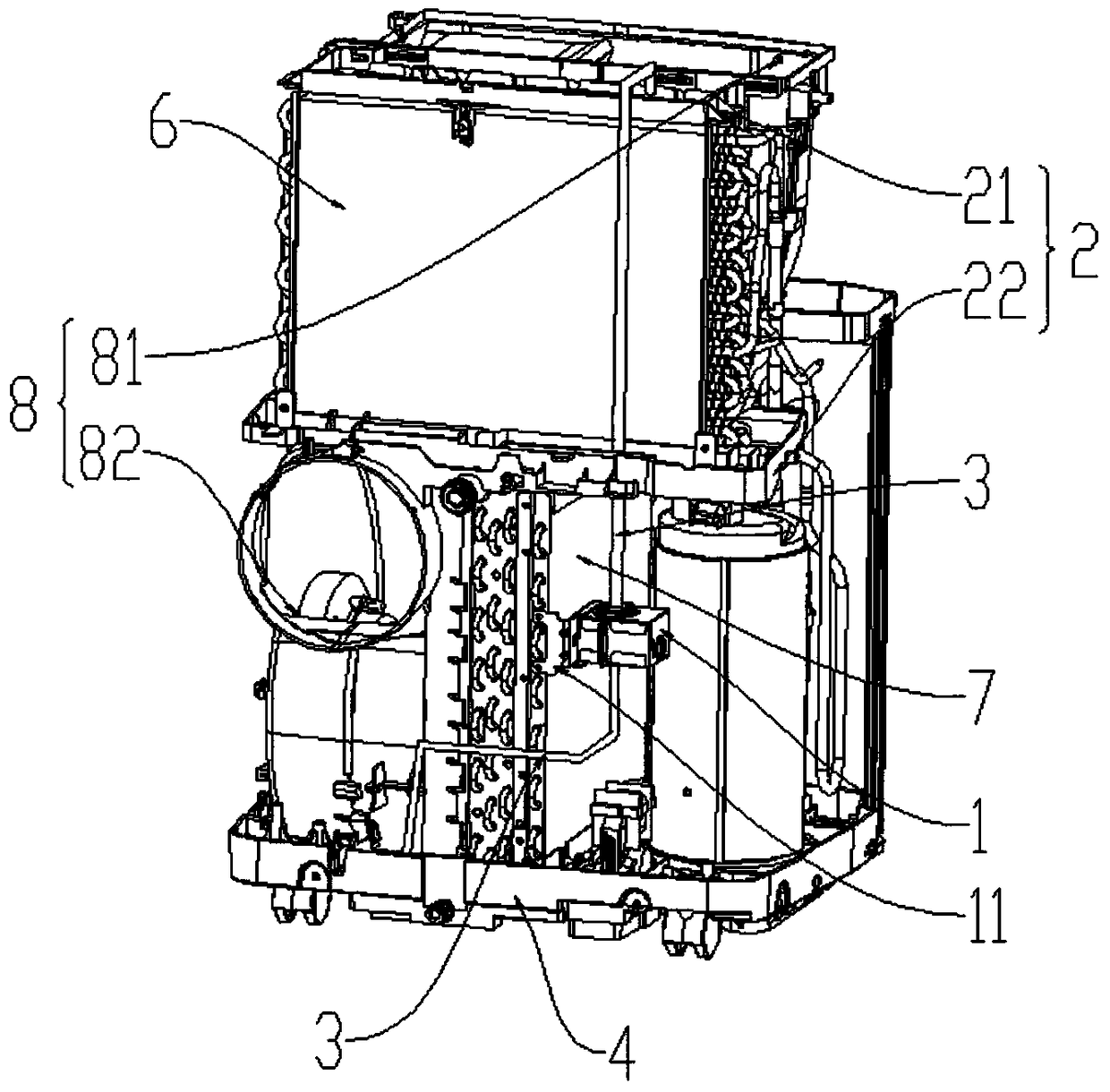

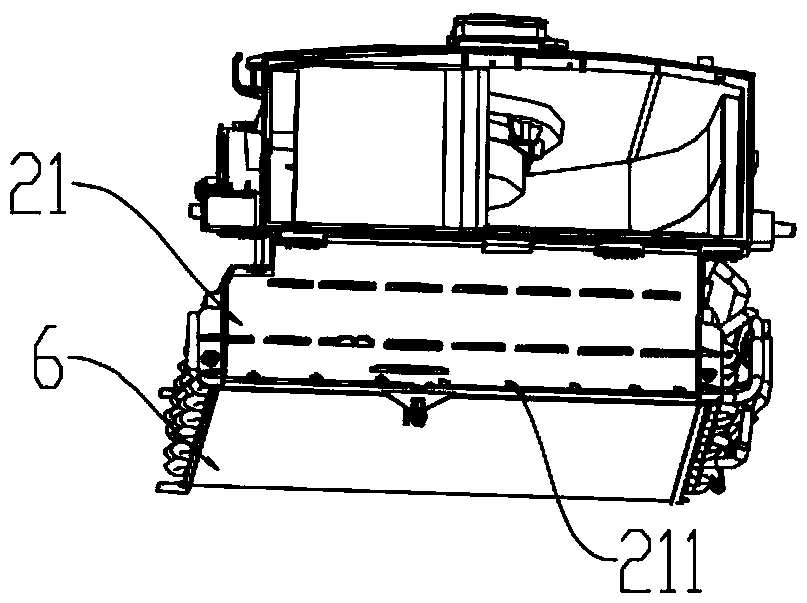

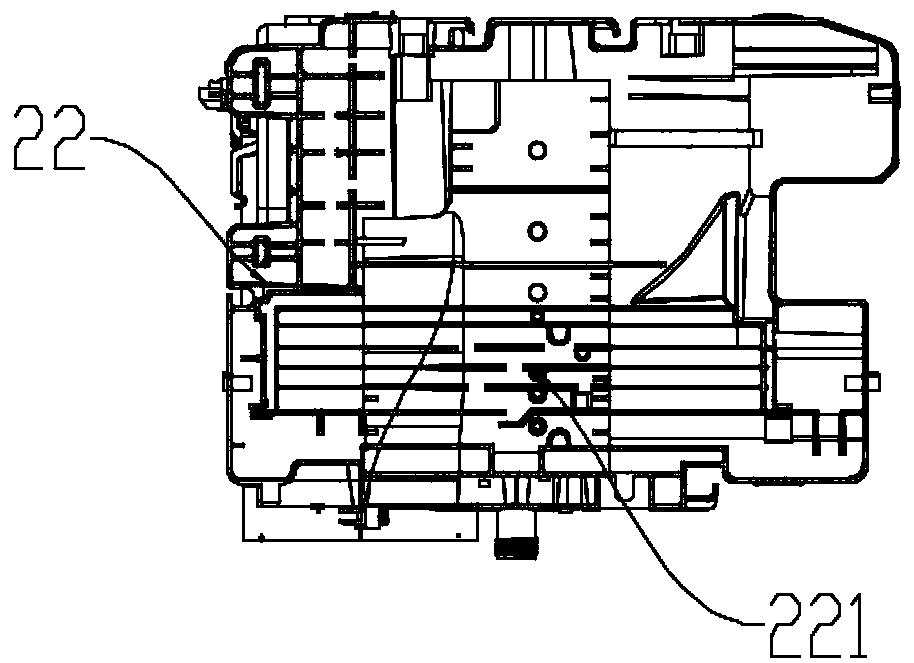

[0037] This embodiment provides a mobile air conditioner automatic cleaning device, such as Figure 1-Figure 3 As shown, it specifically includes a water pump 1, a sprinkler plate 2 and a water pipe 3. An evaporator 6 and a condenser 7 are arranged in the mobile air conditioner, and the evaporator 6 is arranged above the condenser 7. The length direction is consistent, the length direction of the condenser 7 is perpendicular to the length direction of the chassis 4, one end of the water pipe 3 is arranged in the chassis 4, and the condensed water generated by the mobile air conditioner during operation drops into the chassis 4, and the water pipe 3 is arranged on the bottom of the chassis 4 One end is arranged in the water receiving tray of the chassis 4, the other end of the water pipe 3 is connected to the sprinkler tray 2, and the sprinkler tray 2 is arranged on the top of the evaporator 6 and the condenser 7. Preferably, in this embodiment, the condenser 7 and the evaporato...

Embodiment 2

[0041] The difference between this embodiment and the above-mentioned embodiment is that, in combination with image 3 and Figure 4As shown, the mobile air conditioner automatic cleaning device also includes a water level switch 5 and a control module, the control module receives the on or off signal transmitted by the water level switch 5 and controls the on or off of the water pump 1, the control module is electrically connected to the water pump 1, and the control module can send Turn on or off commands to the water pump 1 to control the opening and closing of the water pump 1. The water level switch 5 is arranged in the chassis 4 to detect the water level of the condensed water in the chassis 4. The water level switch 5 is electrically connected to the control module. The switch 5 transmits the detected water level height to the control module for judgment and control. Preferably, there are two water level switches 5, the first water level switch 51 is set with the first ...

Embodiment 3

[0044] The difference between this embodiment and the above-mentioned embodiment is that, in combination with figure 1 and Figure 5 As shown, the mobile air conditioner automatic cleaning device also includes a wind pressure sensor 8, the wind pressure sensor 8 is arranged in the upper air duct and the lower air duct of the mobile air conditioner, and the wind pressure sensor 8 is electrically connected to the control module. The wind pressure sensor 8 includes a first wind pressure sensor 81 and a second wind pressure sensor 82. The first wind pressure sensor 81 is arranged in the upper air passage for detecting the first wind pressure at the air outlet. pressure information, the second wind pressure sensor 82 is arranged in the downwind duct, and is used to detect the second wind pressure information at the entrance, and transmit the first wind pressure information and the second wind pressure information to the control module, and the control module detects the first wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com