Test bed for verifying function of TBM tool changing robot

A technology of robots and test benches, applied in the testing of machines/structural components, instruments, measuring devices, etc., can solve the problems of high time consumption, human damage, confidentiality of research results and progress, etc., and achieve the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

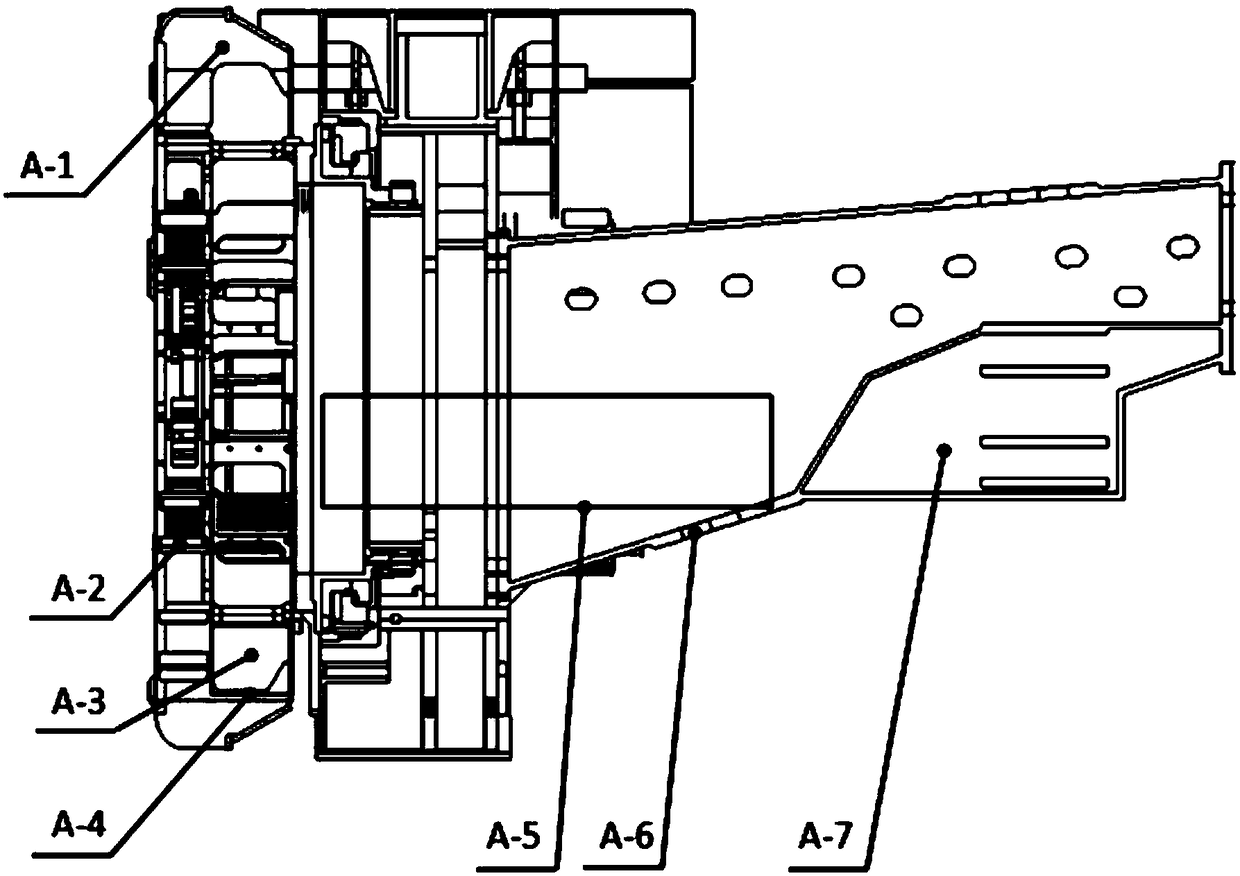

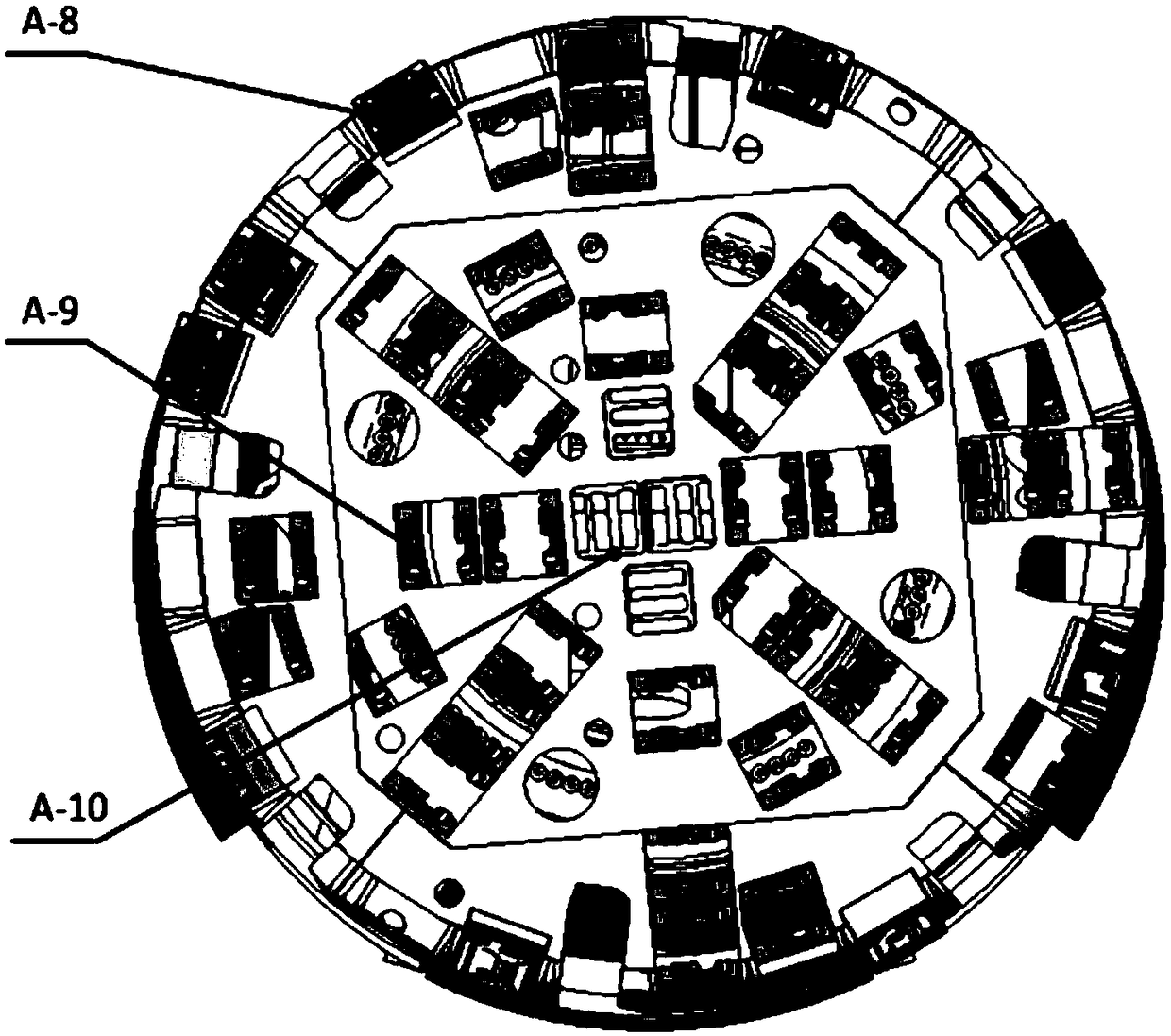

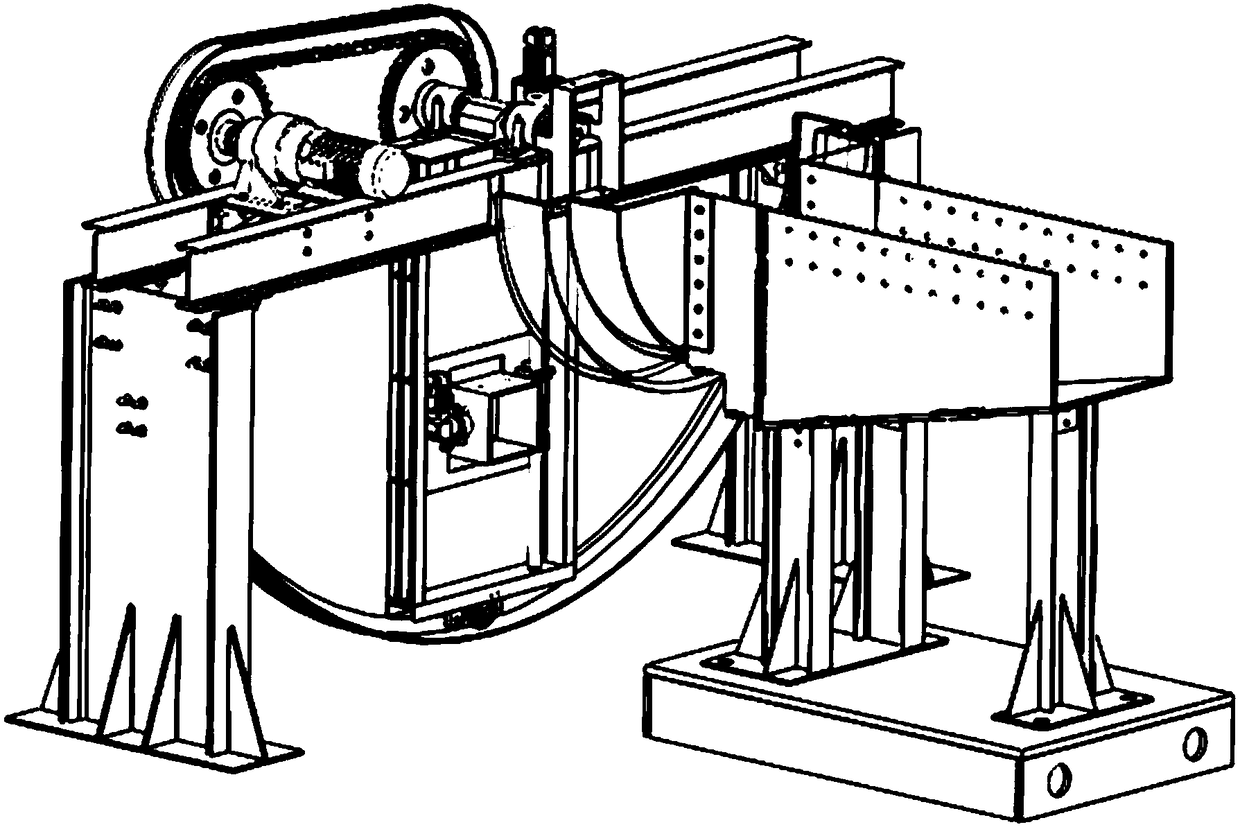

[0042] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions. The main purpose of the present invention is to provide a hob that simulates different poses of a real TBM, so as to test the relevant functions and efficiency of the tool changing robot.

[0043] First of all, the tool changing robot can only be installed on the robot interface G-1 on the main beam. At the same time, the upper part of the robot cannot exceed the top surface of the main beam to meet the basic space constraints, which is also the basic condition for the tool changing robot to be installed in the real TBM environment. . In addition, no matter how the robot moves, it cannot collide with the test bench and can cross the flange simulation part G-3. When the tool is changed at the same time, the hob can only be transported through the tool hole G-7, and other paths are not allowed.

[0044] The second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com