NdFeB permanent magnet material for magnetic levitation system and preparation method thereof

A permanent magnet material, NdFeB technology, applied in magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve problems such as complex grain boundary structure, reduced magnetic properties of materials, limited mechanical properties of NdFeB materials, etc. , to achieve the uniform structure of each component of the alloy, improve the magnetic properties, and improve the effect of comprehensive magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

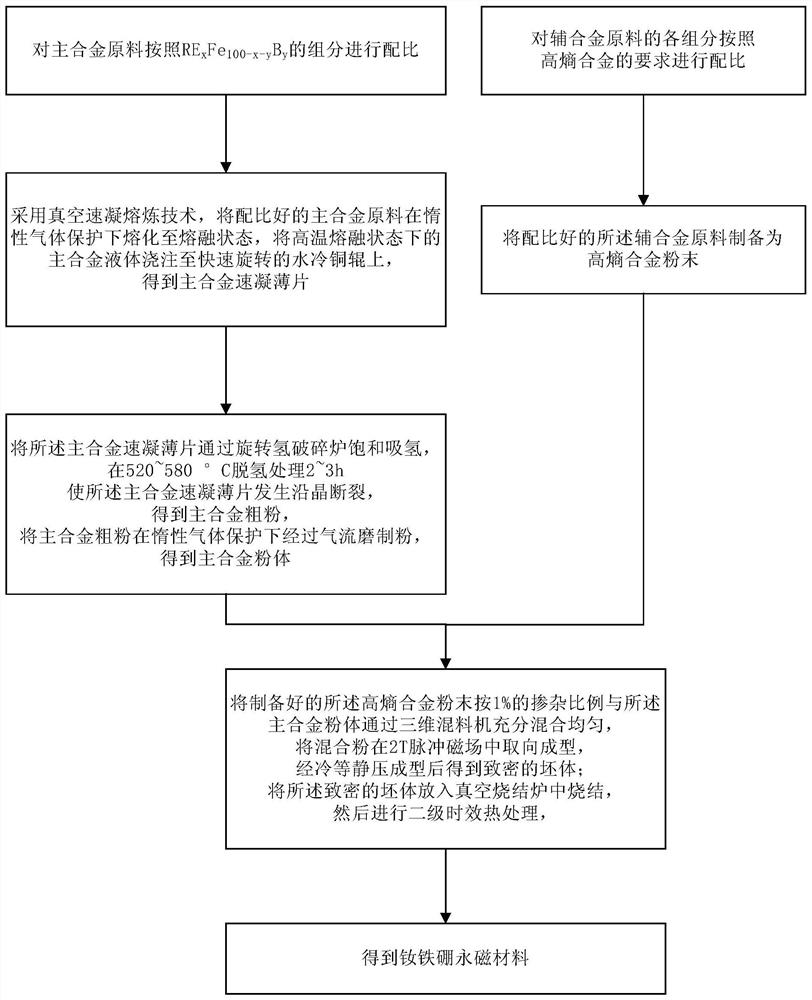

Method used

Image

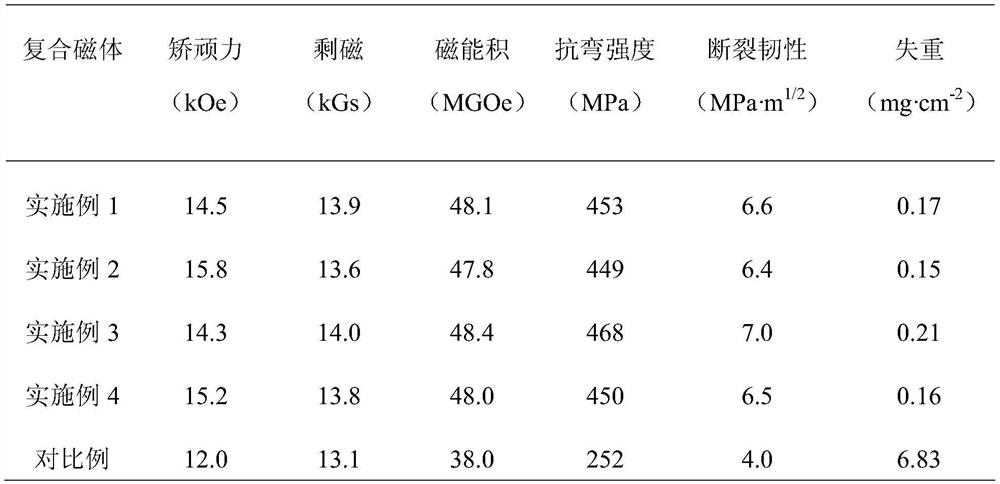

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

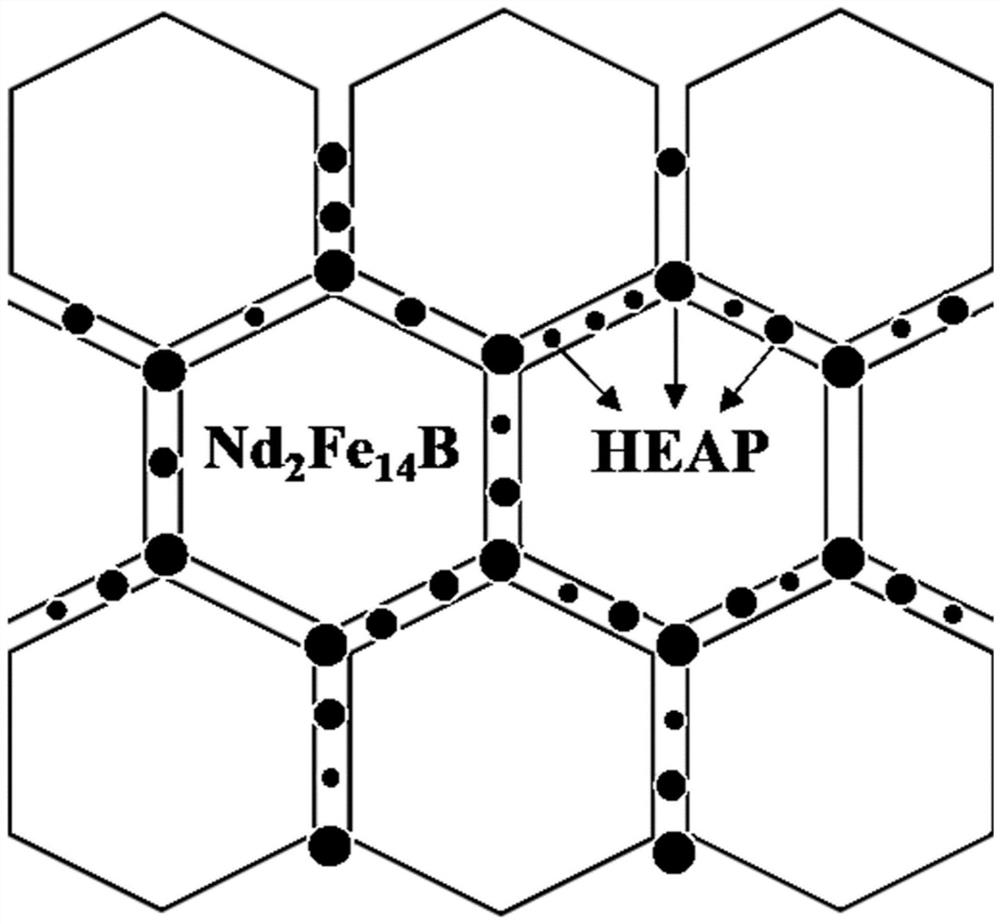

[0035] The high-entropy alloy introduced in the present invention is a new alloy design scheme. High-entropy alloys have many excellent properties that traditional alloys do not have. High-entropy alloys are a class of new materials with great potential. High-entropy alloys generally include multi-component alloys, which are composed of at least 5 metals or combinations of at least 5 metals and non-metals. The mole fraction of each constituent element of the high-entropy alloy is relatively large, and the content of each main element is in the range of about 5% to 35% (at%). Generally, the preparation of high-entropy alloys can be realized by vacuum arc melting or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com