Method for peeling off flexible substrate and display panel

A flexible substrate and backplane technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of low success rate, damage to the entire flexible OLED display panel, scratches or even punctures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

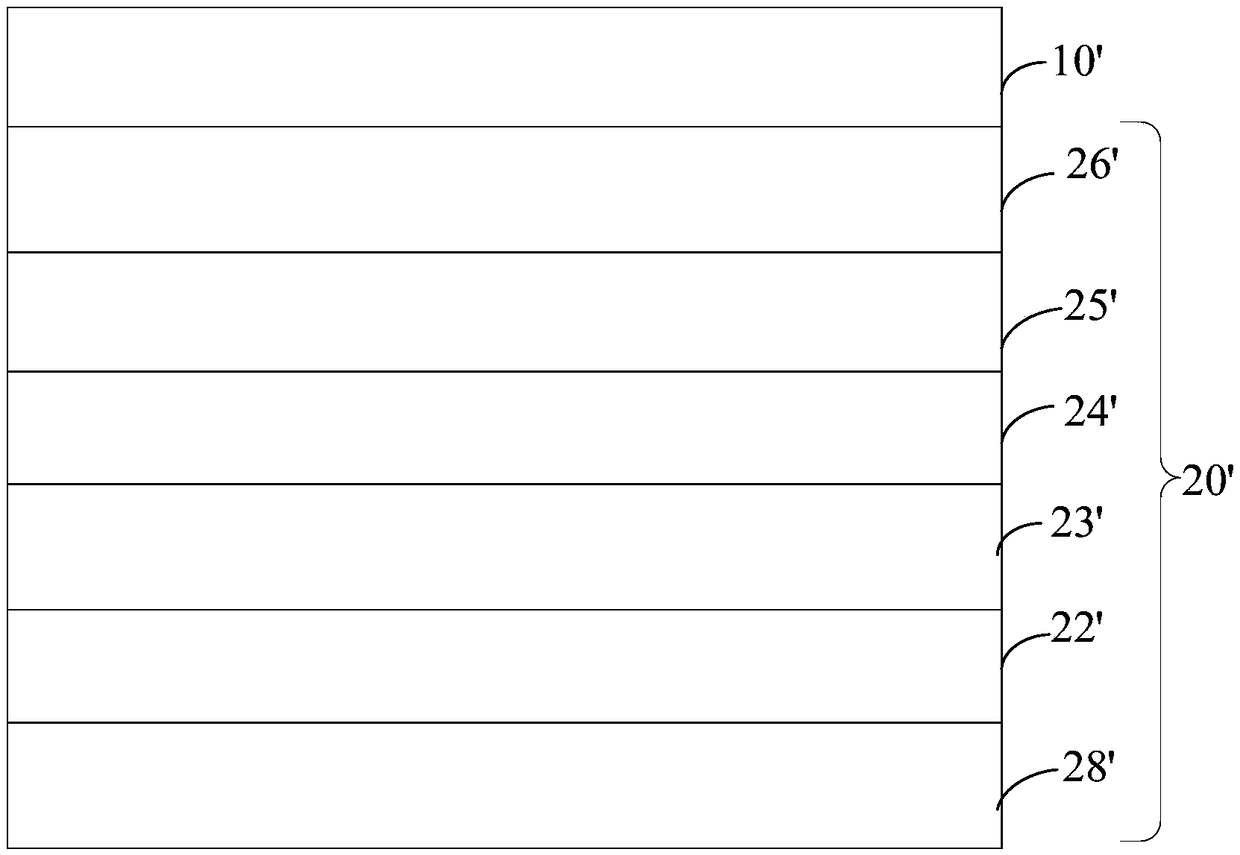

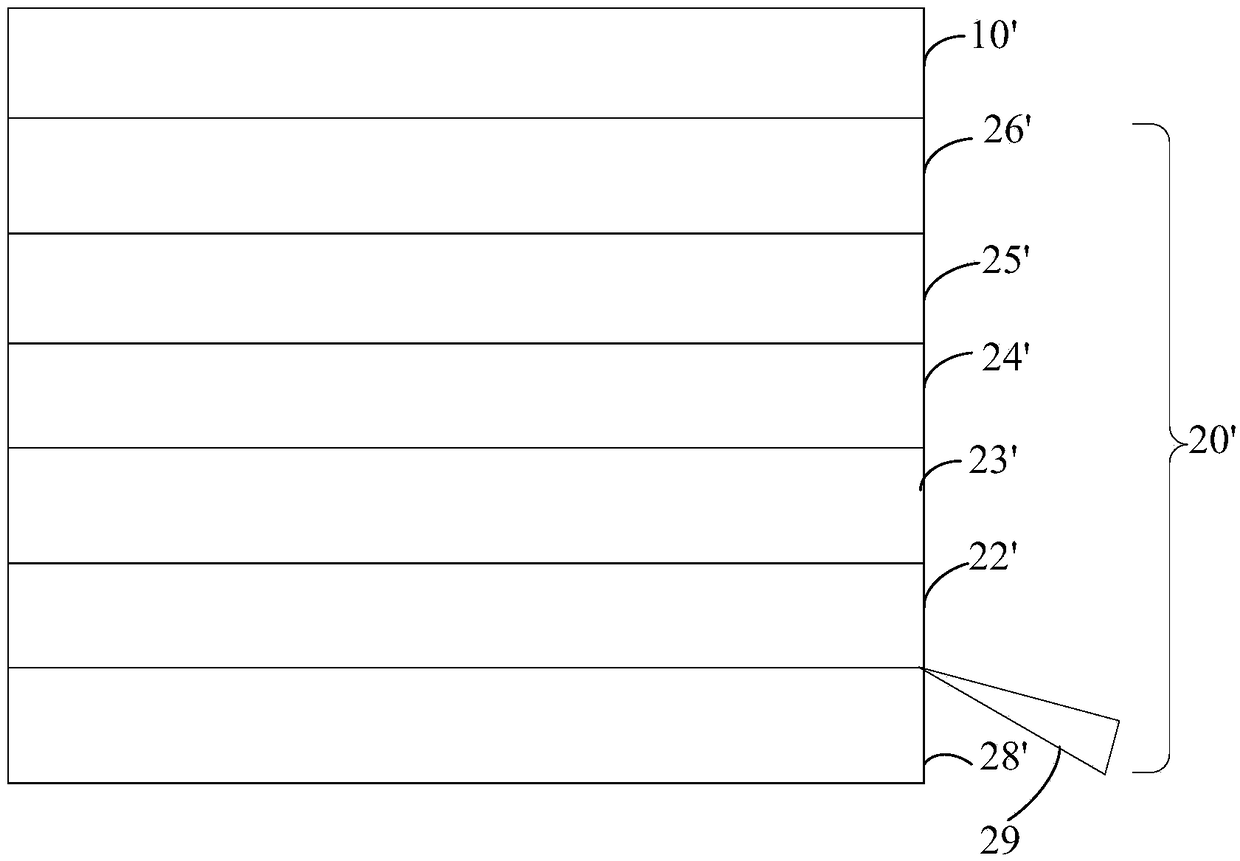

[0049] Please refer to the drawings in the accompanying drawings, wherein like reference numerals refer to like components. The following structural drawings and description of the embodiments are based on illustrated specific embodiments of the invention. It should be understood that the specific embodiments described here are only used to explain the present invention, and should not be construed as limiting other specific embodiments of the present invention that are not described in detail here.

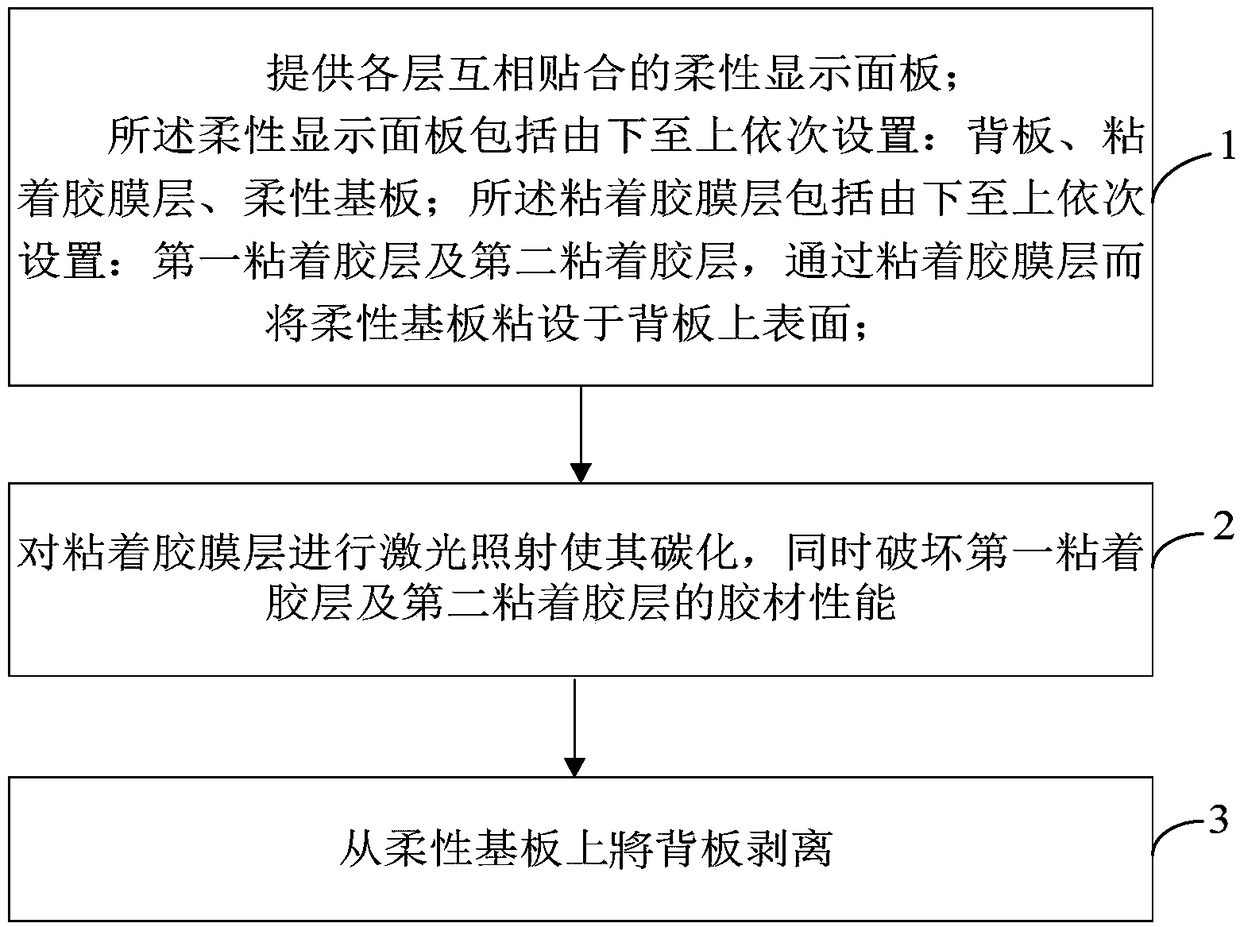

[0050] image 3 It is a flowchart of an embodiment of the peeling method of the flexible substrate of the present invention; Figure 4-5 It is a schematic diagram of step 2 of the peeling method of the present invention, which is to irradiate the adhesive film layer with laser to make it carbonized, and to separate and rework the backplane and the flexible substrate.

[0051] see image 3 , in a preferred embodiment, the stripping method of flexible substrate of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com