Intelligent plant factory

A factory and plant technology, applied in the field of intelligent plant factories, can solve the problems of insufficient utilization of resources, insufficient comprehensive and accurate adjustment of temperature, humidity and carbon dioxide concentration, poor consistency of temperature, humidity and carbon dioxide concentration, etc., to achieve precise control and improve Stability, the effect of improving continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

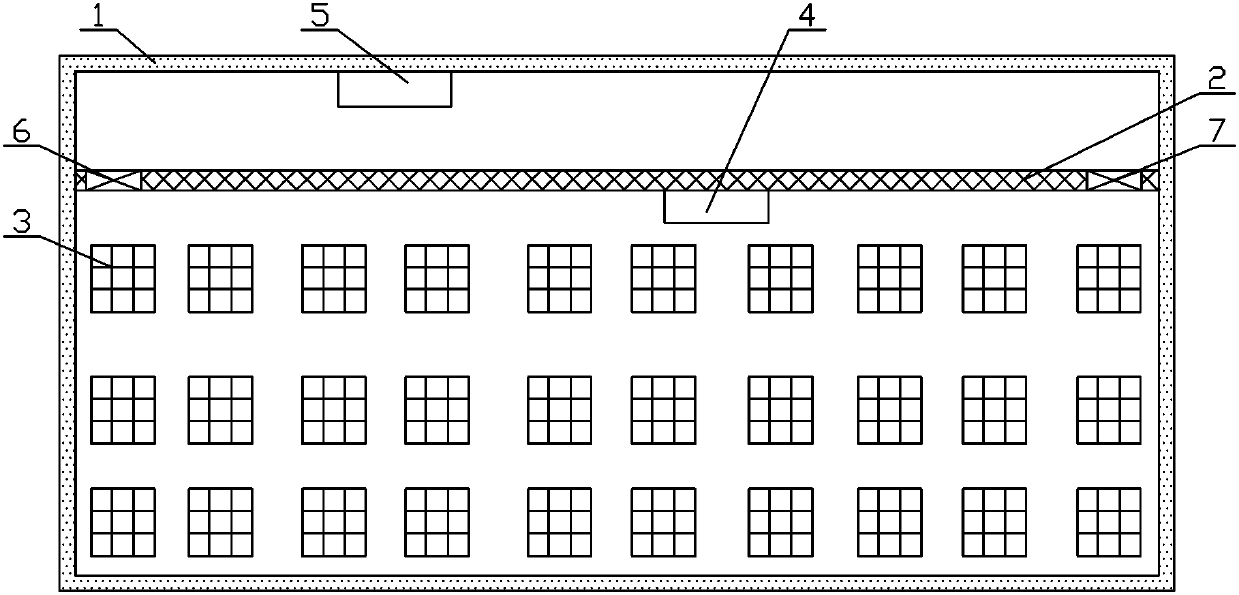

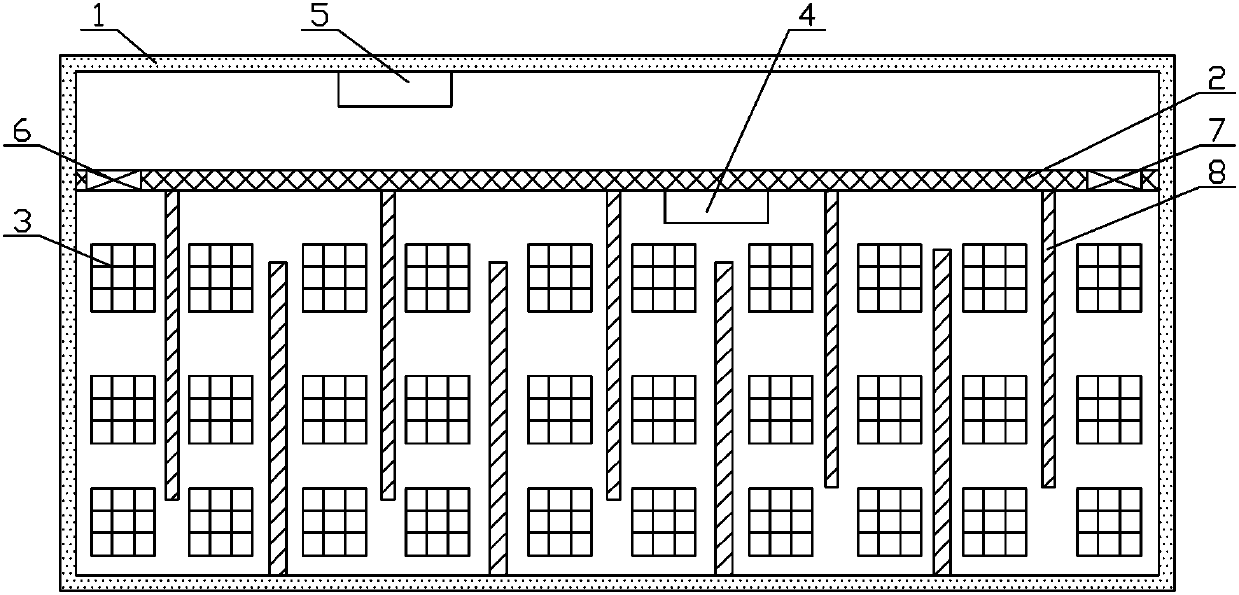

[0032] Such as figure 1 As shown, an intelligent plant factory includes a box body 1 and a monitoring system, the box body 1 is divided into a planting area and a regulating area by a first partition 2, and the planting area is provided with a seedling tray 3 and a sensing device 4. The adjustment area is provided with an adjustment device 5, and the first partition 2 is provided with a first air outlet for connecting the planting area and the adjustment area, and a first air inlet for connecting the planting area and the adjustment area , the first exhaust fan 6 for sending the air in the conditioning area to the planting area is installed in the first air outlet and / or the first air inlet for sending the air in the planting area to the conditioning area is installed in the first air outlet A suction fan 7 , the monitoring system is connected to the sensing device 4 , the regulating device 5 , the first exhaust fan 6 and the first suction fan 7 respectively.

[0033] In this...

Embodiment 2

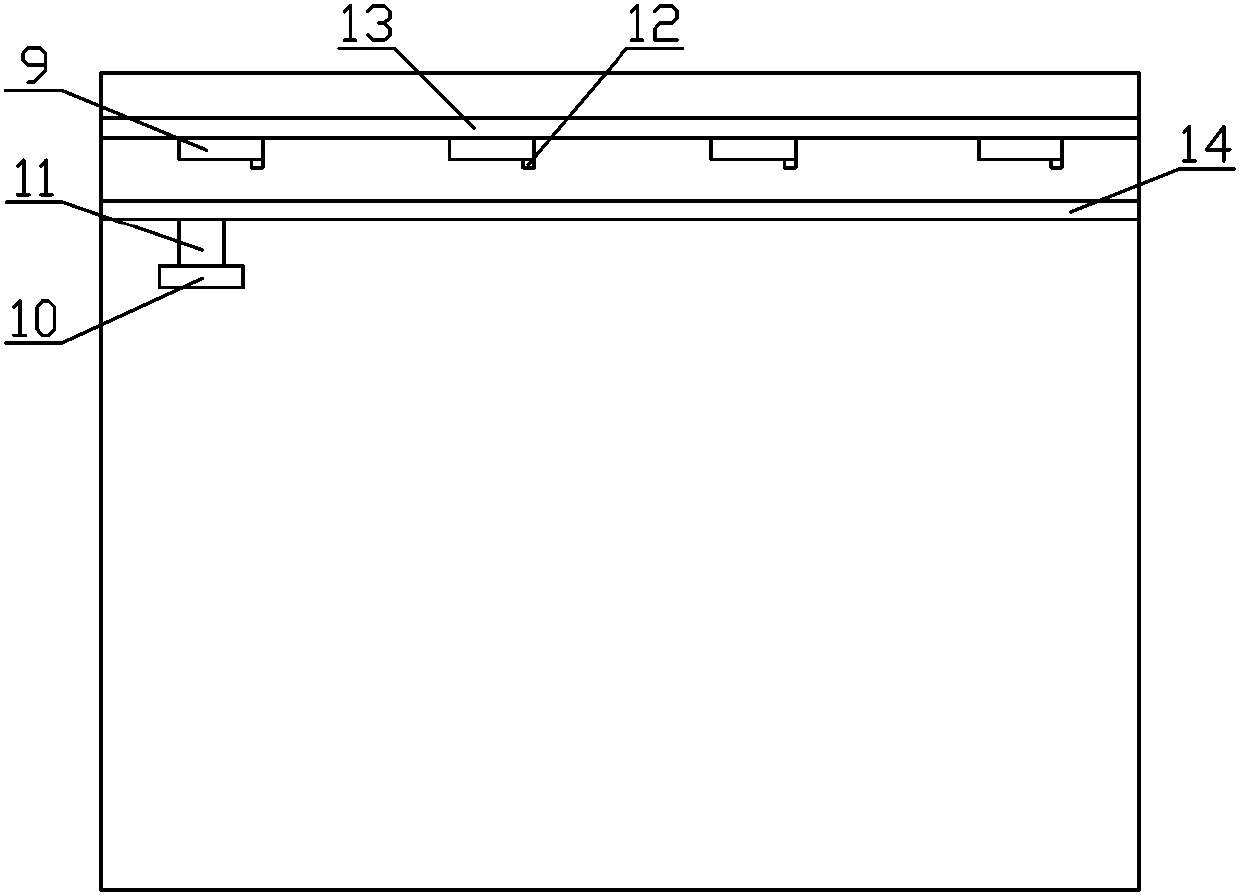

[0045] The technical solution of this embodiment is to further include on the basis of the technical solution of the first embodiment: image 3 As shown, a fixed light source 9, a mobile light source 10, a light source driving device 11, a light source detection device 12 for detecting whether the light source is faulty, a first mounting frame 13, and a second mounting frame 14 are also arranged in the box body 1. The fixed light source 9 is mounted on the first mounting frame 13, the light source driving device 11 is slidably mounted on the second mounting frame 14, the moving light source 10 is mounted on the light source driving device 11, the fixed light source 9, the moving light source 10. Both the light source drive device 11 and the light source detection device 12 are communicatively connected to the monitoring system.

[0046] In this embodiment, the light source detection device 12 detects whether the corresponding light source is faulty, and sends the detection res...

Embodiment 3

[0052] The technical solution of this embodiment is to further include on the basis of the technical solution of the first embodiment: Figure 5 As shown, the intelligent plant factory also includes a liquid distribution system, the liquid distribution system includes a raw material storage device 19, a stirring device 20 and a liquid distribution tank 21, and the raw material storage device 19 is located above the liquid distribution tank 21 , the bottom of the raw material storage device 19 is provided with a raw material guide structure 22, and the bottom of the raw material guide structure 22 is provided with a discharge port, and the discharge port is connected to the liquid distribution pool 21 through the raw material pipe 23, and the raw material pipe 23 is provided with a raw material control valve 24, the stirring device 20 is set at the bottom of the liquid distribution tank 21, and the top of the liquid distribution tank 21 is provided with a water source pipe 25, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com