Peak-hour laying hen feed production equipment and technique thereof

A technology for laying hen feed and production equipment, which is applied in feed, animal feed, animal feed and other directions, can solve the problems of insufficient feed absorption rate, increased heat, and chickens are easy to dry fire, etc., to achieve novel structure and more egg production. , the effect of high hatching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

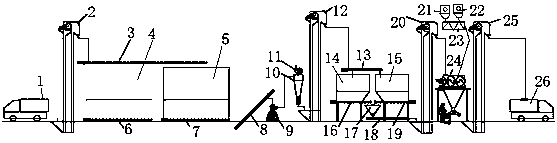

[0023] Embodiment 1, with reference to the accompanying drawings, the first raw material hoist 2 sends the raw materials of the transport vehicle 1, including corn, soybean meal, and wheat bran, to the raw material distribution conveyor belt 3, and the raw materials are respectively sent to the first raw material bin 4 through the distribution conveyor belt 3 1. After the second raw material warehouse 5, it is sent to the feeding auger 8 through the first discharge auger 6 and the second discharge auger 7, and then sent to the pulverizer 9, and then sent to the brake auger 10 after being pulverized by the pulverizer 9. , there is a blower 11 on the top surface of the brake dragon 10, and the crushed raw material powder enters the rough feed distribution bin auger 13 through the rough feed hoist 12, and the rough feed distribution bin auger 13 enters the first rough feed bin 14 and the second rough feed bin 13. The warehouse 15 enters the weighing hopper 17 through the first bat...

Embodiment 2

[0024] Embodiment 2, with reference to Example 1, the operating steps of the present invention are: according to step 1, the feed composition mass parts are: 80 ~ 90 mass parts of corn, 60 ~ 80 mass parts of soybean meal, 10 ~ 20 mass parts of soybean oil, 30 ~ 30 mass parts of bran 50 parts by mass, 50-70 parts by mass of stone powder, 10-20 parts by mass of red vine, 10-20 parts by mass of corn stalk, 10-20 parts by mass of peanut vine, 45-10 parts by mass of probiotics, 5-10 parts by mass of anti-inflammatory medicinal materials share. The anti-inflammatory medicinal materials are mainly 1-2 parts by mass of Poria cocos, Cortex Phellodendri, Hawthorn and Coptis chinensis. Step 2, 80 parts by mass of corn, 60 parts by mass of soybean meal, 20 parts by mass of soybean oil, 50 parts by mass of bran, and 70 parts by mass of stone powder are distributed from the first raw material elevator 2 to the distribution conveyor belt 3 and input into the first raw material bin 4, The se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com