Lifting filter structure

A filter structure, lifting technology, applied in the field of daily necessities, can solve the problems of difficulty in realizing the tea-brewing function, cumbersomeness, inability to realize the tea-water separation function, etc., and achieve the effects of simple shape, improved space utilization, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

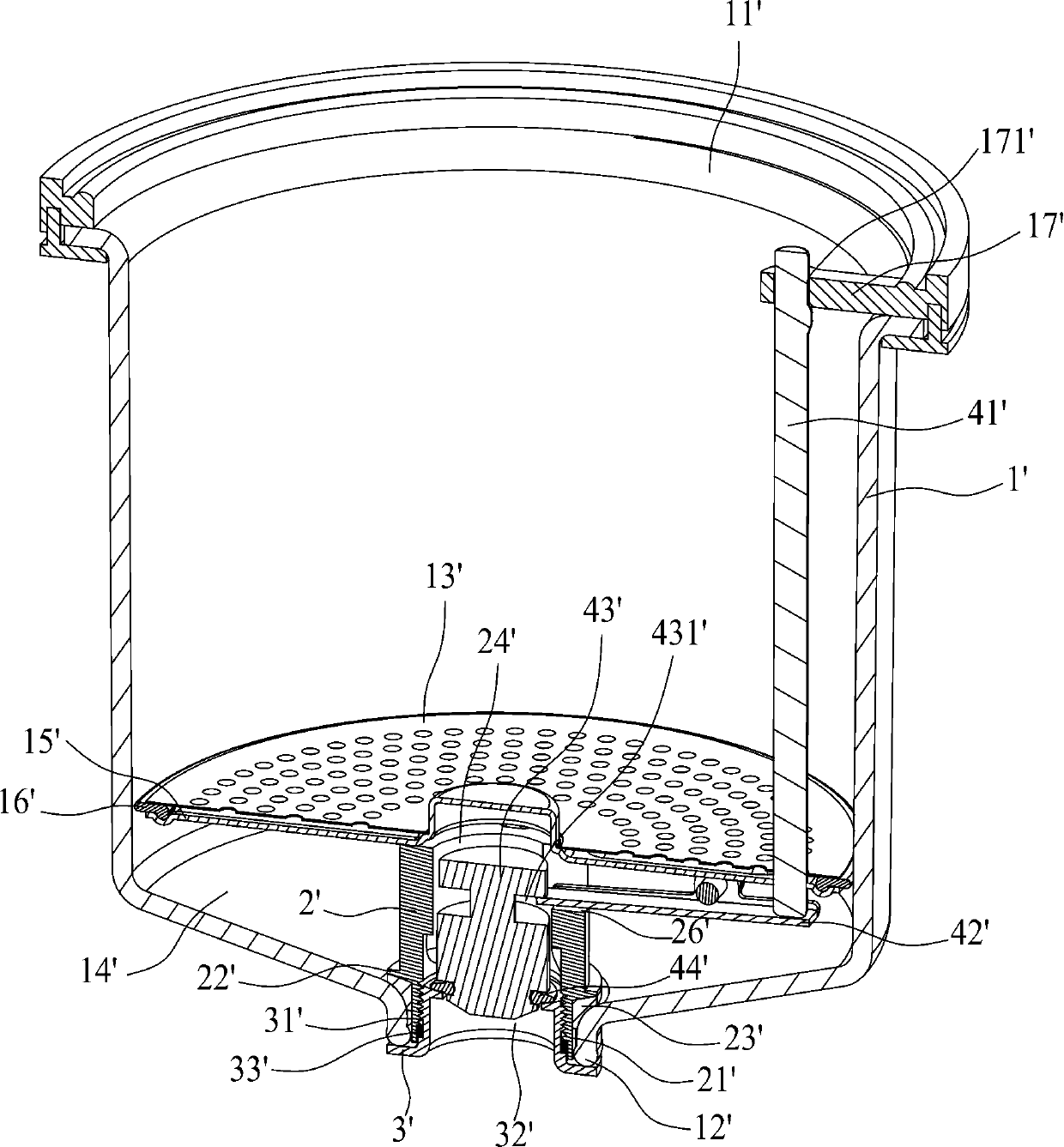

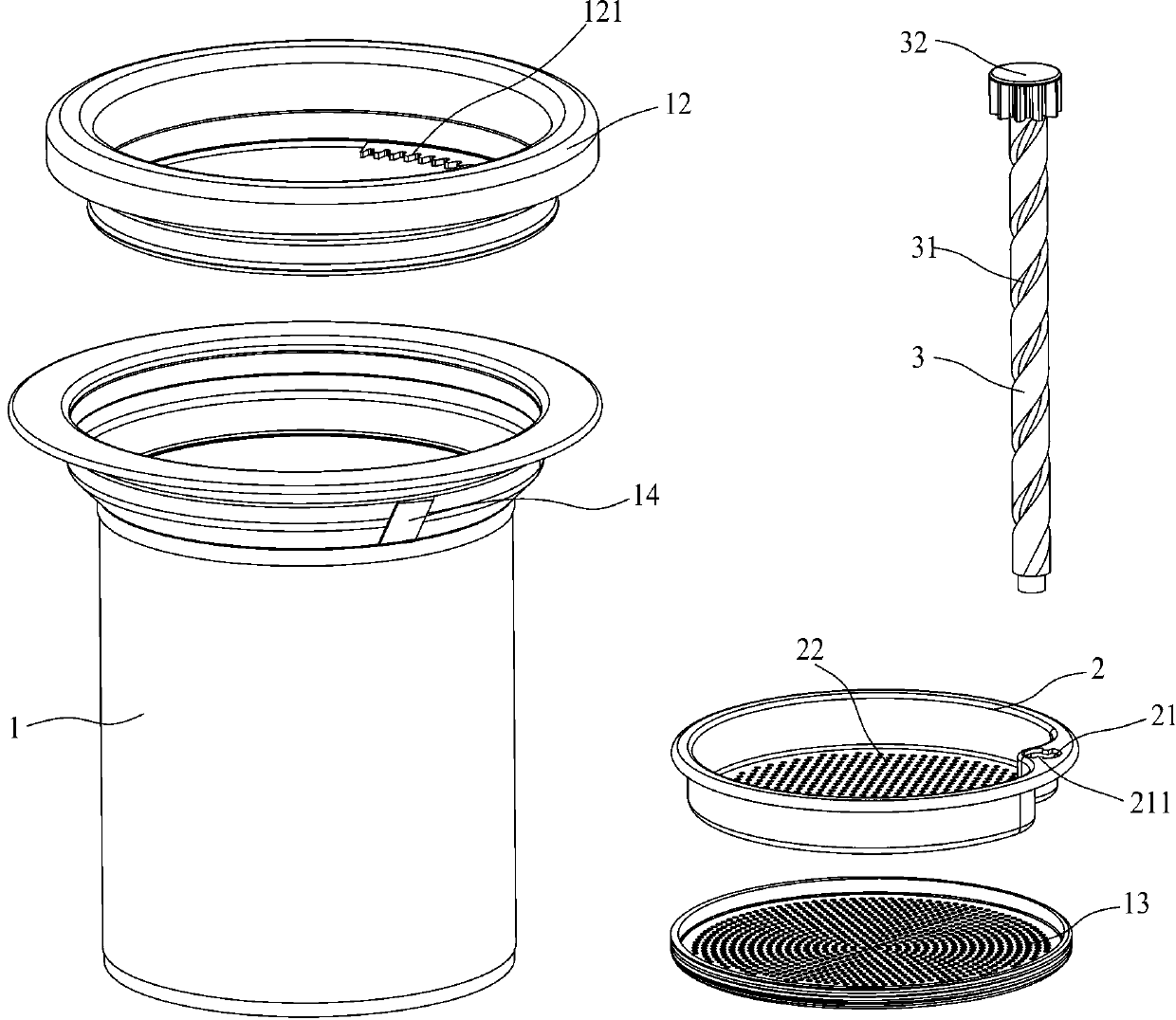

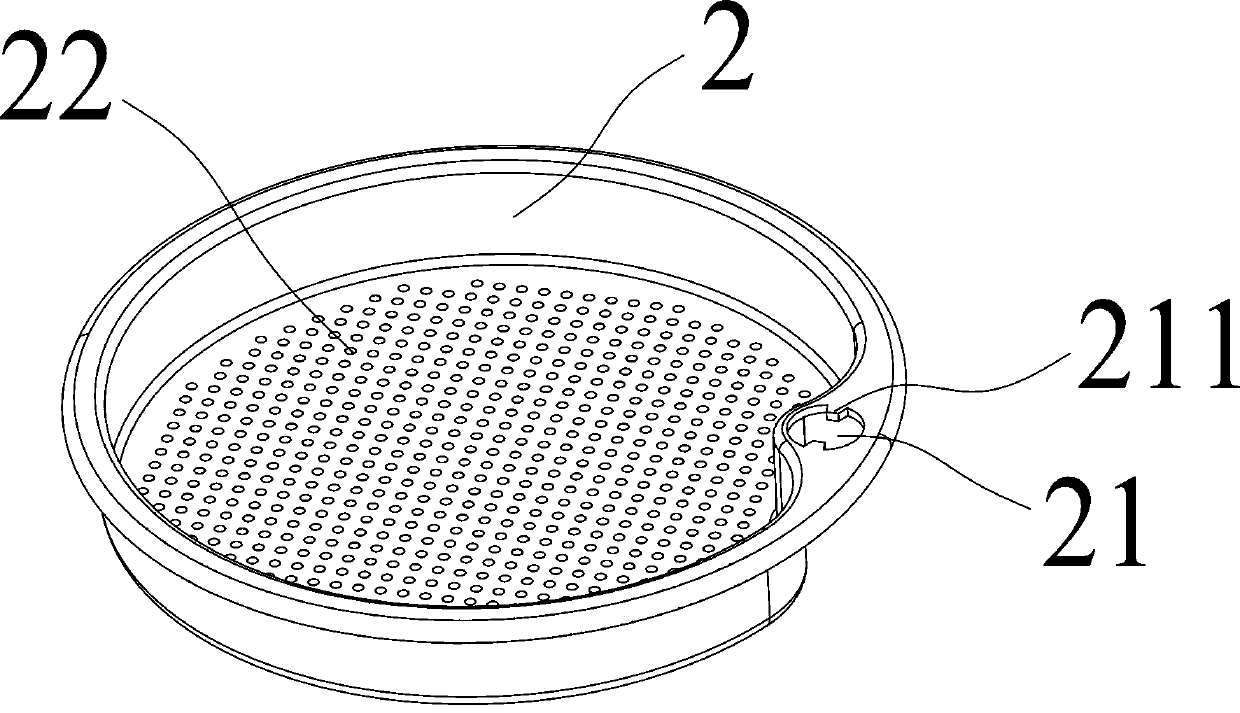

[0025] Such as Figure 2 to Figure 4 As shown, a lifting filter structure described in this embodiment includes a receiving part 1, a movable frame 2 and a guide post 3; the receiving part 1 is a hollow cylindrical structure, and the receiving part 1 is provided with a guide post The fixed hole 11, the guide post 3 is assembled in the receiving part 1 and rotatably inserted in the guide post fixing hole 11, and the surface is provided with a spiral guide groove 31, and the movable frame 2 is movably assembled in the receiving part 1 Inside, the movable frame 2 is provided with a guide post hole 21 that matches the guide post 3 and is movably sleeved on the guide post 3, and the guide post hole 21 is provided with a bump 211 that matches the guide post spiral guide groove 31 , so that the movable frame 2 can reciprocate in the receiving part 1 with the rotation of the guide post 3 .

[0026] There are at least two guide post fixing holes 11 , which are located at the upper end...

Embodiment 2

[0035] A lifting filter structure of the present invention is the same as embodiment 1 except the following technical features, as Figure 5 As shown, the outer side of the receiving part 1 is provided with a card platform 15, which is similar to the elastic part in embodiment 1, so that the receiving part can be detachably fixed on the outer cup (not shown in the figure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com