Polyester synthesis reactor

A synthesis reaction and polyester technology, applied in mixers, chemical/physical/physicochemical fixed reactors, cleaning hollow objects, etc., can solve the problems of structural dispersion, failure to achieve integrity, and improvement of mixing efficiency. Achieve the effect of accelerating mixing and improving stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

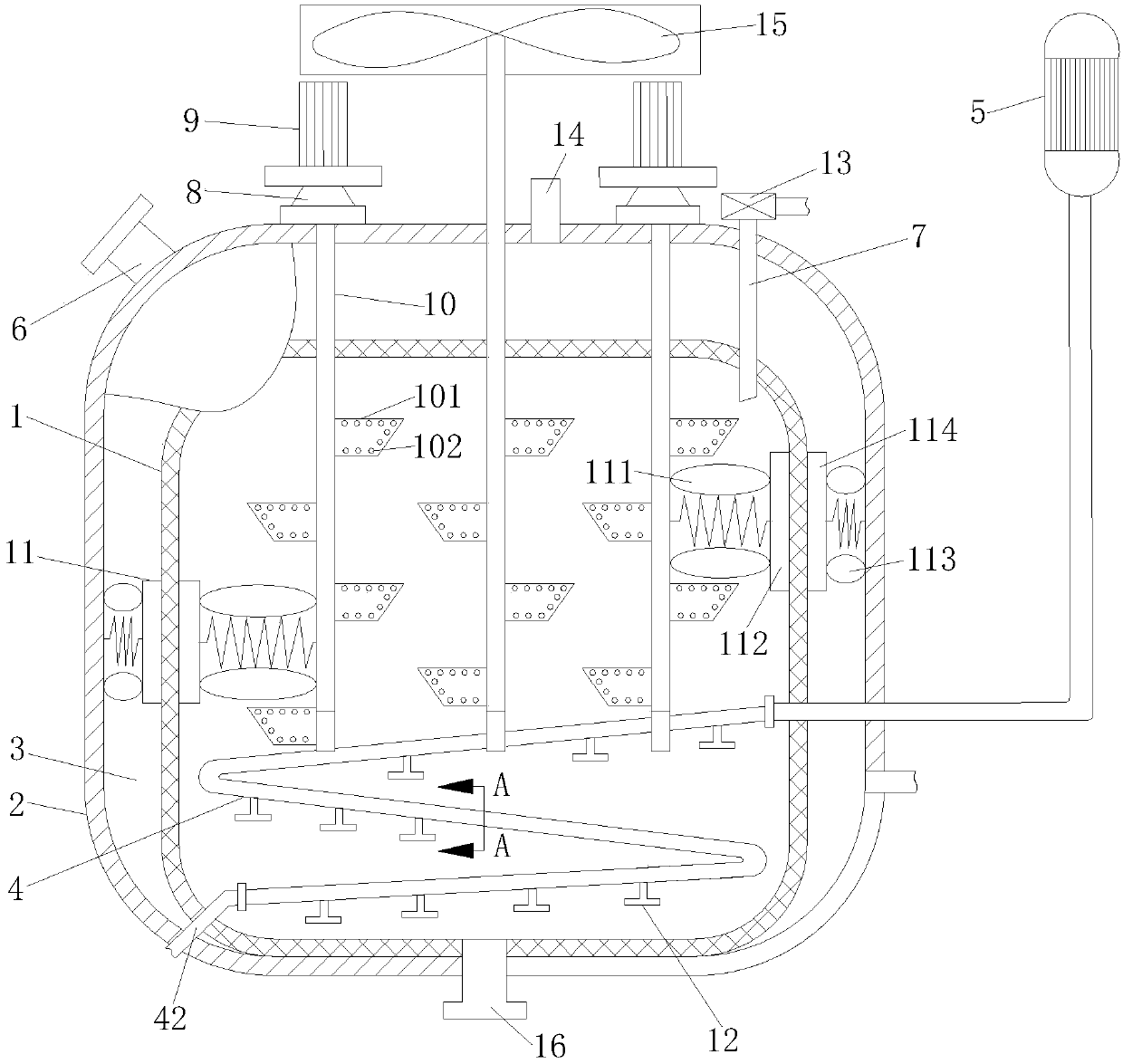

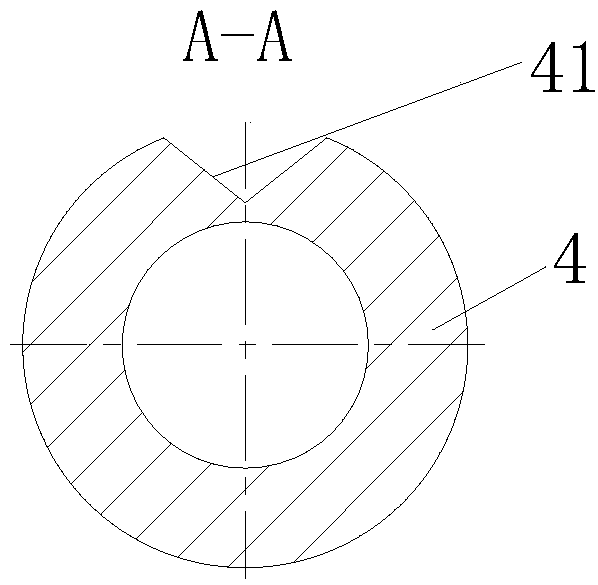

[0022] Such as Figure 1 to Figure 2As shown, a polyester synthesis reaction kettle according to the present invention includes a kettle body, the kettle body includes an inner wall 1 and an outer wall 2, the inner wall 1 is made of elastic rubber, and the inner wall The bottom of 1 is fixedly connected with the bottom of the outer wall 2, and a jacket layer 3 is formed between the inner wall 1 and the outer wall 2, and a high-temperature heat-conducting agent is conveyed in the jacket layer 3, and the inner wall 1 A cooling coil 4 is arranged inside, and the cooling coil 4 is arranged in a circular coil in the inner wall 1. The upper part of the kettle body is provided with a feed pipe 6 and an exhaust pipe 7, and the bottom of the kettle body is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com