A kind of preparation method and application of vanadyl phosphate catalyst

A vanadyl phosphate catalyst, vanadium source technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry and other directions, can solve problems such as unstable performance and electronic defects, and achieve low cost, simple operation, and simplified preparation. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of vanadyl phosphate catalyst, it comprises the following steps:

[0027] (1) Vanadium source, heteropolyacid ionic liquid, benzyl alcohol and C 3 ~C 8 The monohydric alcohol is mixed, obtains the mixture, reacts, wherein, the anion general formula of described heteropolyacid ionic liquid is [XM 12 o 40 ] n- or [Y 2 N 18 o 62 ] n- , X is the element Si or P, M is at least one of the elements W, Mo, V and Nb, Y is the element P, and N is at least one of the elements W, Mo and V, and the heteropolyacid ionic liquid The cation is at least one of quaternary ammonium cations and derivatives thereof, alkyl substituent imidazolium cations and pyrrole cations and derivatives thereof;

[0028] (2) Mix the reaction product obtained in step (1) with the phosphorus source, raise the temperature to 100°C to 200°C, and continue the reaction to obtain the vanadyl phosphate precursor;

[0029] (3) Roasting to obtain the vanad...

Embodiment 1

[0053] Preparation of vanadyl phosphate catalyst:

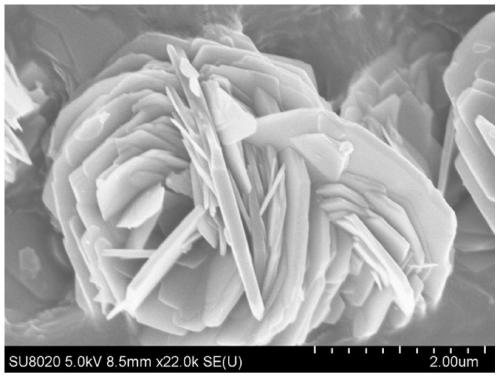

[0054] Weigh 4.54g V 2 o 5 (0.25mol) was placed in a 250mL three-necked flask, and 0.55g [TBA] was added 3 PMo 12 o 40 , 40mL of isobutanol and 10mL of benzyl alcohol, mechanically stirred and mixed evenly, refluxed at 135°C for 3h and then cooled to 70°C. Slowly add 3.61 mL of 85% H 3 PO 4 , and continued to reflux for 16 hours at a temperature of 135° C. The precipitate was filtered, washed with absolute ethanol, and dried in air at 80° C. for 24 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder was pressed into tablets under a pressure of 15 MPa, crushed, and 20-40 mesh catalyst particles were sieved. Afterwards, the catalyst particles were activated in situ in an atmosphere of n-butane / oxygen / nitrogen reaction gas with a volume ratio of 1.5:17:81.5 from room temperature to 430°C at a rate of 2°C / min for 12 hours to obtain a vanadyl phosphate catalyst.

[0055] Detection:

[0056...

Embodiment 2

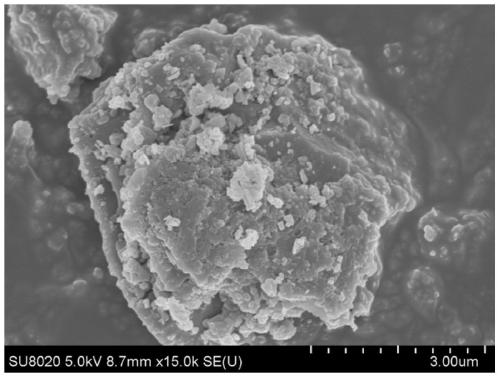

[0059] Weigh 4.54g V 2 o 5 (0.25mol) was placed in a 250mL three-necked flask, and 0.51g [TBA] was added 4 PMo 11 VO 40 , 40mL of isobutanol and 10mL of benzyl alcohol, mechanically stirred and mixed evenly, refluxed at 135°C for 3h and then cooled to 70°C. Slowly add 3.61 mL of 85% H 3 PO 4 , and continued to reflux for 16 hours at a temperature of 135° C. The precipitate was filtered, washed with absolute ethanol, and dried in air at 80° C. for 24 hours to obtain a catalyst precursor powder. The obtained catalyst precursor powder was pressed into tablets under a pressure of 15 MPa, crushed, and 20-40 mesh catalyst particles were sieved. Afterwards, the catalyst particles were activated in situ in an atmosphere of n-butane / oxygen / nitrogen reaction gas with a volume ratio of 1.5:17:81.5 from room temperature to 430°C at a rate of 2°C / min for 12 hours to obtain a vanadyl phosphate catalyst.

[0060] Detection:

[0061] Weigh 2.0g of the vanadyl phosphate catalyst and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com