Robot grinding consumable automatic replacing system applying infrared temperature measurement

An infrared temperature measurement and automatic replacement technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve problems such as instability, shaking, thread tooth collapse and joint, and reduce labor intensity , prevent device displacement, prevent the effect of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

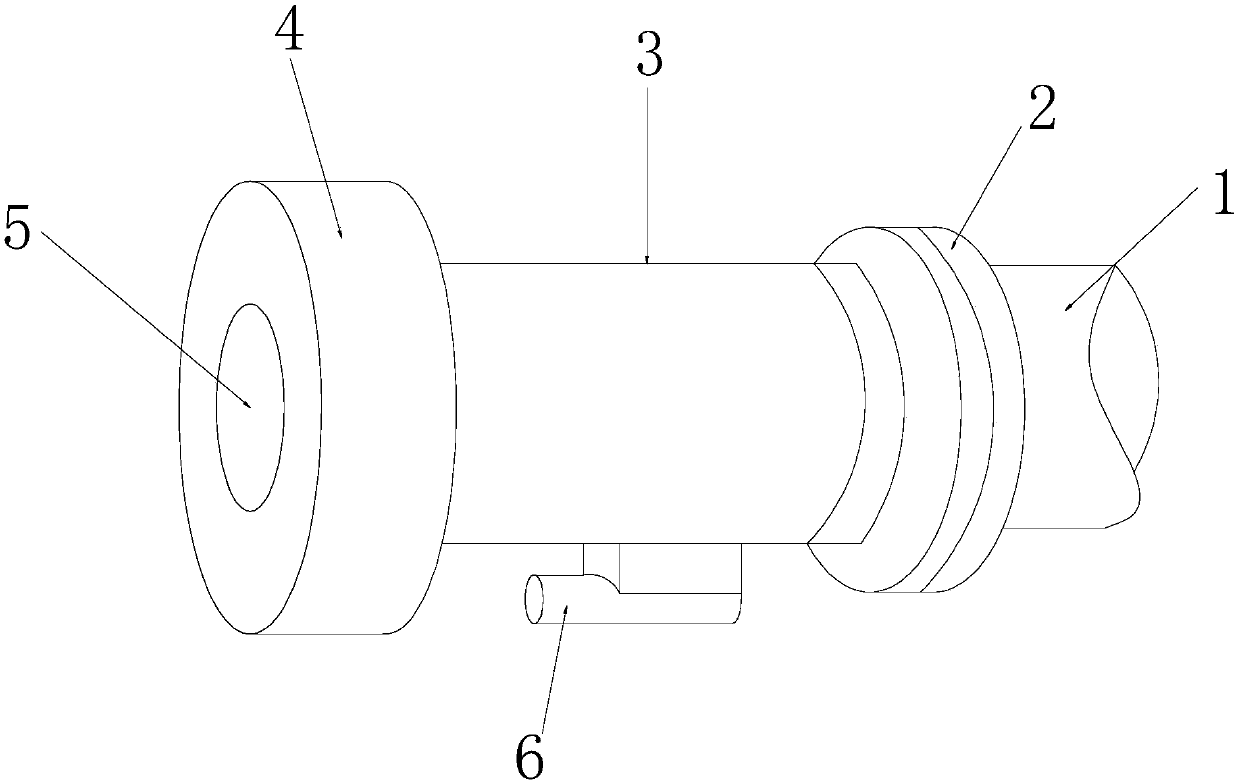

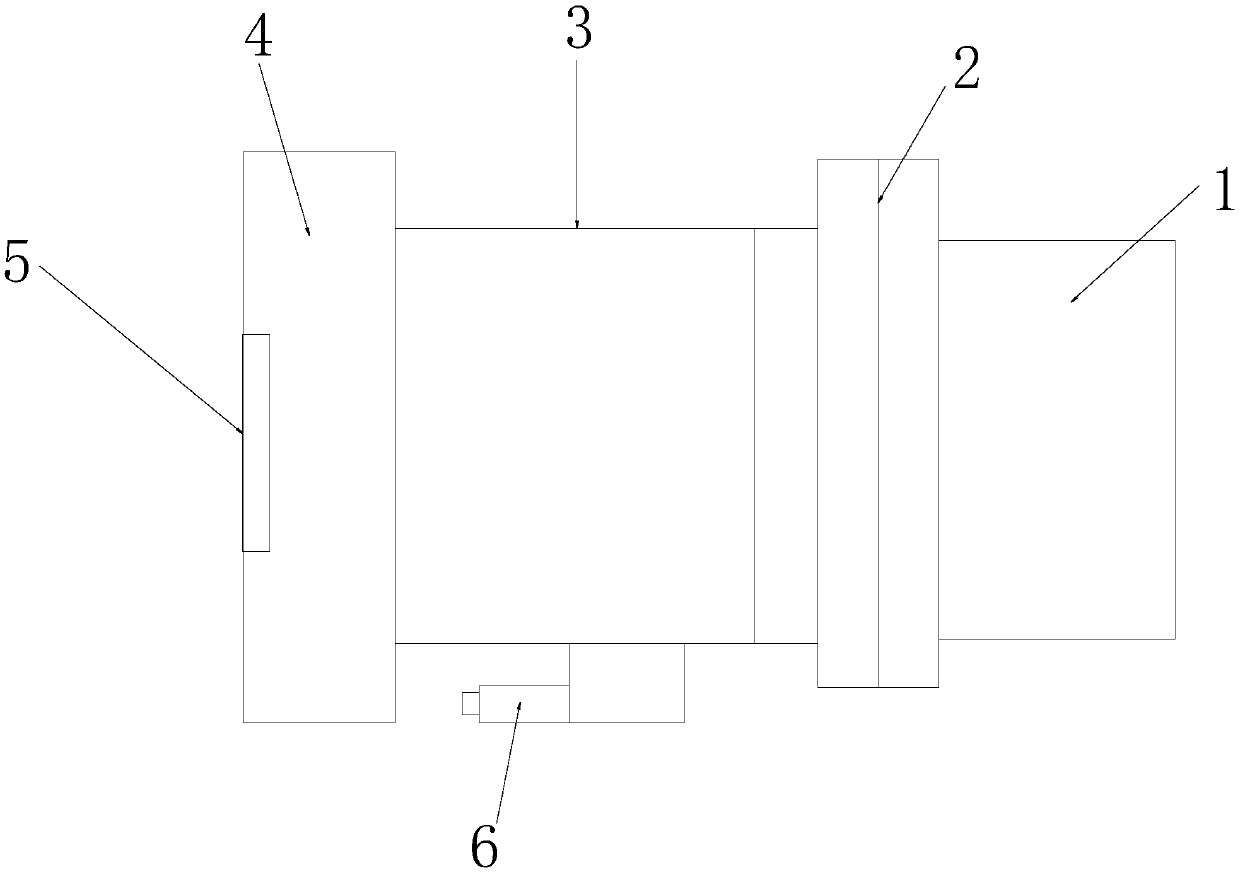

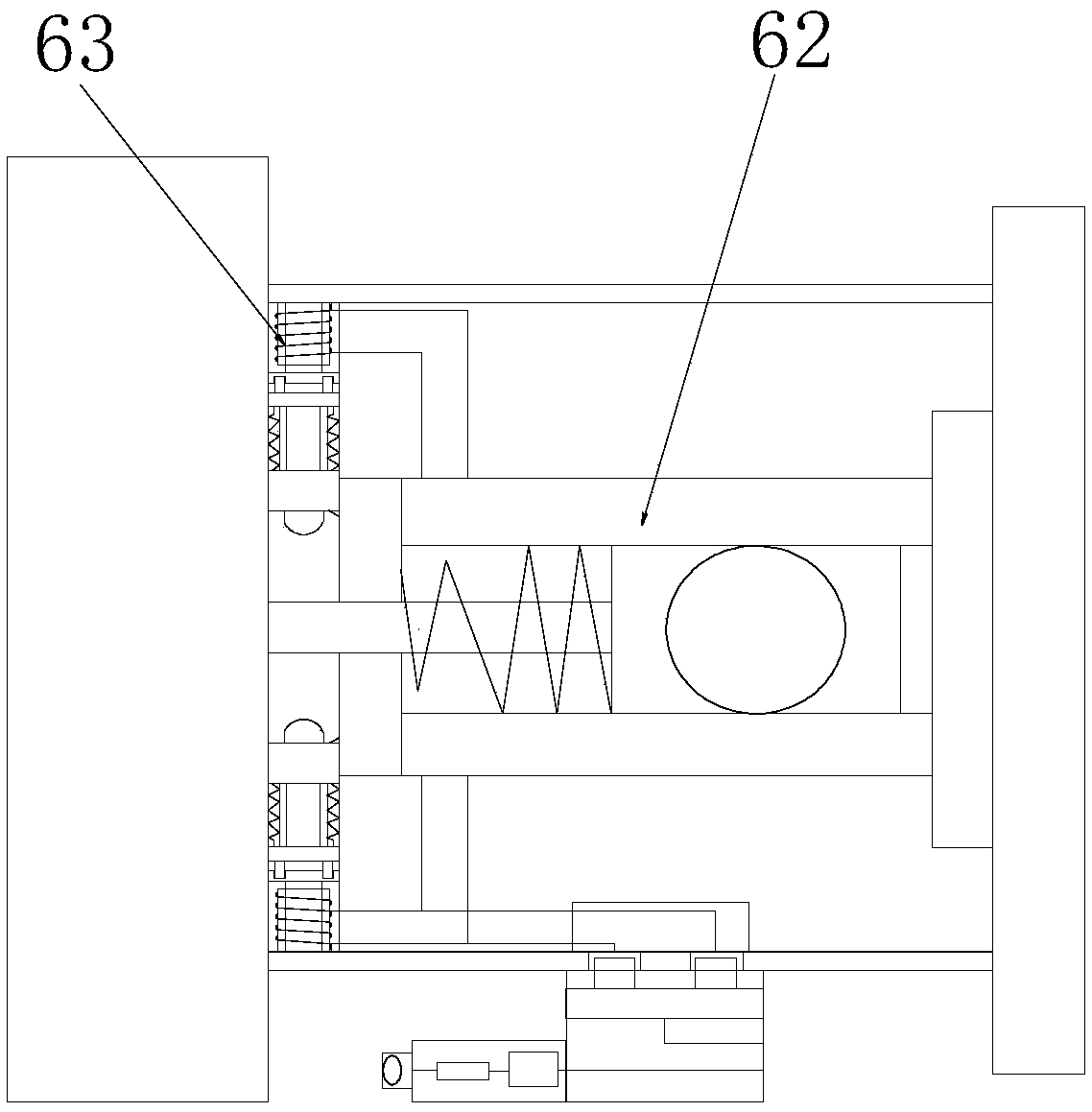

[0023] see figure 1 and figure 2 , the present invention provides an automatic replacement system for robot grinding consumables through infrared temperature measurement, the structure of which includes: a spindle rod 1, an engaging frame 2, a device housing 3, a friction wheel 4, a through hole 5, and an intelligent replacement device 6, the device The housing 3 is located on the right end surface of the joint frame 2, and the two adopt a clearance fit. The spindle rod 1 and the joint frame 2 are perpendicular to each other and are fixedly connected with the joint frame 2 to form an integrated structure. The intelligent replacement device 6 is located in the device housing. The inside of 3 is movably connected with the device housing 3 at the same time. The friction wheel 4 is located on the left end surface of the intelligent replacement device 6 and is snap-connected with the intelligent replacement device 6. The through hole 5 is located at the center of the left end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com