A temperature sensing material insulation box

A technology for sensing materials and incubators, applied in the field of electronic ceramics, can solve the problems of inaccurate control of a constant temperature environment, insensitivity to changes in the temperature of the incubator, and inability to accurately control the temperature of the incubator. Temperature-sensitive, high-performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

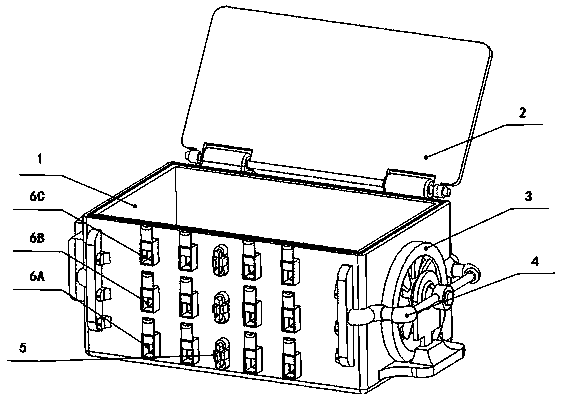

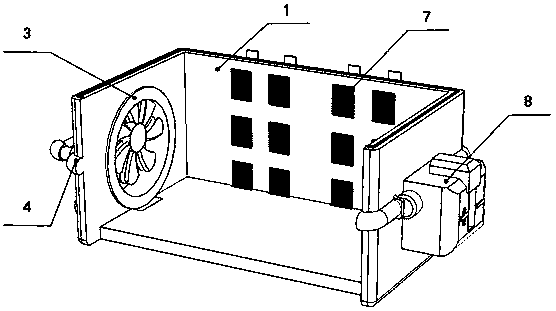

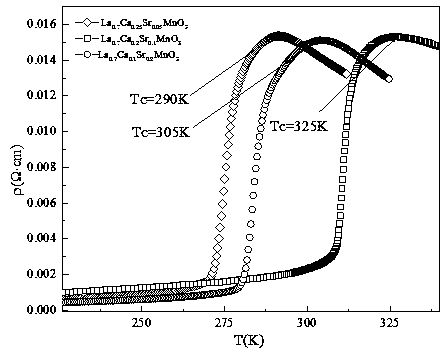

[0022] like figure 1 and 2 As shown, the temperature-sensing material insulation box includes box body 1, box cover 2, hot air blower 3, through pipe 4, switch 5, block box I6A, block box II6B, block box III6C, temperature sensing net 7, Power supply equipment box 8, temperature sensing material La 0.7 Ca 0.25 Sr 0.05 MnO 3 , La 0.7 Ca 0.2 Sr 0.1 MnO 3 , La 0.7 Ca 0.1 Sr 0.2 MnO 3Polycrystalline ceramic blocks, and wires; the top of the box body 1 is provided with a box cover 2 that is opened and closed relative to the box body 1, and one side of the box body 1 is provided with a hot air blower 3, and the hot air outlet of the hot air blower 3 is connected to the box body 1 The inside is connected, the other side of the box body 1 is provided with a power supply equipment box 8, and the front surface of the hot air blower 3 is provided with a three-layer block box. The three-layer block box is uniformly equipped with several block boxes I6A, block Box II6B and bl...

Embodiment 2

[0030] like figure 1 and 2 As shown, the temperature-sensing material insulation box includes box body 1, box cover 2, hot air blower 3, through pipe 4, switch 5, block box I6A, block box II6B, block box III6C, temperature sensing net 7, Power supply equipment box 8, temperature sensing material La 0.7 Ca 0.25 Sr 0.05 MnO 3 , La 0.7 Ca 0.2 Sr 0.1 MnO 3 , La 0.7 Ca 0.1 Sr 0.2 MnO 3 Polycrystalline ceramic blocks, and wires; the top of the box body 1 is provided with a box cover 2 that is opened and closed relative to the box body 1, and one side of the box body 1 is provided with a hot air blower 3, and the hot air outlet of the hot air blower 3 is connected to the box body 1 The inside is connected, the other side of the box body 1 is provided with a power supply equipment box 8, and the front surface of the hot air blower 3 is provided with a three-layer block box. The three-layer block box is uniformly equipped with several block boxes I6A, block Box II6B and b...

Embodiment 3

[0038] like figure 1 and 2 As shown, the temperature-sensing material insulation box includes box body 1, box cover 2, hot air blower 3, through pipe 4, switch 5, block box I6A, block box II6B, block box III6C, temperature sensing net 7, Power supply equipment box 8, temperature sensing material La 0.7 Ca 0.25 Sr 0.05 MnO 3 , La 0.7 Ca 0.2 Sr 0.1 MnO 3 , La 0.7 Ca 0.1 Sr 0.2 MnO 3 Polycrystalline ceramic blocks, and wires; the top of the box body 1 is provided with a box cover 2 that is opened and closed relative to the box body 1, and one side of the box body 1 is provided with a hot air blower 3, and the hot air outlet of the hot air blower 3 is connected to the box body 1 The inside is connected, the other side of the box body 1 is provided with a power supply equipment box 8, and the front surface of the hot air blower 3 is provided with a three-layer block box. The three-layer block box is uniformly equipped with several block boxes I6A, block Box II6B and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com