Lime kiln air inlet system

A technology of air intake system and lime kiln, which is applied in the field of iron and steel production, can solve the problems of increasing procurement costs and operating costs, increasing the operating power of combustion-supporting fans, and lime nodules, so as to reduce procurement costs and operating costs and avoid lime nodules , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

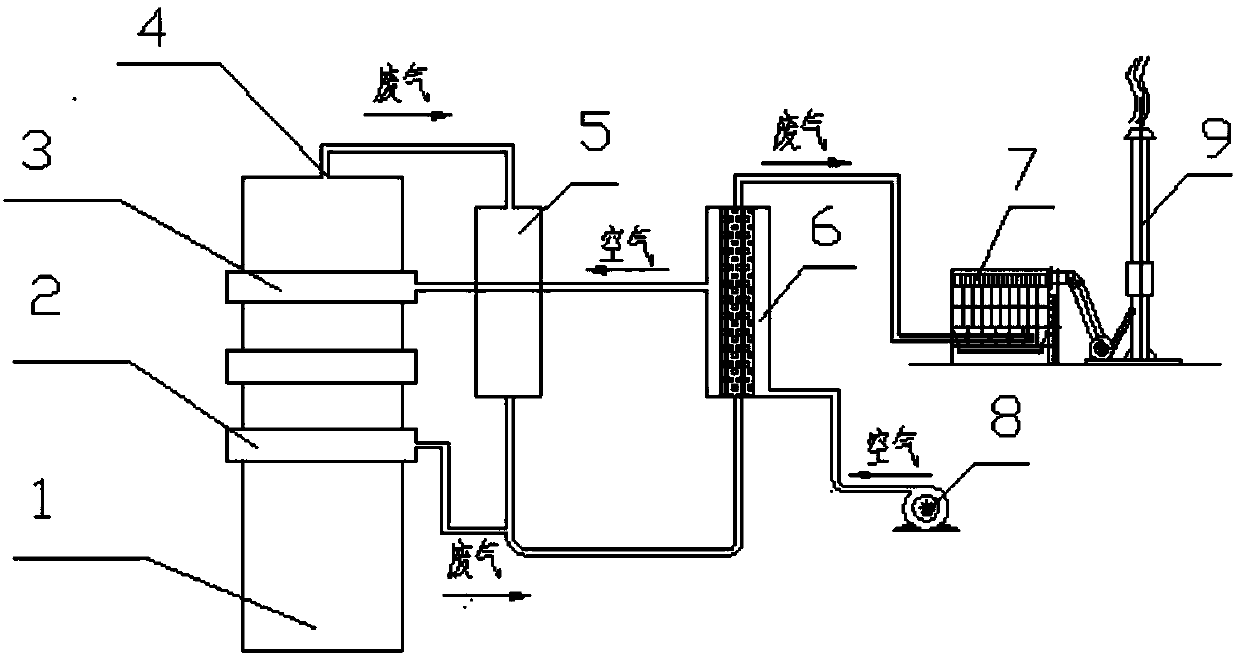

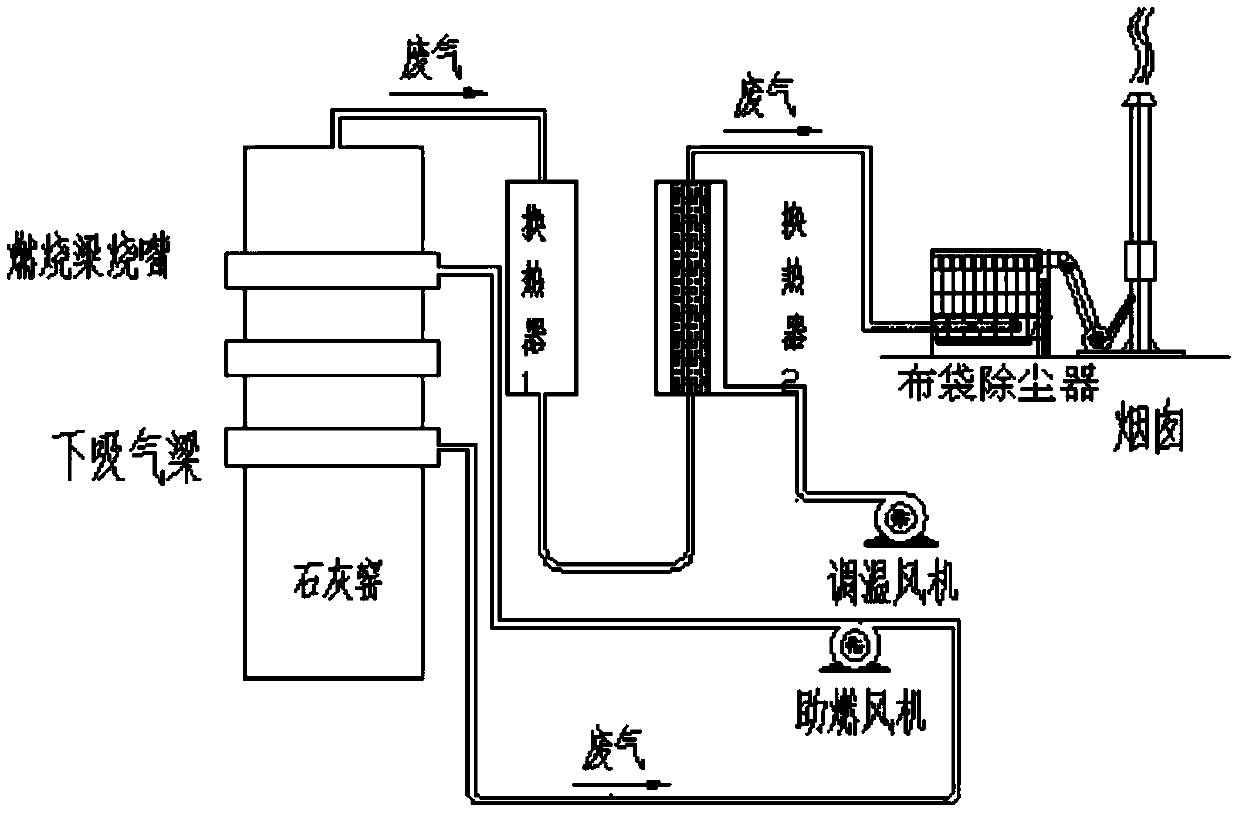

[0013] The lime kiln air intake system includes a lime kiln, an air intake device and a heat exchanger. The lime kiln includes a kiln body 1, a lower suction beam 2, a combustion beam 3 and a kiln body waste gas discharge port 4. The combustion beam is provided with There is a combustion beam burner, the lower suction beam is provided with a lower suction beam exhaust gas discharge port, and the air intake device includes a combustion-supporting fan 8, and the air introduced by the combustion-supporting fan passes through the heat exchanger, the lower suction beam exhaust gas and the kiln body The exhaust gas enters the combustion beam burner after heat exchange.

[0014] Further, the heat exchanger includes a first heat exchanger 5 and a second heat exchanger 6, the first heat exchanger is provided with a kiln body waste gas inlet and a kiln body waste gas outlet, and the second heat exchanger is provided with a total waste gas Inlet, total exhaust gas outlet, combustion air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com