A kind of asphalt for tunnel pavement and preparation method thereof

A kind of asphalt and pavement technology, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of asphalt's low-temperature crack resistance, influence, and the contribution of asphalt's high-temperature stability, so as to reduce the maintenance cycle and improve durability. non-toxic, excellent flame retardant and smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

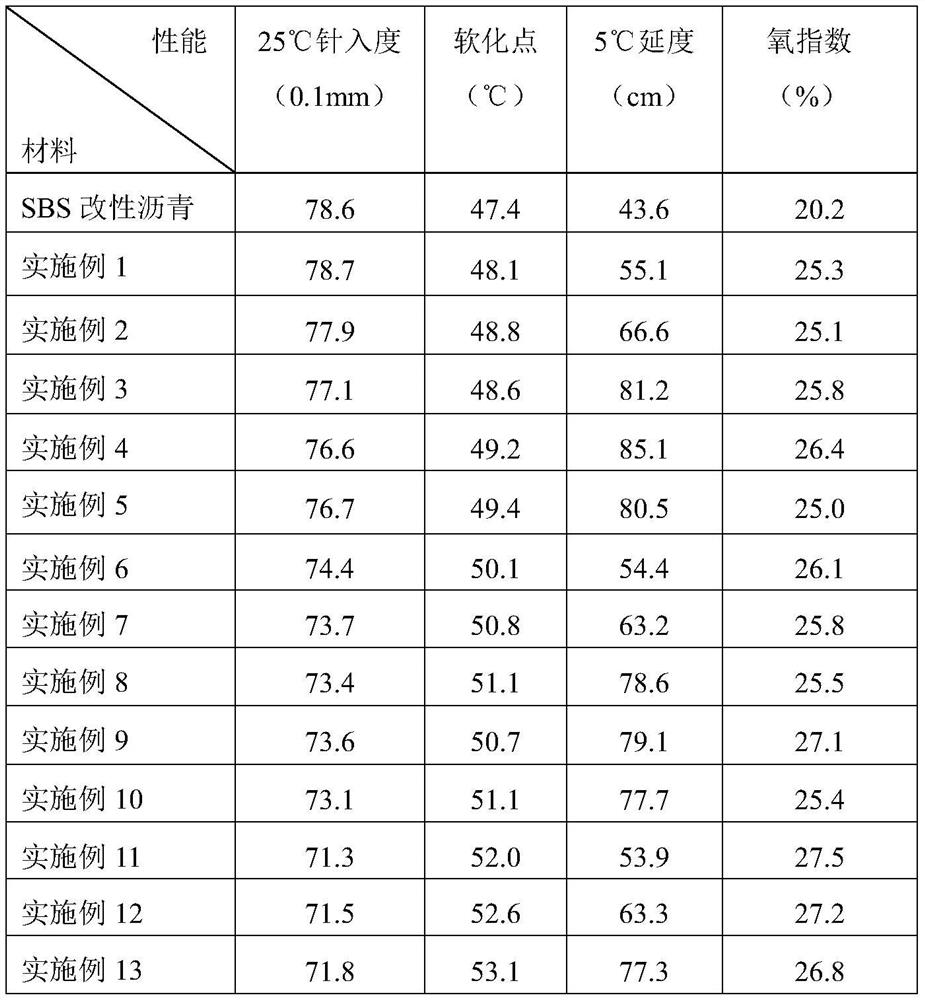

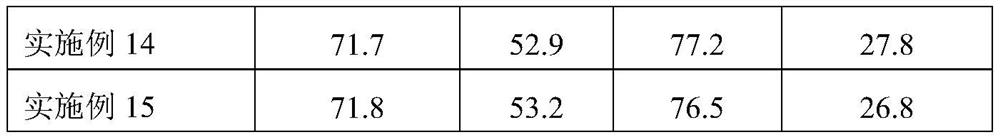

Examples

preparation example Construction

[0031] A preparation method for tunnel pavement asphalt, specifically comprising the following steps:

[0032] Step 1), first heating the base asphalt to a molten state, then sequentially adding organic rectorite and composite additives into the molten base asphalt and stirring evenly to obtain a mixture A;

[0033] Step 2), mixing polyurethane prepolymer and anti-aging agent to obtain mixture B, adding mixture B to mixture A and mixing uniformly to obtain mixture C;

[0034] Step 3), finally adding the flame retardant to the mixture C, and mixing evenly to obtain the required tunnel pavement asphalt.

[0035] Further, in step 1), the base asphalt is heated to a molten state at 130°C-160°C, and then the organic rectorite and composite additives are sequentially added to the melted base asphalt, stirring at 1000-2000r / min during the addition process Stir at high speed; in the process of adding compound additives, add in small amounts several times in order to stir evenly;

[...

Embodiment 1

[0039] Step 1. Heat 500g of asphalt to 135°C, slowly add 5g of organic rectorite at a stirring speed of 2000r / min, then add 0.5g of maleic anhydride and 2.5g of aromatic diamine chain extender and stir for 2min to obtain mixture A ;

[0040] Step 2. At a stirring rate of 2000r / min, slowly add a mixture B of 25g of polyurethane prepolymer and 0.05g of tetraerythritol ester at 90°C to mixture A, and keep stirring at 135°C for 10min at 2000r / min to obtain a mixture C;

[0041] Step 3. Finally, add 1.25 g of dimethyl methylphosphonate at 1000 r / min, continue to maintain the temperature and speed and stir for 2 minutes to obtain modified asphalt.

Embodiment 2

[0043] Step 1. Heat 500g of asphalt to 130°C, slowly add 7g of organic rectorite at a stirring speed of 1000r / min, then add 0.7g of maleic anhydride and 3.5g of aromatic diamine chain extender and stir for 5min to obtain mixture A ;

[0044] Step 2. At a stirring rate of 2000r / min, slowly add a mixture B of 35g of polyurethane prepolymer and 0.1g of antioxidant 1010 at 90°C to the mixture A, and keep stirring at 135°C for 10min at 2000r / min to obtain a mixture C;

[0045] Step 3. Finally, add 1.75 g of dimethyl methylphosphonate at 1000 r / min, continue to maintain the temperature and speed and stir for 2 minutes to obtain modified asphalt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com