Recovering method for valuable metal in waste nickel-cobalt-manganese-lithium ion battery

A technology of nickel-cobalt-manganese-lithium and valuable metals, which is applied in the field of recycling valuable metals in waste nickel-cobalt-manganese lithium-ion batteries, can solve the problems of high processing cost, difficult application, and large number of processes, and achieve process and equipment simplification , simplify the reaction equipment, simplify the effect of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be described in detail below with reference to the embodiments.

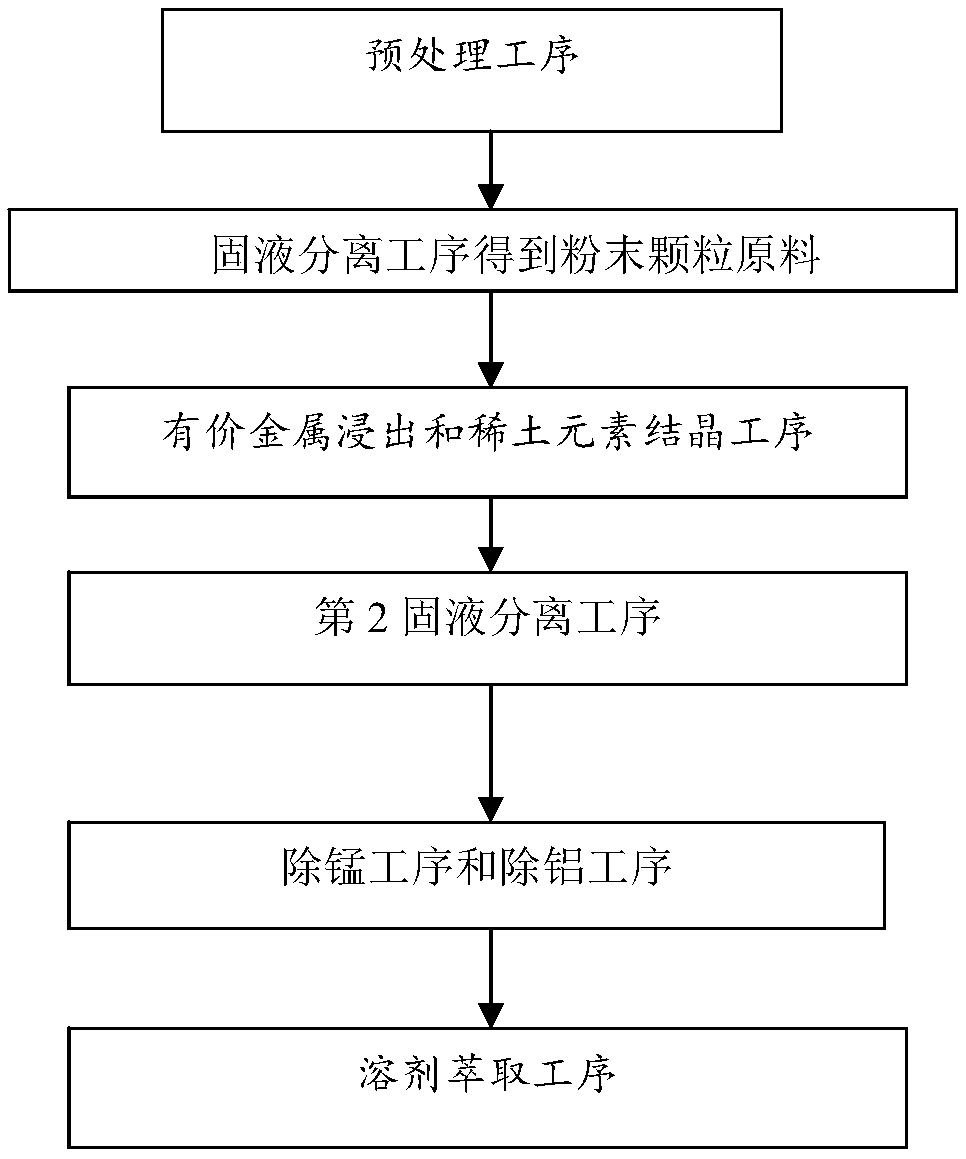

[0048] A method for recovering valuable metals in waste nickel-cobalt-manganese lithium-ion batteries, comprising the following steps:

[0049] (1) Pretreatment process

[0050] The waste nickel-cobalt-manganese lithium-ion battery is disassembled, discharged and broken, and the positive and negative electrode materials are roughly selected, and the positive and negative electrode materials are pulverized; sieved to obtain powder particles; in order to remove the soluble in the powder particles Water-soluble alkali metal salts such as potassium and sodium of water, add water to the powder particles and stir, and stir to obtain a cleaning liquid slurry, and the solid-liquid separation of the cleaning liquid slurry, the obtained powder particles are the solid valuable Metal recycling raw materials;

[0051] (2) The leaching process of nickel, cobalt, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com