A kind of marine low magnetic steel and preparation method thereof

A low magnetic steel, marine technology, applied in the field of alloy structural steel manufacturing, can solve the problem of loss of shielding effect, and achieve the effect of simple production process, low magnetic permeability and excellent plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

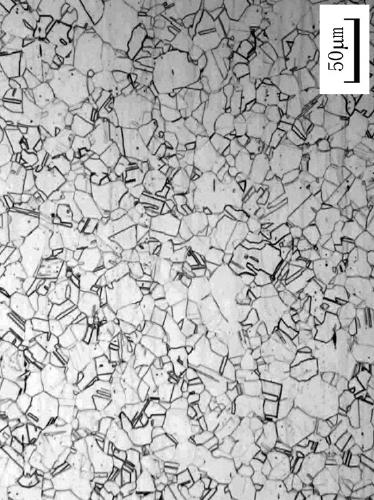

Image

Examples

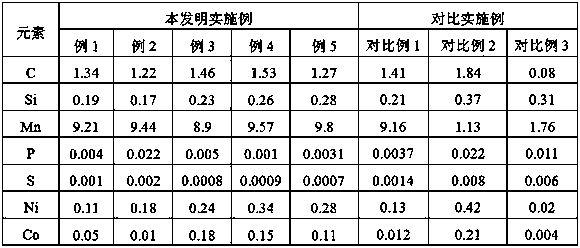

Embodiment 1

[0034] A kind of marine low magnetic steel of this embodiment, its chemical composition and its mass percentage are: C 1.34%, Si 0.19%, Mn 9.21%, P 0.004%, S 0.001%, Ni 0.11%, Co 0.05%, balance The amount is Fe and unavoidable impurities.

[0035] A kind of preparation method of marine low magnetic steel of the present embodiment comprises the following steps:

[0036] (1) Smelting and casting

[0037] Add molten iron with a mass fraction P≤0.050%, S≤0.020% and temperature T≥1280°C in the molten iron tank, then carry out deep desulfurization treatment on the molten iron through the KR desulfurization process, and then enter the top-bottom combined blowing converter for smelting, adding desulfurization Phosphorus agent reduces the phosphorus content in molten iron to P≤0.005%, adding desulfurizer to reduce the sulfur content in molten iron to S≤0.002%, adding alloy materials SiFe, MnFe, FeNi, Co to adjust the content of Si in molten iron to 0.19%, The content of Mn is 9.21%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com