A kind of steel plate for large heat input welding and preparation method thereof

A technology for high-energy-input welding and steel plates, which is applied in the field of steel plates for high-energy-input welding and its preparation, can solve problems such as low-temperature toughness, strength, and weldability that are difficult to meet, and achieve excellent low-temperature toughness, improve yield strength, and produce The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

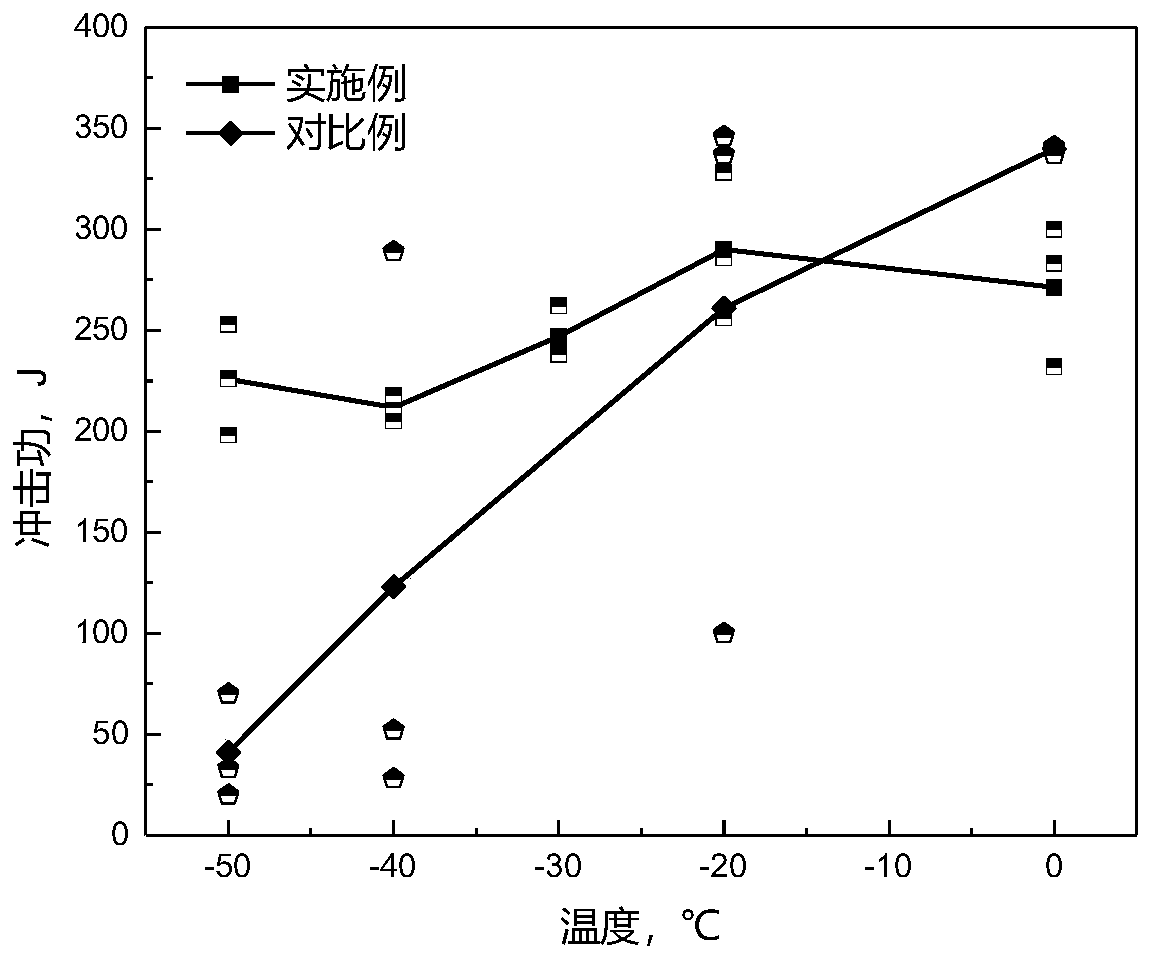

Embodiment 1

[0059] Example 1: Heat the slab to 1100°C, holding time 0.5h, the first stage rough rolling start temperature is 1050°C, after 3 passes of rough rolling, the first stage rough rolling finish rolling temperature is 950°C, the second stage finish The rolling start temperature is 820°C, after 2 passes of finish rolling, the finishing rolling temperature of the second stage is 800°C, and the start rolling temperature of the third stage two-phase zone is 780°C, after 2 passes of rolling, the thickness of the steel plate is rolled to 12mm, the final rolling temperature is 760°C, and then air-cooled to room temperature.

Embodiment 2

[0060] Example 2: Heating the cast slab to 1100°C, holding time for 0.5h, the first stage rough rolling start temperature is 1058°C, after 3 passes of rough rolling, the first stage rough rolling finish rolling temperature is 965°C, the second stage finish The rolling start temperature is 816°C, after 2 passes of finish rolling, the finish rolling temperature of the second stage is 796°C, and the start rolling temperature of the third stage two-phase zone is 776°C, after 2 passes of rolling, the thickness of the steel plate is rolled to 12mm, the final rolling temperature is 757°C, and then air-cooled to room temperature.

Embodiment 3

[0061] Example 3: Heating the cast slab to 1100°C, holding time for 0.5h, the first stage rough rolling start temperature is 1065°C, after 3 passes of rough rolling, the first stage rough rolling finish rolling temperature is 960°C, the second stage finish The rolling start temperature is 800°C, after 2 passes of finish rolling, the finish rolling temperature of the second stage is 795°C, and the start rolling temperature of the third stage two-phase zone is 773°C, after 2 passes of rolling, the thickness of the steel plate is rolled to 12mm, the final rolling temperature is 754°C, and then air-cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com