Coal mine gas extracting and drilling monitoring management system

A technology for monitoring management and extraction of boreholes, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as potential safety hazards, low acceptance efficiency, and poor timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

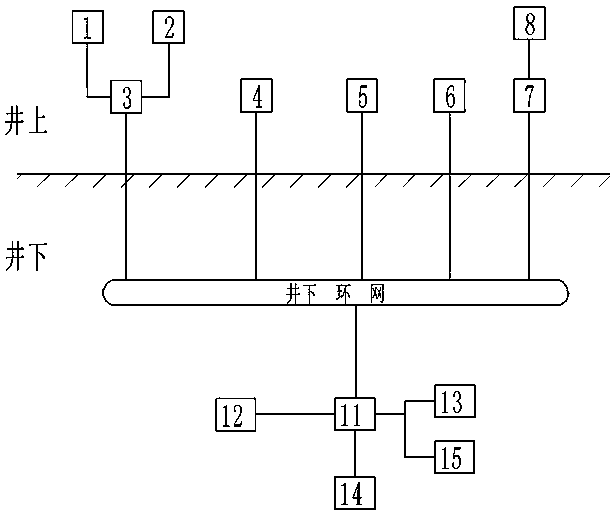

[0026] Such as figure 1 As shown, a coal mine gas drainage drilling monitoring and management system includes an uphole management server system, an underground ring network, and an underground gas drainage drilling site monitoring device. The uphole management server system includes a speaker 1, a microphone 2, a monitoring terminal 3, and a server 5. The network video recorder 6, the extended memory 4, the video decoder 7 and the large-screen splicing video wall 8, and the video decoder 7 is connected to the large-screen splicing video wall 8. The speaker 1 and the microphone 2 are connected to the monitoring terminal 3 respectively. The monitoring terminal 3, the extended memory 4, the server 5, the network video recorder 6, the video decoder 7 and the control box 11 are all connected to the underground ring network;

[0027] The underground gas dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com