An optical module fault diagnosis system and method

A fault diagnosis system and fault diagnosis technology, applied in the direction of optical instrument testing, machine/structural component testing, instruments, etc., can solve the problems of limited information, limited storage space of optical modules, lack of storage devices, etc., and achieve abundant resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

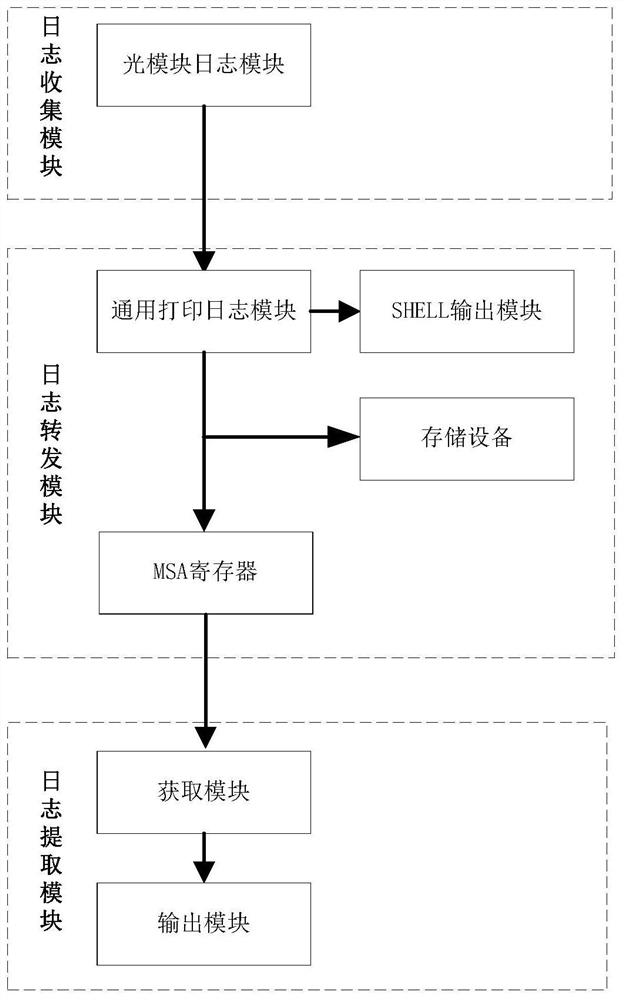

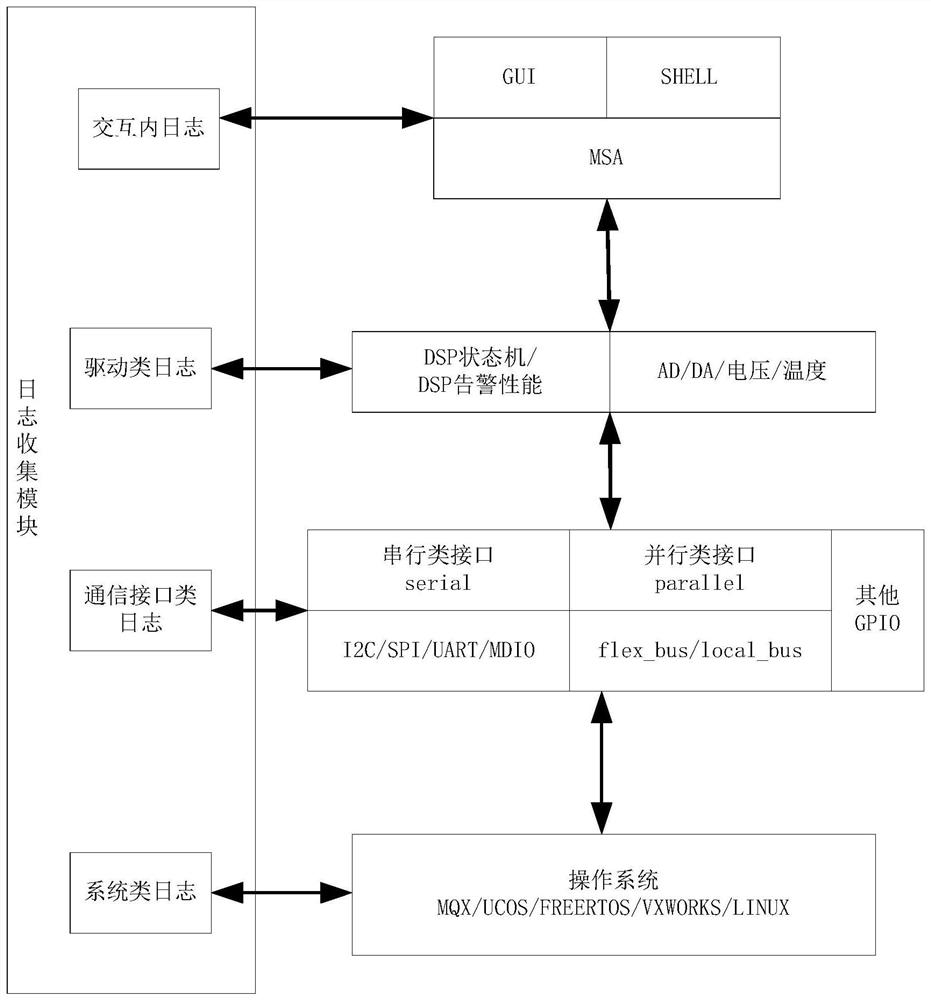

[0042] see figure 1 As shown, the embodiment of the present invention provides an optical module fault diagnosis system, including:

[0043] The log collection module is used to collect log information during the photoelectric signal conversion process of the optical module and provide it to the log forwarding module; the log collection module specifically includes a log collection module, and the log collection module is used to collect log information generated by the optical module. These log information mainly include the hardware running status of the module, the response feedback during the interaction with the outside world, and the running status of the internal software. These log information will be recorded actively (by timing recording) or passively (by responding to commands), and the recorded log information will be processed by the log forwarding function.

[0044]The log forwarding module is used to process the collected log information and forward it to the s...

Embodiment 2

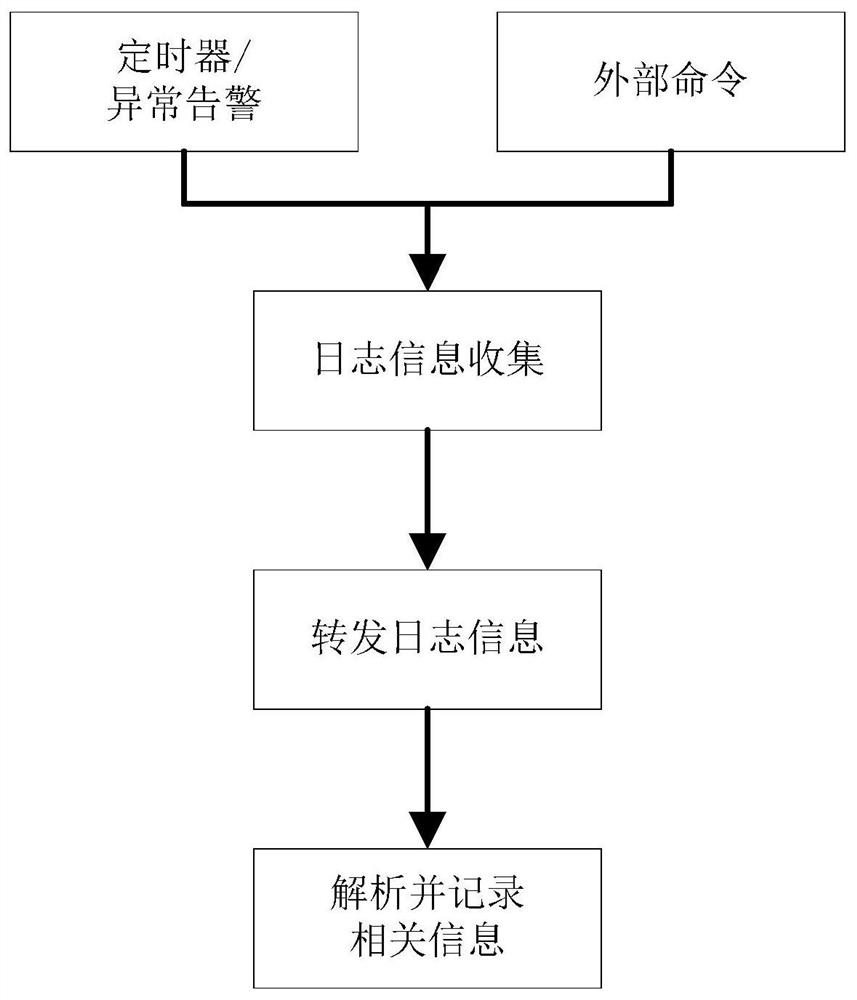

[0052] Such as figure 2 As shown, the present invention also provides an optical module fault diagnosis method using the aforementioned optical module diagnostic device, comprising the following steps:

[0053] S1. Use the log collection module to collect the log information of the photoelectric signal conversion process, such as the operating status parameters of various internal devices, various task stack information at the operating system level, error information on the number of reads and writes at the driver level, and various information on the application level. Business-related alarm performance information, command information at the interaction level, etc., after collecting all the information, pass the log information to the log forwarding module;

[0054] S2. The log forwarding module uses the general printing log module of the optical module to process the collected log information, and forwards it to the serial port of the optical module, the storage device an...

Embodiment 3

[0057] This embodiment provides a method for diagnosing an optical module fault using the aforementioned optical module diagnostic device, which includes not only all the steps in Embodiment 2, but also a process of generating and recording an optical module log before step S1.

[0058] The optical module log supports both internal automatic recording and external trigger recording. In this embodiment, the recording of the optical module log is completed through internal automatic recording. The specific method is: before step S1, set the log collection module to regularly query all hardware and software information and organize and record it as log information. For example, use a timer to trigger regular query, set it to be triggered once an hour, after triggering, the log module will query all hardware and software information and organize records; or set the log collection module to send Relevant information is recorded as log information. For example, when the service is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com