Automatic identification device and method of optical fiber fusion splicer

An optical fiber fusion splicer and automatic identification technology, applied in the directions of light guides, optics, optical components, etc., can solve the problems of difficulty in distinguishing optical fibers, restricting motion accuracy, and difficult to keep up, avoiding mis-splicing, improving the quality of optical fiber fusion, and adjusting fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

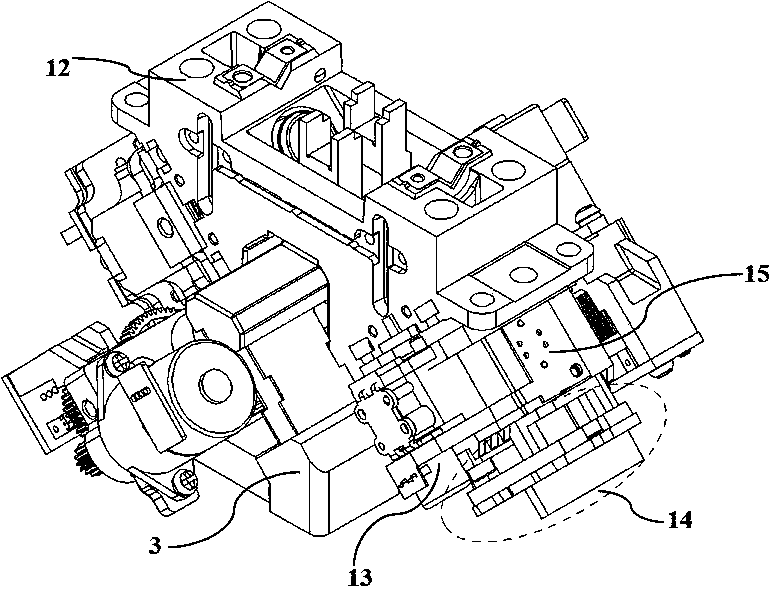

[0029] The automatic identification device of the optical fiber fusion splicer in this embodiment is as follows: figure 1 As shown, automatic focusing is realized by an automatic focusing motor 13 , a camera assembly 14 and an automatic focusing lens assembly 15 installed on a central mounting bracket 12 . There are 45° slopes on both sides of the center mounting bracket 12 for installing the auto-focusing lens assembly 15 , the slopes on both sides are symmetrical to each other, and the center mounting bracket 12 is fixedly connected to the centering frame base 3 .

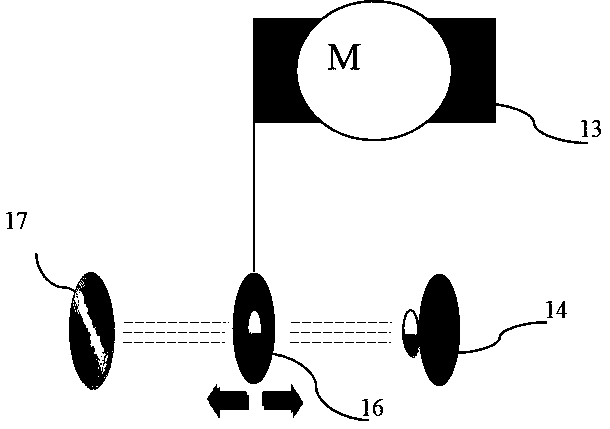

[0030] The principle of automatic focus adjustment is as follows: figure 2 As shown, the autofocus motor 13 drives the adjusting lens 16 to move linearly, and the focal length of the lens assembly formed with the fixed lens 17 changes, and automatically adapts when the position and type of the optical fiber change, ensuring the imaging accuracy of the camera assembly 14. The imaging accuracy meets the needs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com