A four-phase dual-winding vernier motor

A vernier motor and double winding technology, applied in the shape/style/structure of winding conductors, electromechanical devices, electrical components, etc., can solve the problem of motor power density and torque density reduction, motor high positioning torque and torque ripple, motor Reduce the utilization rate of permanent magnets and other problems, achieve the effect of increasing power density and torque density, reducing internal magnetic flux leakage, and reducing the number of blocks used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below according to the drawings and specific embodiments of the description.

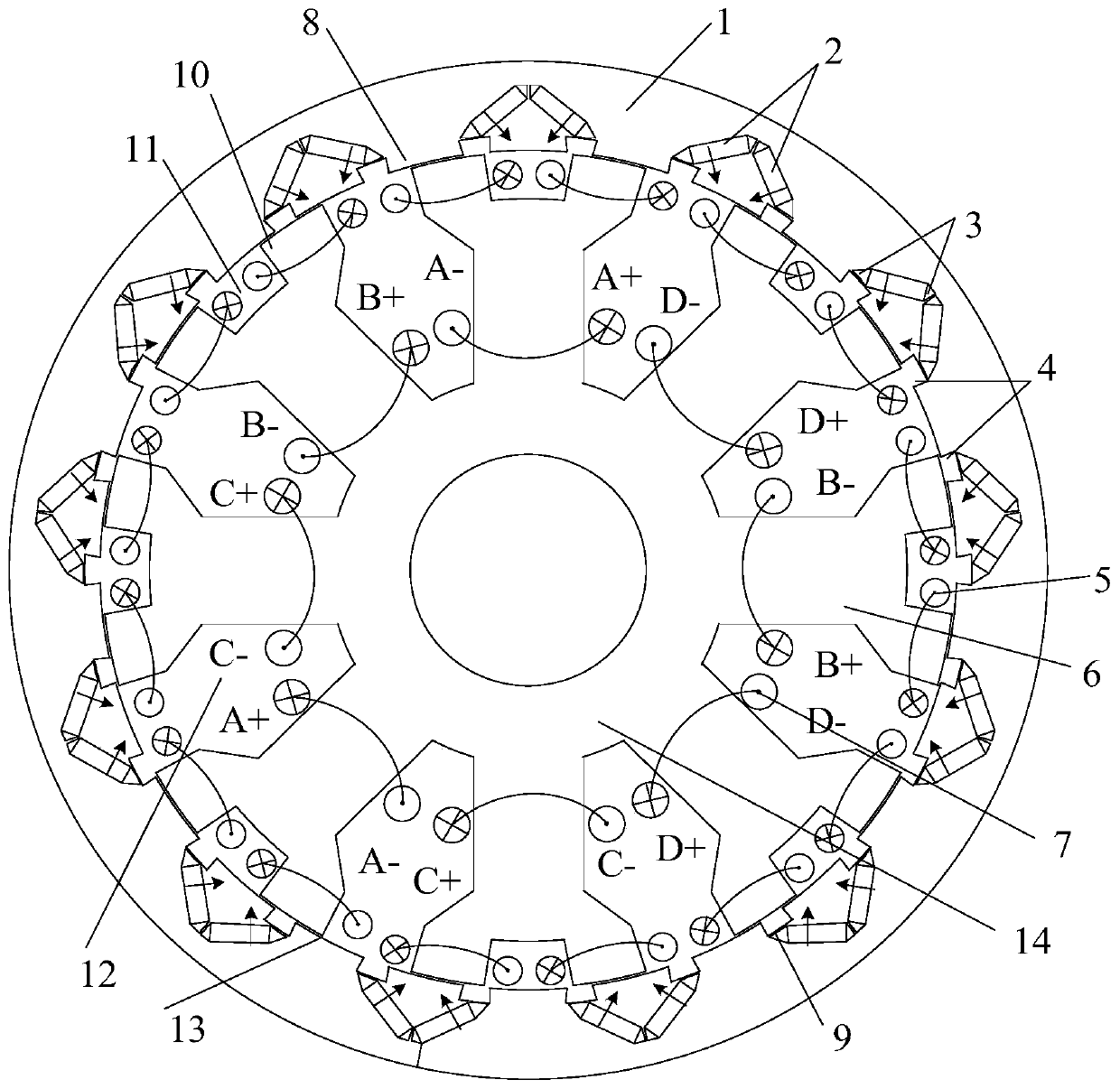

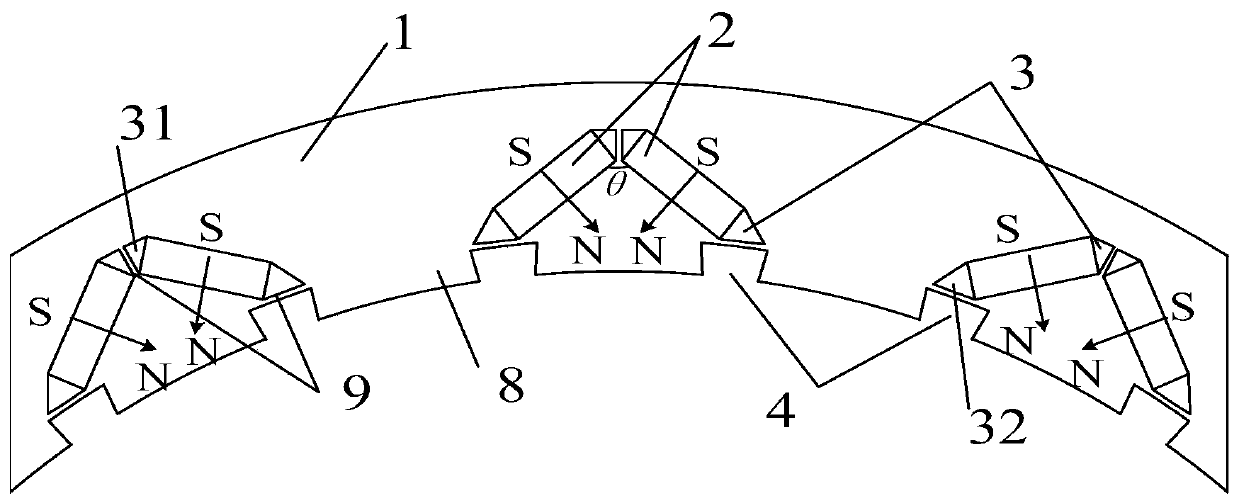

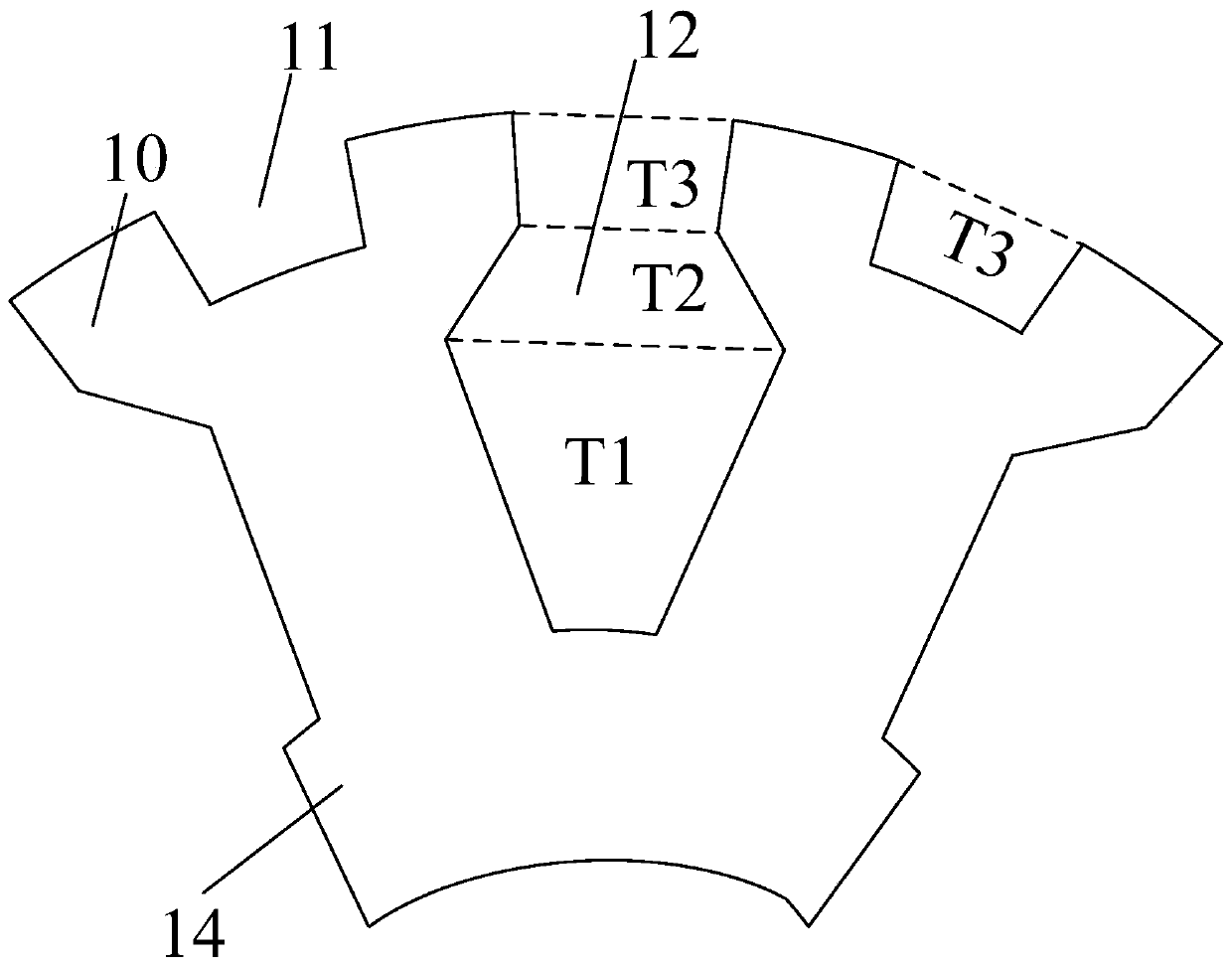

[0036] see figure 1 , figure 2 and image 3, The present invention includes a rotor 1 , an air gap 13 , and a stator 6 arranged concentrically from the outside to the inside, and the air gap 13 is set between the rotor 1 and the stator 6 . The rotor includes 26 rotor teeth 8 arranged at equal intervals along the circumference, 26 rotor false slots 4 arranged between the rotor teeth, permanent magnets 2 with the same number as the rotor false slots 4, one end of which is placed in contact with the rotor false slots 4 The other end is located above the rotor teeth 8 between the dummy slots 4 of the rotor. Therefore, two permanent magnets 2 form a V-shaped structure, and the included angle θ of the V-shaped structure formed by the permanent magnets 2 needs to satisfy the condition of 60°≤θ≤120°. The two ends of each permanent magnet 2 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com