Method for rapidly fermenting sweet bean petals in stages

A staged, Douban technology, applied in the field of fast fermentation of Douban Tianbanzi in stages, can solve the problems of inhibiting protease, slowing down the rate of protein decomposition, prolonging the fermentation period, etc., achieving fast fermentation speed, complete petal shape, and petal fragrance. Soft and harmonious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

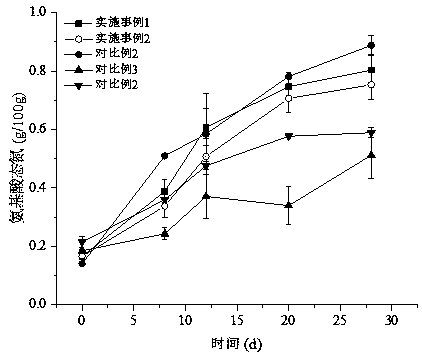

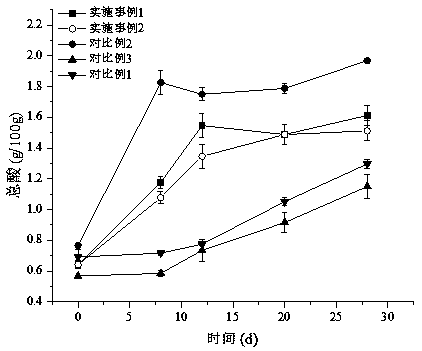

Examples

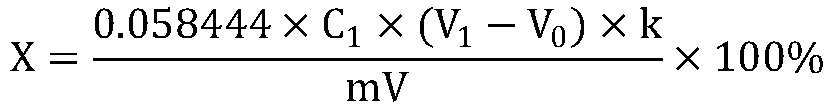

Embodiment 1

[0024] A kind of method for phase-by-stage rapid fermentation of Douban sweet petals by temperature and salinity, the method comprises the following steps:

[0025] Preparation of sweet petals

[0026] (1) Hot petals: 5 kg of dried broad bean petals that have been shelled, removed impurities, added an appropriate amount of boiling water to blanch for about 4 minutes, filtered, and cooled.

[0027] (2) Koji inoculation

[0028] Add flour with 17% of the mass of broad beans, and add an appropriate amount of Qujing Shanghai Niang 3.042 to make the amount of mold in the broad bean mixture reach 10 6 CFU / g; Humidity 80%, cultured at 30°C for 48 hours, turning once every 12 hours.

[0029] (3) Production of sweet bean seeds: under aseptic conditions, mix Doubanqu and saline at a mass ratio of 1:1.2 (add salt and water at a time, and the final concentration of salt is 6%), and stir evenly.

[0030] Fermentation is carried out in several stages:

[0031] The first stage: low salt ...

Embodiment 2

[0035] A kind of method for phase-by-stage rapid fermentation of Douban sweet petals by temperature and salinity, the method comprises the following steps:

[0036] Preparation of sweet petals

[0037] (1) Hot petals: 5 kg of dried broad bean petals that have been shelled, removed impurities, added an appropriate amount of boiling water to blanch for about 4 minutes, filtered, and cooled.

[0038] (2) Koji inoculation

[0039] Add flour with 17% of the mass of broad beans, and add an appropriate amount of Qujing Shanghai Niang 3.042 to make the amount of mold in the broad bean mixture reach 10 6 CFU / g; Humidity 80%, cultured at 30°C for 48 hours, turning once every 12 hours.

[0040] (3) Production of sweet bean seeds: under sterile conditions, mix watercress koji and saline at a mass ratio of 1:1 (add salt and water at a time, and the final concentration of salt is 9%), and stir evenly.

[0041] Fermentation is carried out in several stages:

[0042] The first stage: low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com