Multi-stage solvent extraction preparation method of cocoa extract and application

An extract and solvent technology, which is applied in the field of multi-level solvent extraction and preparation of cocoa extracts, can solve problems such as the inability to achieve effective comprehensive utilization of cocoa and the inability to effectively extract components, and achieves improved application value, rich functional components, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

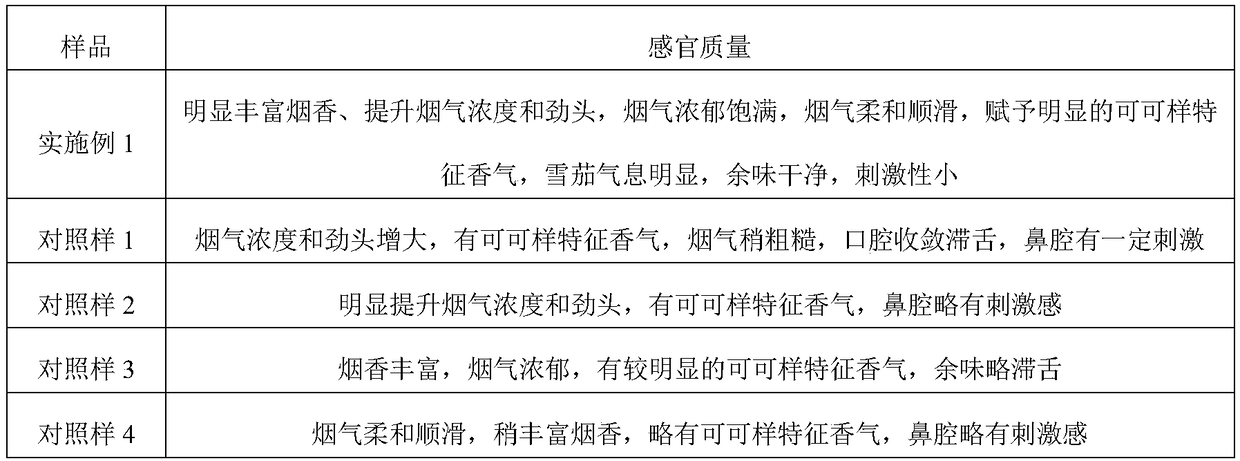

Embodiment 1

[0028] A preparation method for multistage solvent extraction of cocoa extract, which comprises the following steps:

[0029] (1) Take 1 part of cocoa powder, add 15 parts by weight of ethanol with a pH value of 1.5 (adjusted by disodium hydrogen phosphate-citric acid buffer solution), and a mass concentration of 40% as an acidic solvent, extract at 70 ° C for 2 hours, and cool , 0.8 μm membrane filter, obtain filtrate A and filter residue A;

[0030] (2) Take 1 part of filter residue A, add 8 parts by weight of ethanol with a pH value of 7.0 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) and 40% mass concentration as a neutral solvent, and extract at 70 ° C for 1.5 h , cooled, and filtered through a 0.8 μm filter membrane to obtain filtrate B and filter residue B;

[0031] (3) Take 1 part of filter residue B, add 8 parts by weight of ethanol with a pH value of 8.4 (adjusted by disodium hydrogen phosphate-citric acid buffer solution), and a mass concent...

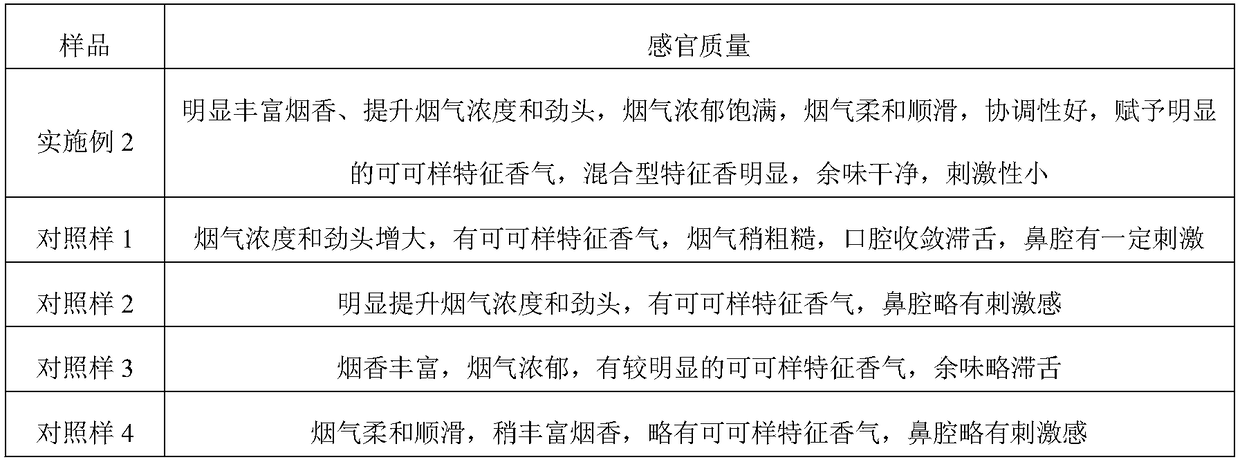

Embodiment 2

[0037] A preparation method for multistage solvent extraction of cocoa extract, which comprises the following steps:

[0038] (1) Take 1 part of cocoa powder, add 15 parts by weight of 40% ethanol with a pH value of 1.8 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) as an acidic solvent, extract at 70 ° C for 2 hours, cool, 0.8 μm Membrane filtration, obtain filtrate A and filter residue A;

[0039] (2) Take 1 part of filter residue A, add 8 parts by weight of 40% ethanol with a pH value of 6.6 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) as a neutral solvent, extract at 70° C. for 1.5 h, cool, Filtrate with a 0.8 μm filter membrane to obtain filtrate B and filter residue B;

[0040](3) Take 1 part of filter residue B, add 6 parts by weight of 40% ethanol with a pH value of 8.2 (adjusted with disodium hydrogen phosphate-citric acid buffer solution) as an alkaline solvent, extract at 70 ° C for 1 h, cool, 0.8 μm filter membrane ...

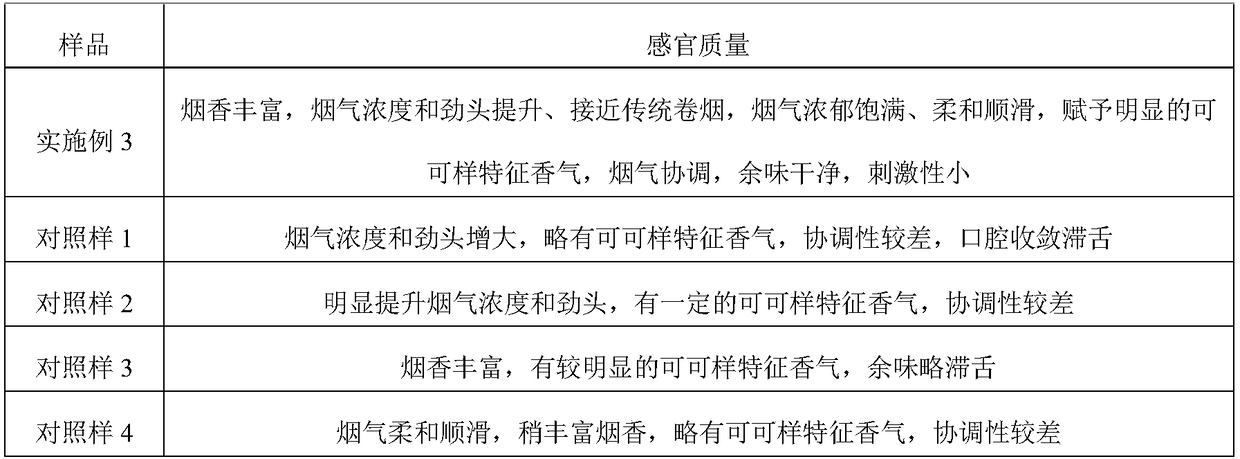

Embodiment 3

[0046] A preparation method for multistage solvent extraction of cocoa extract, which comprises the following steps:

[0047] (1) Take 1 part of cocoa powder, add 12 parts by weight of 40% ethanol with a pH value of 1.6 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) as an acidic solvent, extract at 70 ° C for 2 h, cool, 0.8 μm Membrane filtration, obtain filtrate A and filter residue A;

[0048] (2) Take 1 part of filter residue A, add 8 parts by weight of 40% ethanol with a pH value of 6.6 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) as a neutral solvent, extract at 70° C. for 1.5 h, cool, Filtrate with a 0.8 μm filter membrane to obtain filtrate B and filter residue B;

[0049] (3) Take 1 part of filter residue B, add 6 parts by weight of 40% ethanol with a pH value of 8.4 (adjusted by disodium hydrogen phosphate-citric acid buffer solution) as an alkaline solvent, extract at 70 ° C for 1 h, cool, 0.8 μm filter membrane to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com