Modularly-combined waste gas purification apparatus

An exhaust gas purification device and exhaust gas purification technology are applied in separation devices, gas treatment, transportation and packaging, etc., which can solve the problems of safety hazards in low-temperature plasma, limited adsorption capacity of activated carbon, and low photocatalytic purification efficiency, and achieve convenient and quick assembly , compact structure, convenient and quick equipment maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

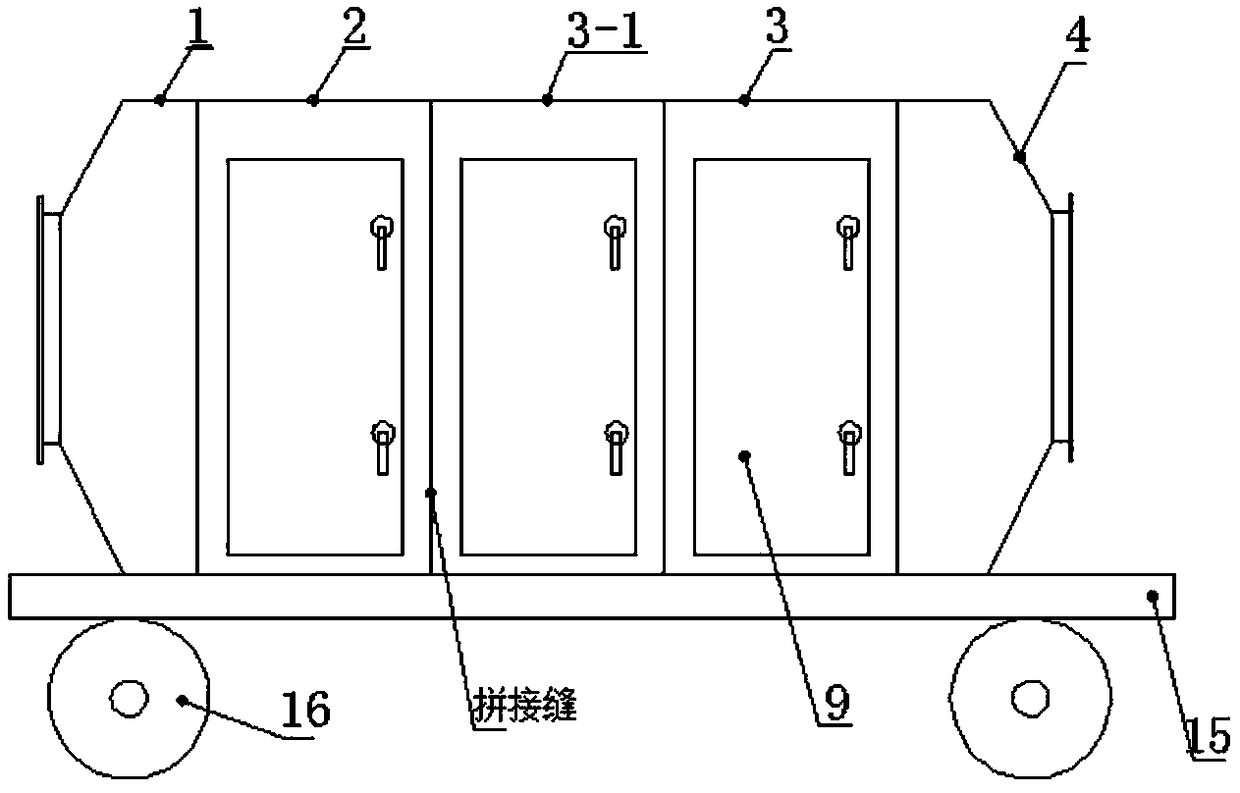

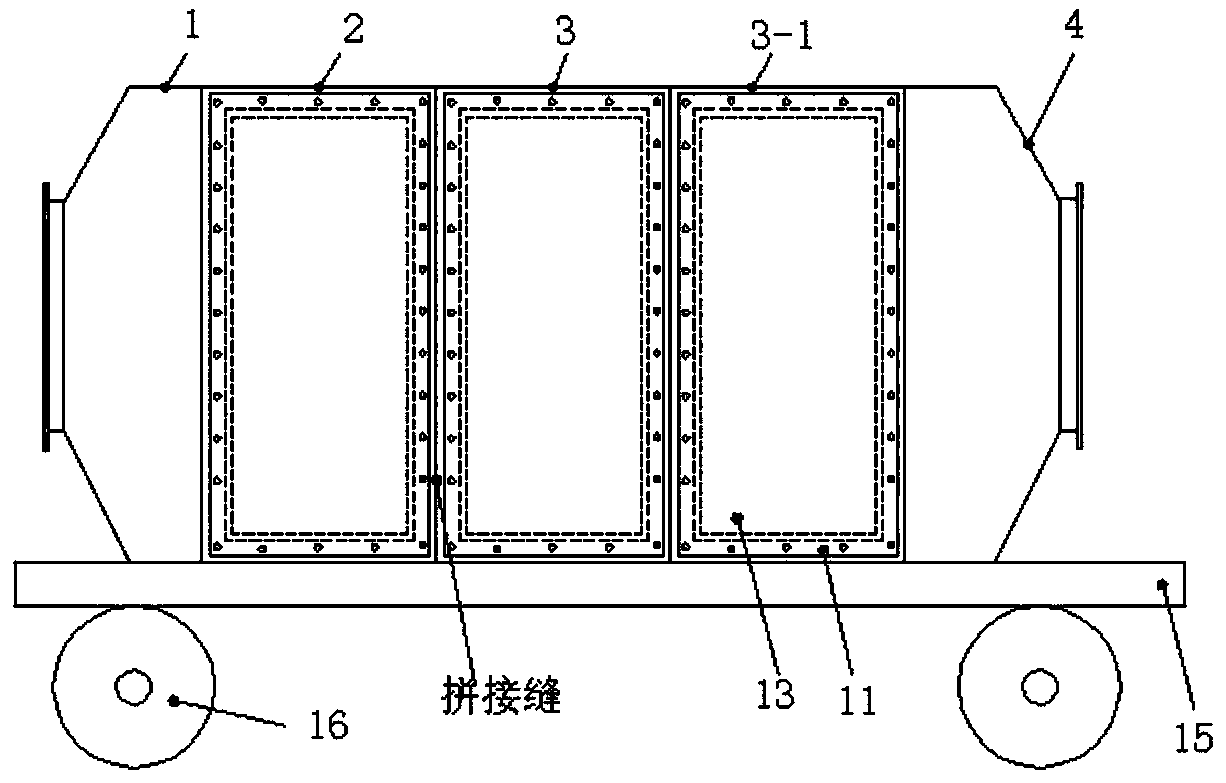

[0034] see Figure 1-Figure 8 , In one embodiment, a modular combined exhaust gas purification device is composed of a row of purification units, and the row of purification units includes an air inlet equalization section 1, a pretreatment section 2, and an exhaust gas purification section 3 connected in series in sequence And the exhaust section 4, the air inlet equalization section 1 and the pretreatment section 2, the pretreatment section 2 and the exhaust gas purification section 3, and the exhaust gas purification section 3 and the exhaust section 4 are detachably sealed and spliced together. Specifically in this embodiment, the side walls where the air inlet equalization section 1 and the pretreatment section 2, the pretreatment section 2 and the exhaust gas purification section 3, and the exhaust gas purification section 3 and the exhau...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap