Method for preparing perovskite catalyst by laser ablation

A technology of laser ablation and perovskite, applied in chemical instruments and methods, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve the problem of small specific surface area, low catalytic activity and poor thermal stability of perovskite catalysts and other issues to achieve the effect of performance improvement and catalytic performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

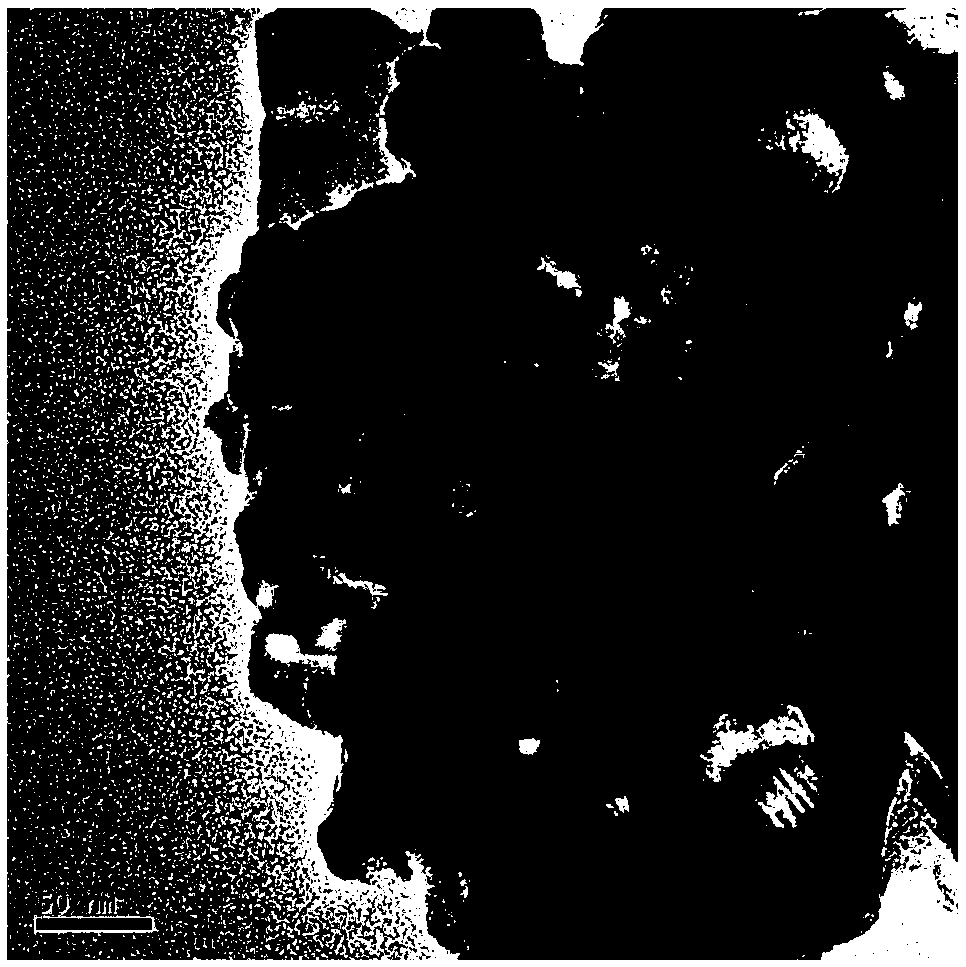

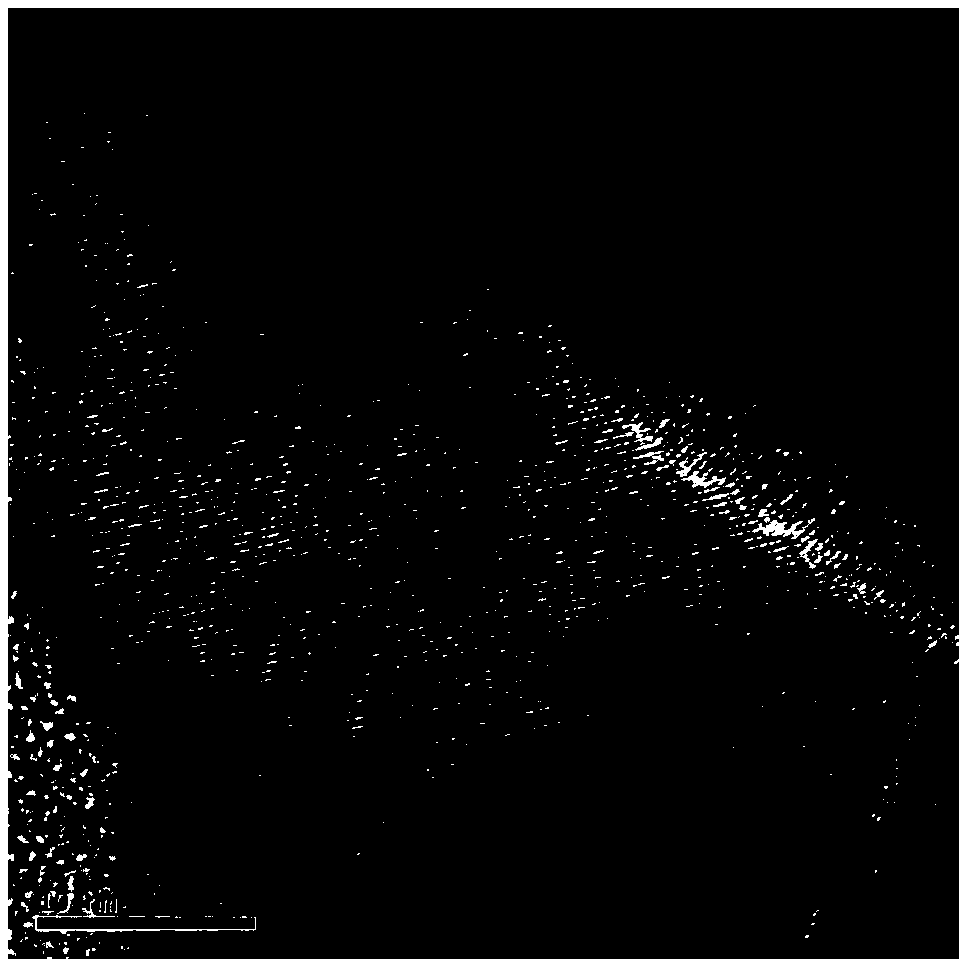

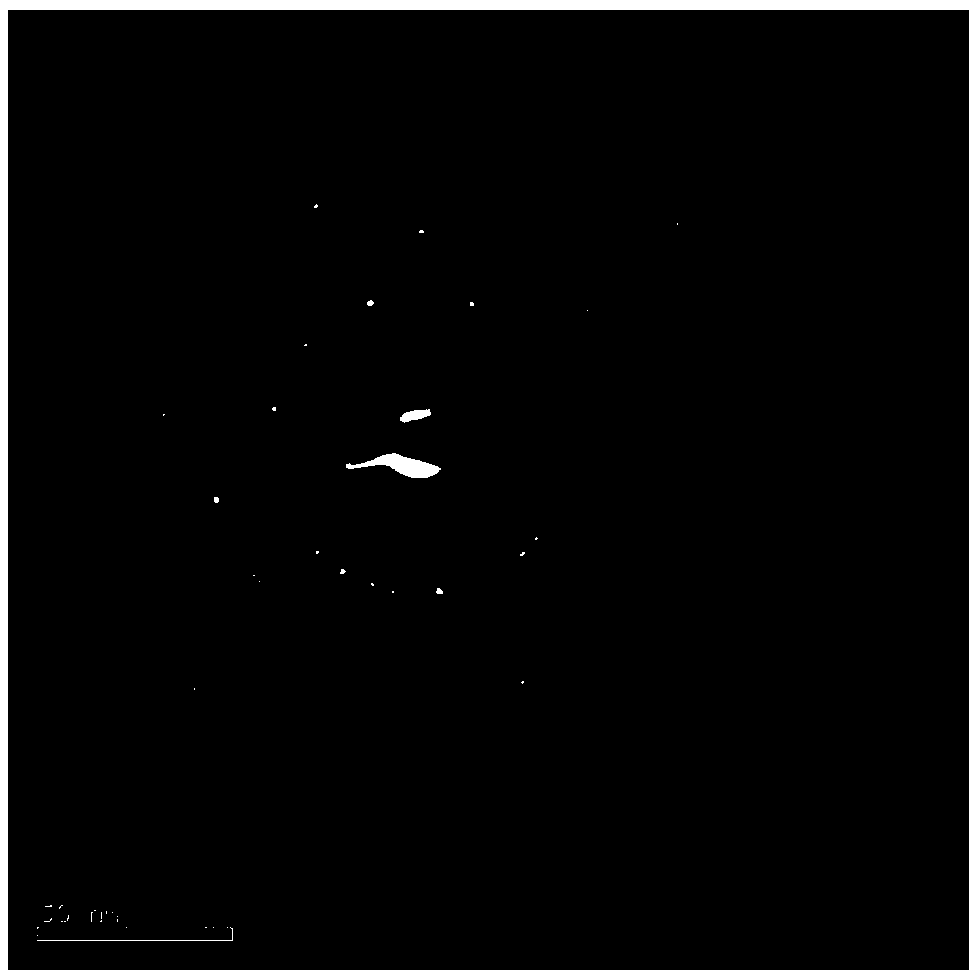

Image

Examples

Embodiment 1

[0029] Take by weighing 12.99g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 6.625g manganese acetate (C 4 h 6 MnO 4 4H 2 O) Dissolve in 600mL deionized water to form a solution with a total metal ion concentration of 0.1mol / L, then add 10.8g of glucose to the mixed solution, and stir until uniformly mixed. Then the mixture was evaporated to dryness (60°C) on a rotary evaporator until a honey-like wet gel was formed, and then the wet gel was transferred to a crucible and dried in an oven at 80°C (air atmosphere) for 12 hours to obtain a fluffy, brittle, Pale yellow dry gel;

[0030] The xerogel obtained above is fully impregnated in a platinum / palladium (Pt / Pd) mixed solution containing 1.3404g;

[0031] The temperature was raised to 400°C at 3°C / min in the air atmosphere of the muffle furnace and kept for 2 hours to completely decompose the nitrate in the precursor, and then the temperature was raised to 800°C for 3 hours at 10°C / min to prepare the perovskite catalyst.

[...

Embodiment 2

[0035] Take by weighing 12.99g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 5.880g manganese acetate (C 4 h 6 MnO 4 4H 2 O) Dissolve in 600mL deionized water to form a solution with a total metal ion concentration of 0.1mol / L, then add 10.8g of glucose to the mixed solution, and stir until uniformly mixed. Then the mixture was evaporated to dryness (60°C) on a rotary evaporator until a honey-like wet gel was formed, and then the wet gel was transferred to a crucible and dried in an oven at 80°C (air atmosphere) for 12 hours to obtain a fluffy, brittle, Pale yellow dry gel;

[0036] The xerogel obtained above is fully impregnated in a platinum / palladium (Pt / Pd) mixed solution containing 2.6808g;

[0037] The temperature was raised to 400°C at 3°C / min in the air atmosphere of the muffle furnace and kept for 2 hours to completely decompose the nitrate in the precursor, and then the temperature was raised to 800°C for 3 hours at 10°C / min to prepare the perovskite catalyst.

[...

Embodiment 3

[0040] Take by weighing 12.99g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 5.145g manganese acetate (C 4 h 6 MnO 4 4H 2 O) Dissolve in 600mL deionized water to form a solution with a total metal ion concentration of 0.1mol / L, then add 10.8g of glucose to the mixed solution, and stir until uniformly mixed. Then the mixture was evaporated to dryness (60°C) on a rotary evaporator until a honey-like wet gel was formed, and then the wet gel was transferred to a crucible and dried in an oven at 80°C (air atmosphere) for 12 hours to obtain a fluffy, brittle, Pale yellow dry gel;

[0041] The xerogel obtained above is fully impregnated in a platinum / palladium (Pt / Pd) mixed solution containing 4.0212g;

[0042] The temperature was raised to 400°C at 3°C / min in the air atmosphere of the muffle furnace and kept for 2 hours to completely decompose the nitrate in the precursor, and then the temperature was raised to 800°C for 3 hours at 10°C / min to prepare the perovskite catalyst.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com