Twine knotter

The technology of a knotter and a knotting nozzle is applied in the field of rope binding knotters, which can solve the problems of insufficient rope binding adaptability and unstable performance of a rope clamping mechanism, and achieve the effects of simple structure, low cost and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

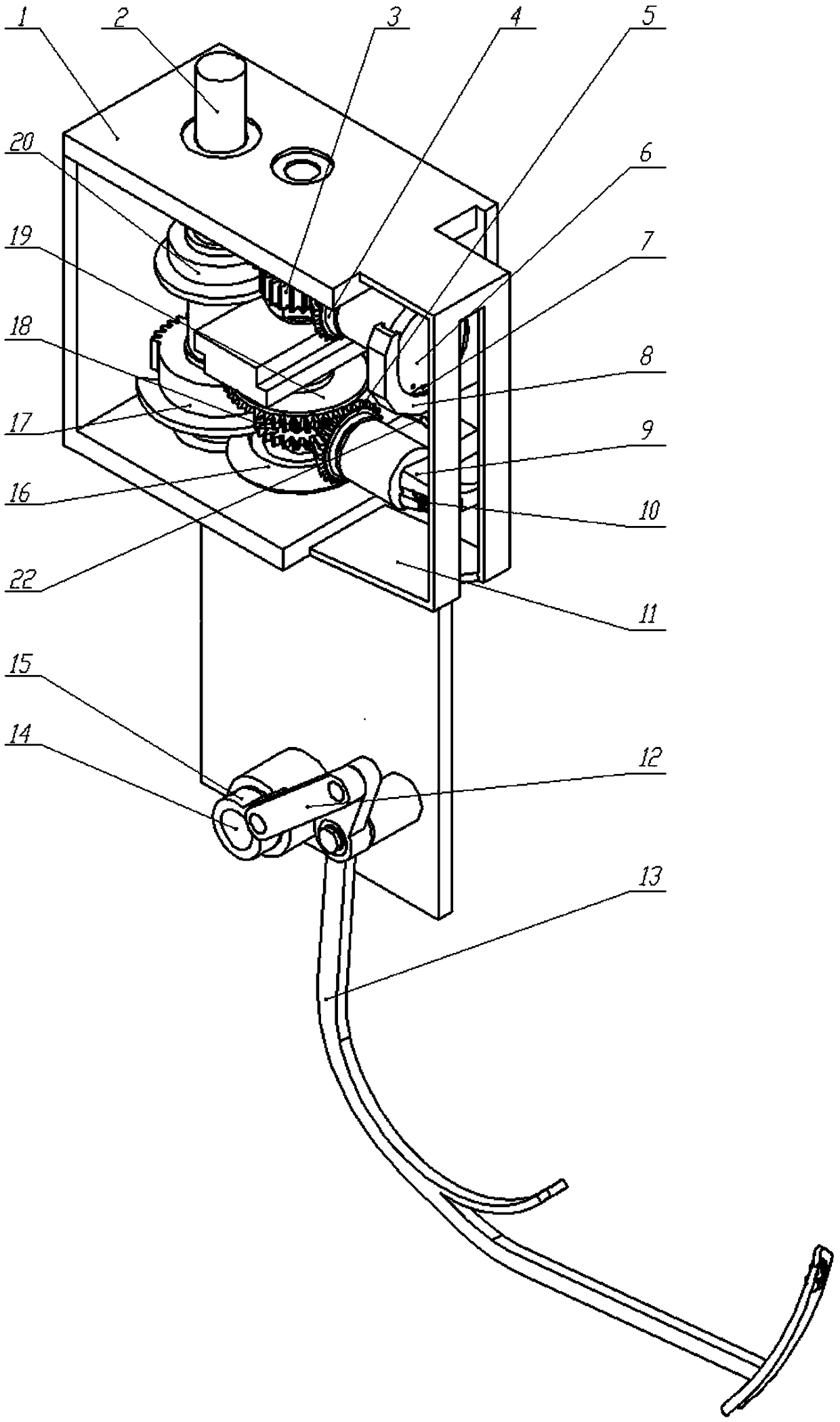

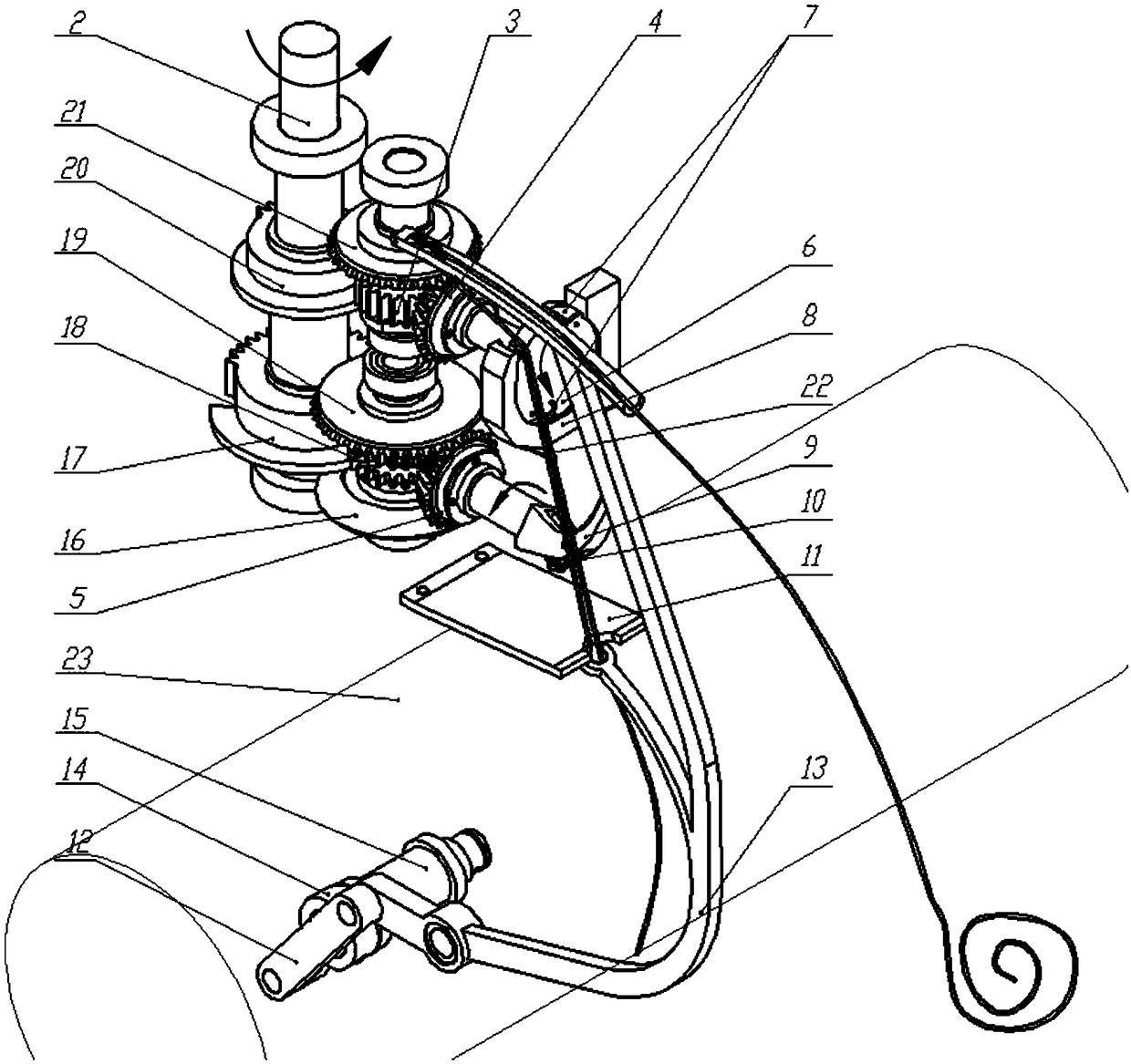

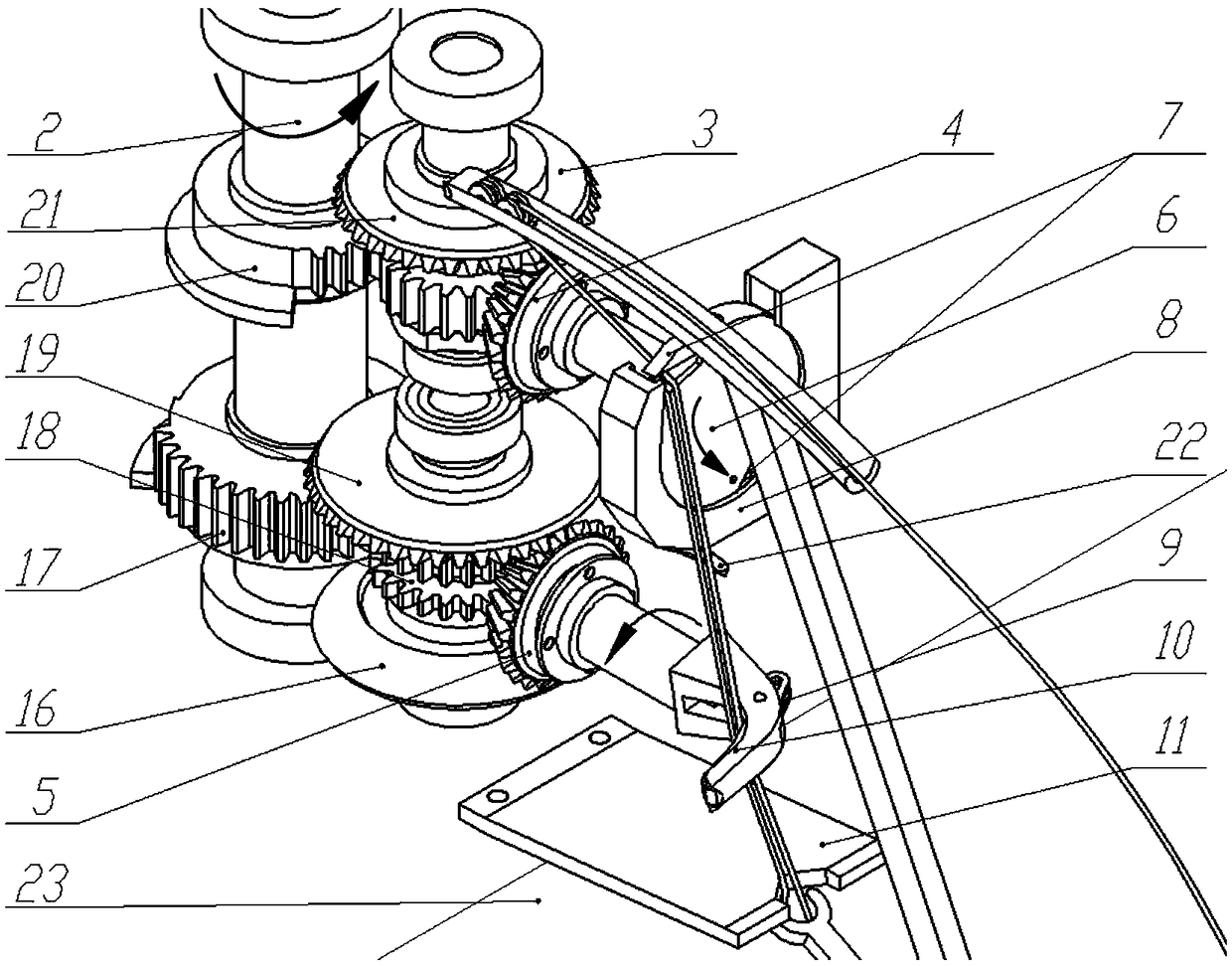

[0033] like figure 1 As shown, a rope knotter includes a frame 1, a rope feeding mechanism, a rope clamping mechanism, and a knotting mechanism.

[0034] The rope-feeding mechanism comprises a rope-feeding rotating shaft 14, a crank 15, a rope-feeding rod 13, a connecting rod 12, a driving shaft 2, a driving bevel gear and a driven bevel gear; Frame 1 bottom, crank 15 is fixedly installed on the left end of rope-feeding rotating shaft 14, and one end of rope-feeding bar 13 is rotatably installed on the bottom of frame 1, and crank 15 and rope-feeding bar 13 are positioned at the same side of frame 1, and connecting rod 12 One end is rotatably installed on the crank 15, and the other end of the crank 15 is rotatably connected with the end of the connecting end of the rope-feeding rod 13; when the rope-feeding rotating shaft 14 drives the crank 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com