High-manganese steel continuous casting method

A technology of high manganese steel and continuous casting, which is applied in the field of metallurgy, can solve problems such as urgent production demand, and achieve the effect of good internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for high manganese steel,

[0017] (1) The molten steel composition of the test steel includes C: 0.24%, Mn: 5.02%, Si: 0.27%, P: 0.0073%, S: 0.0019% and Al: 0.033%, and the production section is 280*380mm Traditional bloom casting machines;

[0018] (2) Baking in the tundish requires a small fire, and the gas flow rate is 90m 3 / h, 5.6 hours, the baking temperature is kept at 1370-1375°C, and the superheat before the machine is 26°C;

[0019] (3) 28 minutes before the start of pouring, the upper nozzle is full-scale blown with argon, and the argon blowing of the cover is closed after the pouring is started and the covering agent is added. The long nozzle is blown with argon and the valve is opened to 60%. Use magnesium coverings;

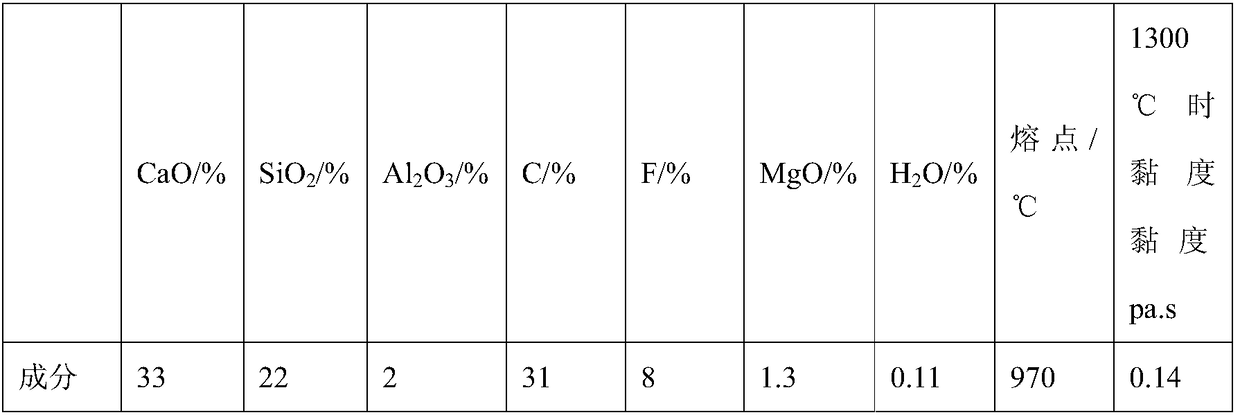

[0020] (4) Single slag line operation is used in front of the machine, the thickness of the total slag layer is controlled at 35±5mm, the speed is automatically increased, the liquid level fluctuation is controlled within ±2mm, t...

Embodiment 2

[0028] (1) The molten steel composition of the test steel includes C: 0.22%, Mn: 5.21%, Si: 0.26%, P: 0.0071%, S: 0.0018% and Al: 0.034%, and the production section is 280*380mm Traditional bloom casting machines;

[0029] (2) Baking in the tundish requires a small fire, and the gas flow rate is 95m 3 / h, 5.5 hours, the baking temperature is kept at 1361~1367°C, the superheat before the machine is 27°C, and the heat is poured;

[0030] (3) 30 minutes before the start of pouring, the upper nozzle is blown with argon at full scale, and the argon blowing of the cover is closed after the pouring is started and the covering agent is added. The long nozzle is blown with argon and the valve is opened 60%. Nozzle, strengthening protection pouring, tundish covering agent using magnesium covering agent;

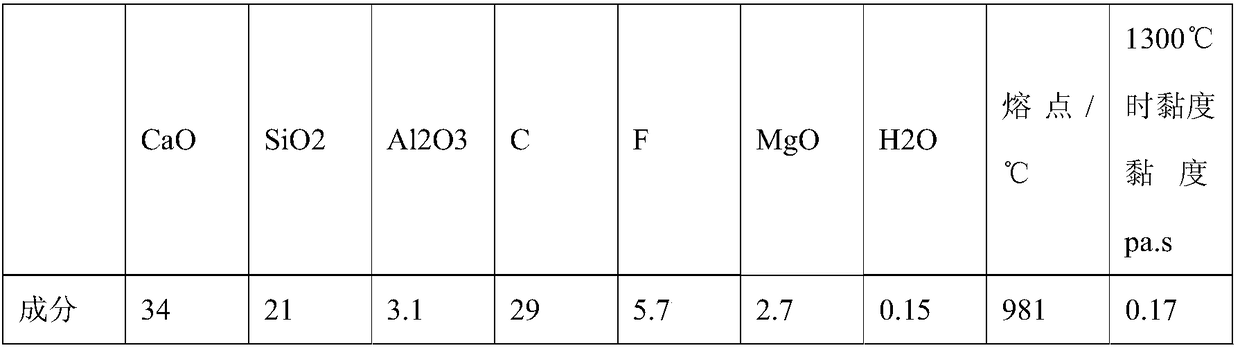

[0031] (4) Single slag line operation is used in front of the machine, the total slag layer thickness is controlled at 35±5mm, the speed is automatically increased, the liquid level ...

Embodiment 3

[0038] (1) The molten steel composition of the test steel includes C: 0.24%, Mn: 5.29%, Si: 0.29%, P: 0.0075%, S: 0.0014% and Al: 0.038%, and the production section is 280*380mm Traditional bloom casting machines;

[0039] (2) Baking in the tundish requires a small fire, and the gas flow rate is 100m 3 / h, 5.5 hours, the baking temperature is kept at 1361~1372°C, and the superheat before the machine is 26°C;

[0040] (3) 32 minutes before pouring starts, the upper nozzle is blown with argon at full scale, and the covering argon blowing is closed after the pouring is started and the covering agent is added. Magnesium covering agent is used for middle bag covering agent;

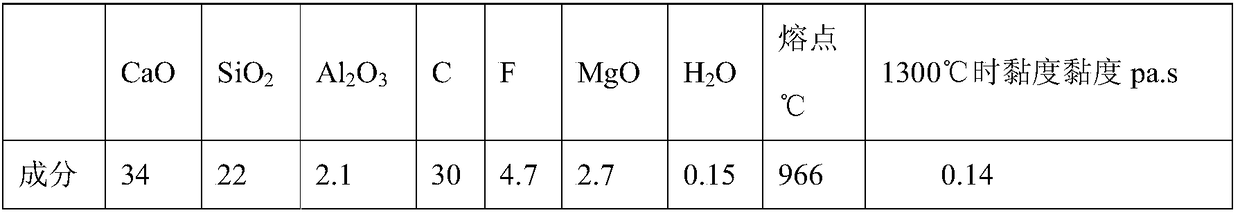

[0041] (4) Single slag line operation is used in front of the machine, the total slag layer thickness is controlled at 35±5mm, the speed is automatically increased, the liquid level fluctuation is controlled within ±2mm, the electromagnetic stirring current of the mold is 510A, the frequency is 1.6Hz, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com