Aluminum profile anodizing device capable of automatically filling electrolyte

An anodizing and automatic replenishment technology, applied in anodizing, electrode, electrolysis process, etc., can solve the problems of production quality decline and labor consumption, and achieve moderate hardness, high film porosity, and good oxidation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

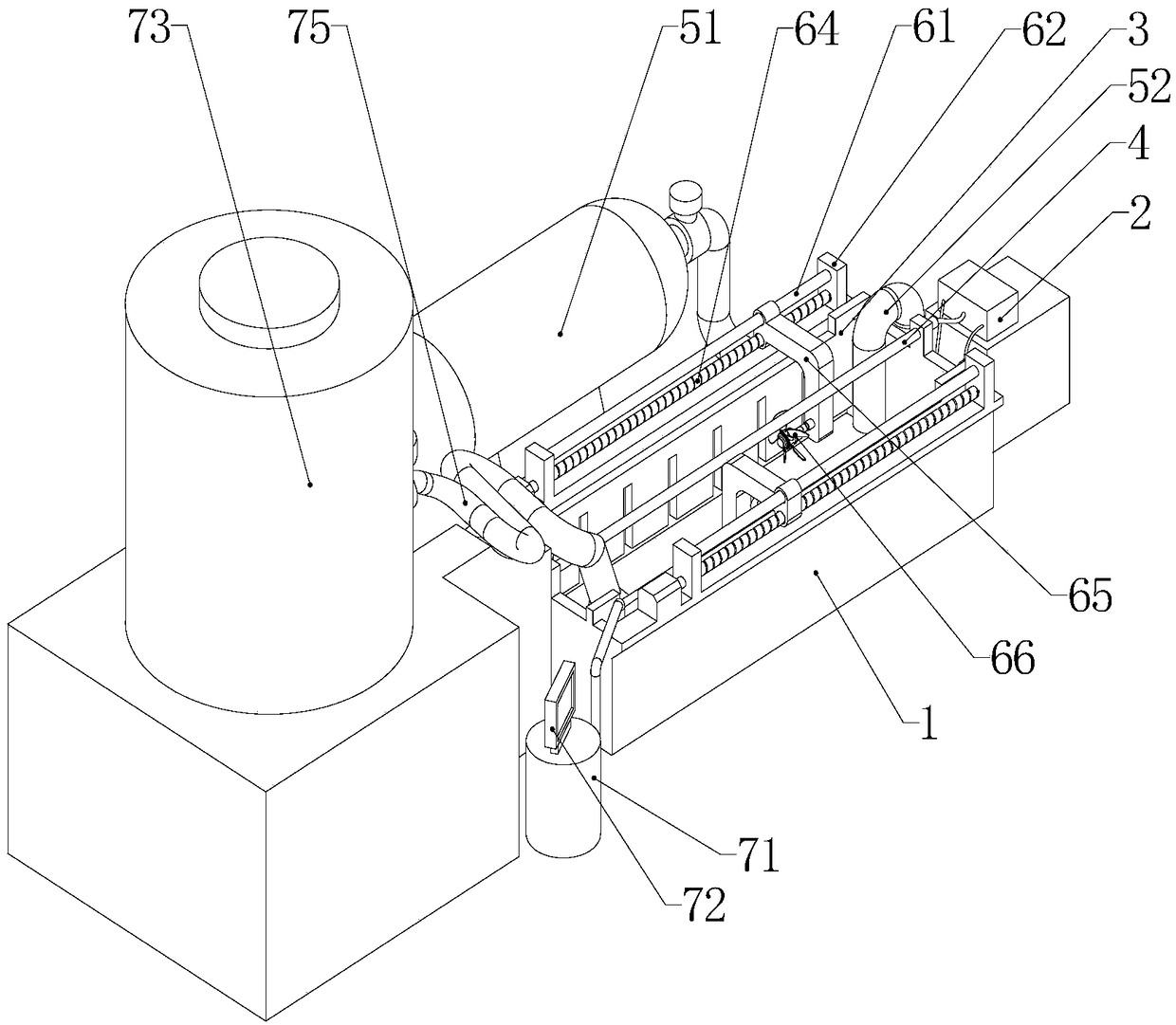

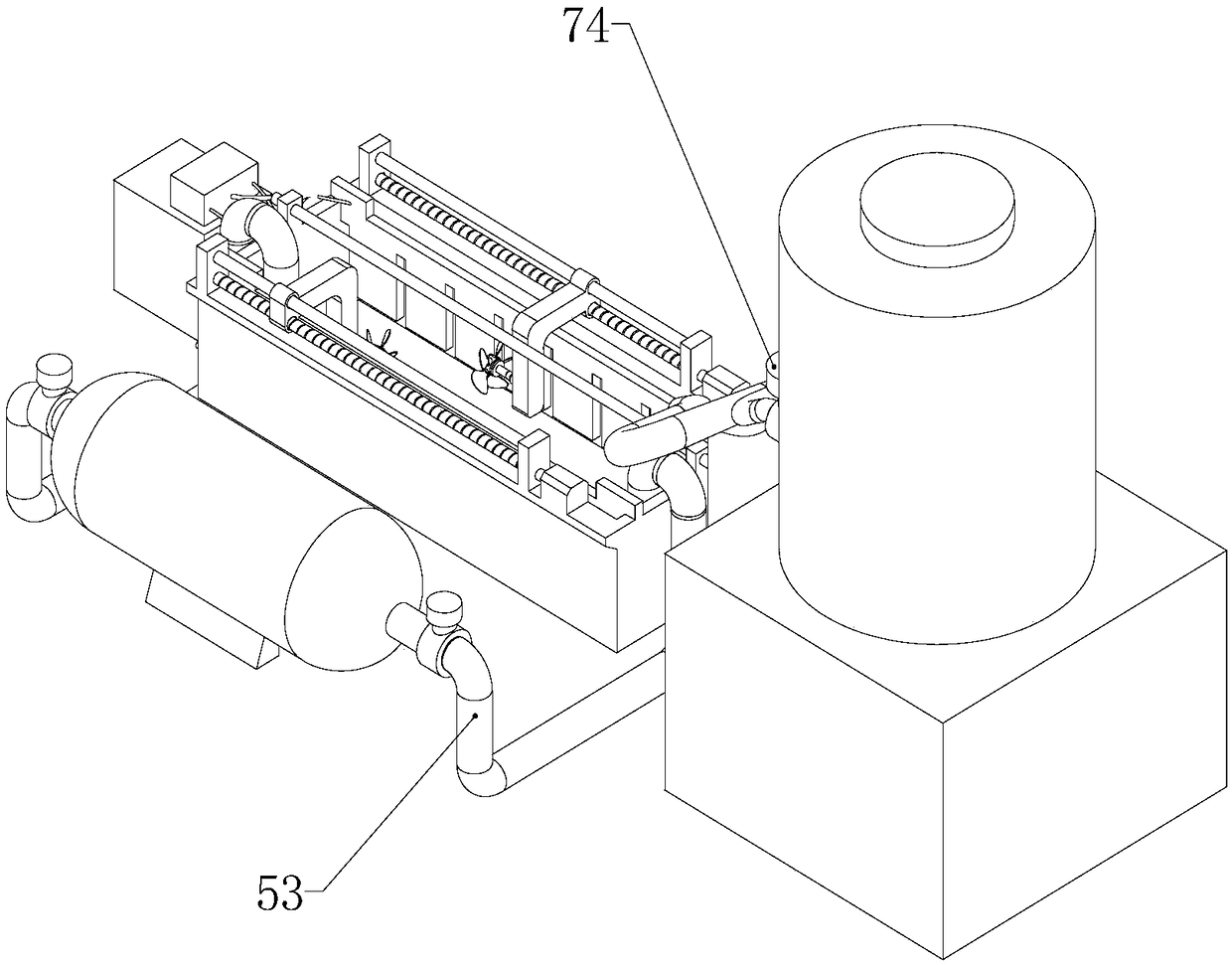

[0019] Such as figure 1 As shown, the aluminum profile anodizing device that can automatically replenish the electrolyte of the present invention is mainly composed of an electrolytic cell pool 1, a DC power supply 2, a cathode plate 3, an anode hanging rod 4, an electrolyte circulating cooling device, a stirring device and an electrolytic Liquid automatic adding device.

[0020] The electrolyzer pool 1 is a cuboid structure.

[0021] The DC power supply 2 is arranged on one side of the electrolyzer pool. There are two cathode plates, which are respectively arranged on the inner wall of the electrolytic cell 1 in the length direction, and connected to the DC power supply 2 . The anode hanging rod 4 is erected in the middle of the electrolyzer pool along the length direction of the electrolyzer pool, and is connected with the DC power supply 2 .

[0022] The electrolyte circulating cooling device is mainly composed of an anodized chiller 51 , a liquid inlet pipe 52 and a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com