Ground pressure multi-directional monitoring localizable borehole stress sensor

A technology of stress sensor and ground pressure, applied in hydraulic/pneumatic metering, measurement, earthwork drilling and mining, etc., can solve problems such as single monitoring direction and inability to meet coal mine roof support monitoring, so as to increase contact area and reduce The inconvenience of carrying the data cable and the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

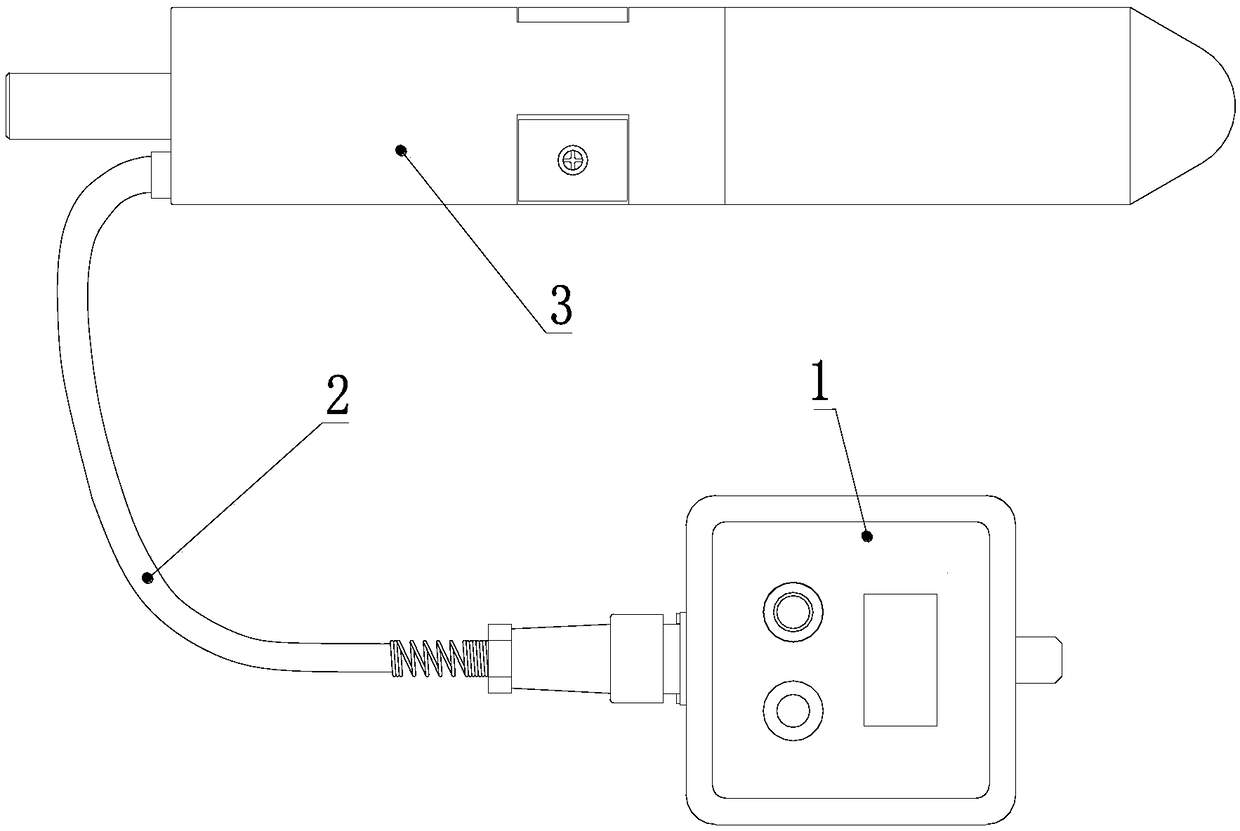

[0034] Such as figure 1 As shown, the ground pressure multi-directional monitoring can locate the borehole stress sensor, including the measuring device 3 and the measuring meter 1, and the measuring device 3 and the measuring meter 1 are connected by wired data or wireless data; the measuring device 3 and the measuring device Tables 1 are wired for data connection through data line 2. Using the data line 2 to realize wired data connection can improve the speed and accuracy of data transmission, and is suitable for short-distance data communication. When the distance between the measuring device 3 and the measuring meter 1 is too large, the measuring device 3 and the measuring meter 1 are wirelessly connected through infrared communication or bluetooth communication. The use of wireless data connection can avoid the trouble of wiring, and at the same time reduce the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com