Unhusked rice dryer

A paddy dryer and frame technology, which is applied in the direction of dryer, drying, grain drying, etc., can solve the problems of high labor intensity, rice mildew, long drying cycle, etc., and achieve simple structure of the device and avoid excessive heating , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is attached Figure 1-6 The present invention is described in detail.

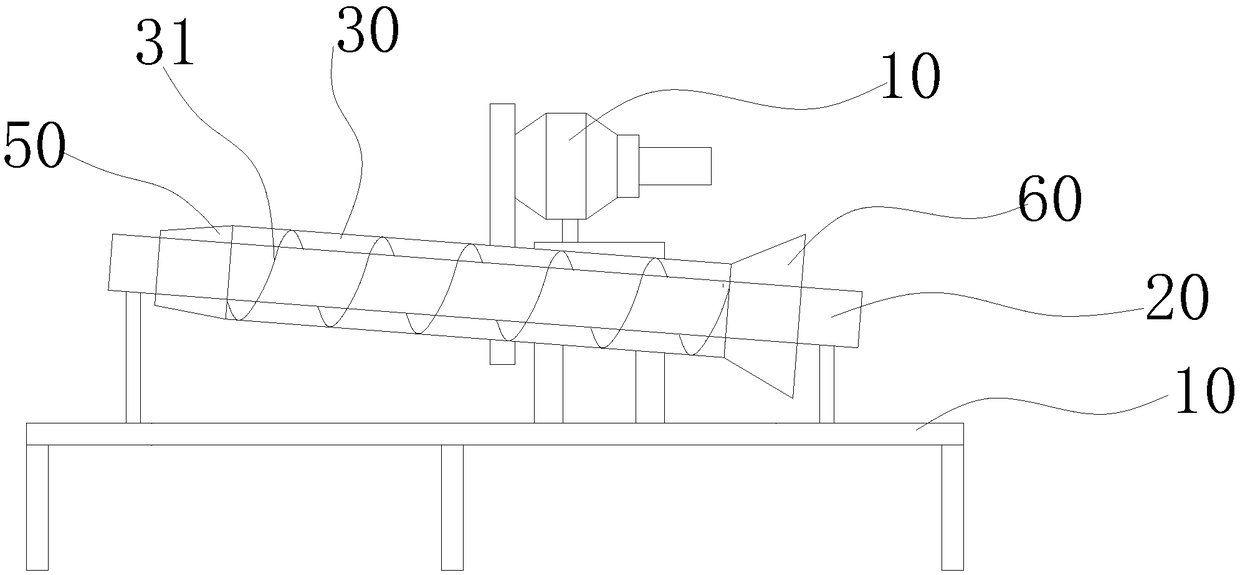

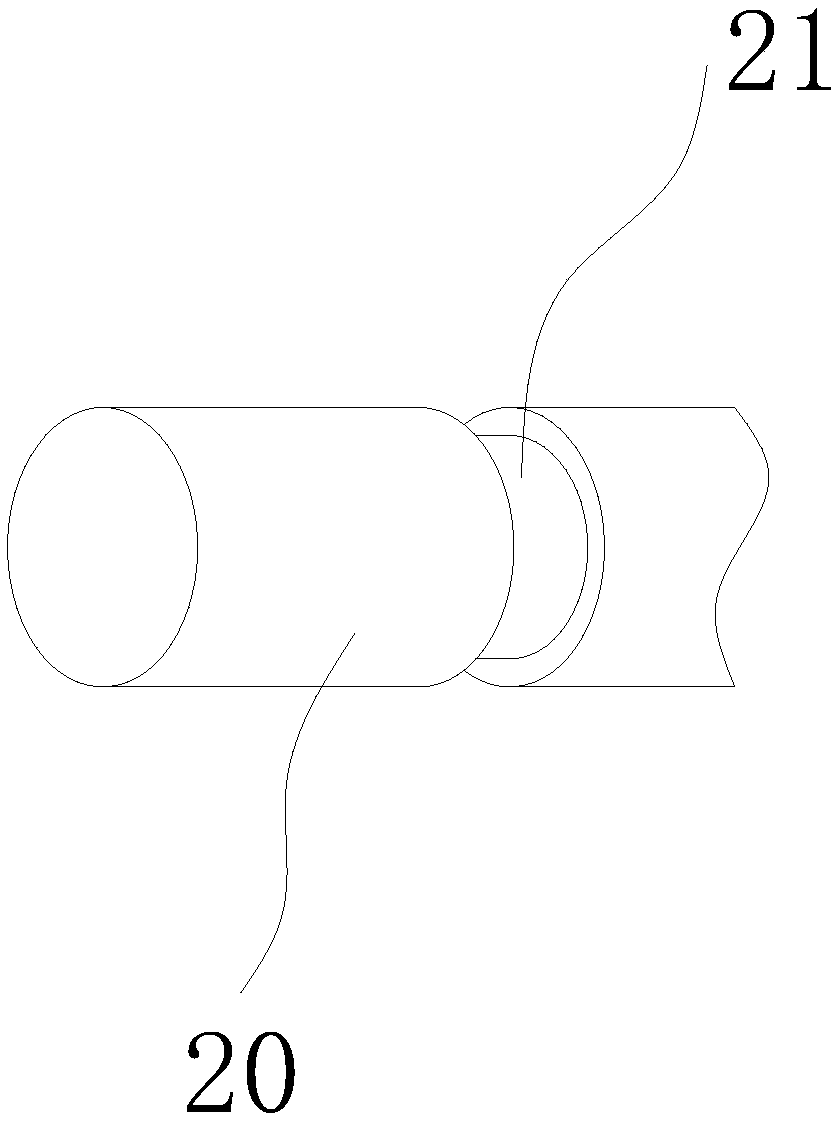

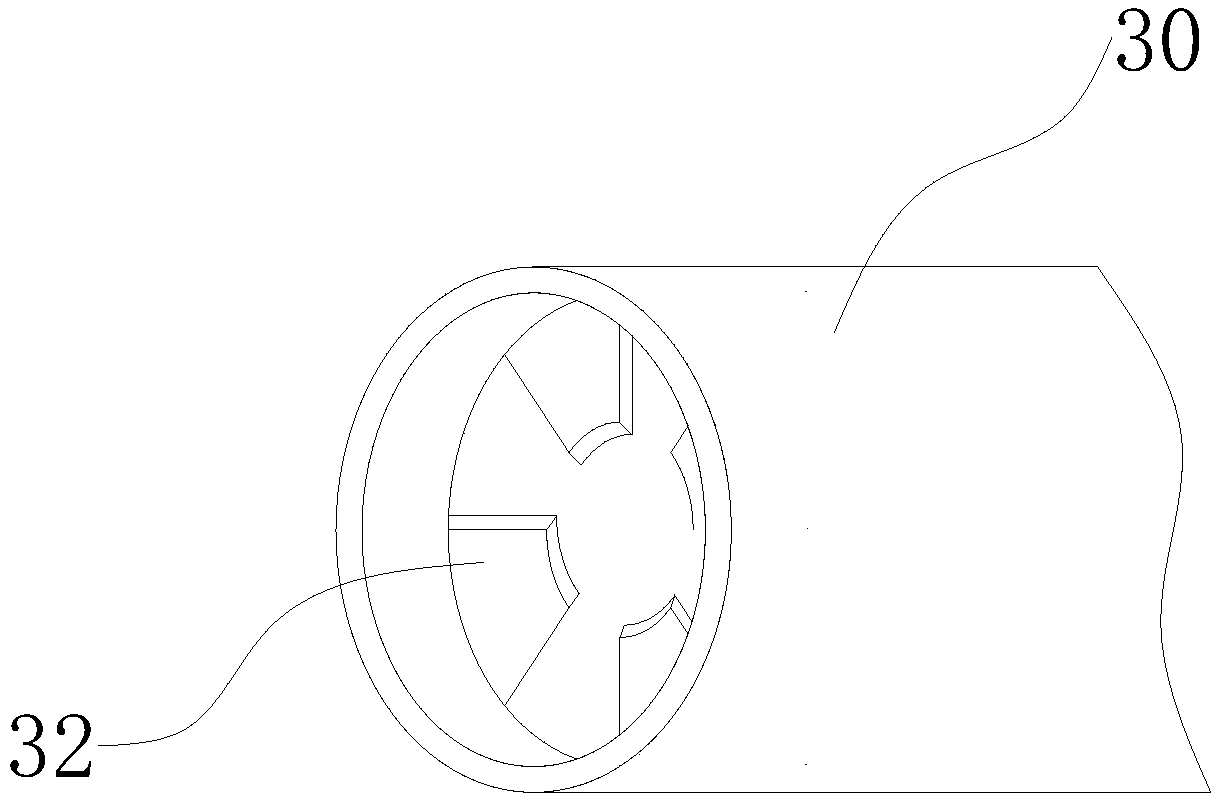

[0021] refer to Figure 1-6 , a paddy dryer, including a heating drum 20 and a drum 30 arranged on a frame 10, and a drive unit for driving the drum 30 to rotate, the heating drum 20 and the drum 30 are coaxially arranged and form a rotational fit, the heating drum 20 Cylinder cavity is communicated with heat source, and one end of cylinder 30 is provided with material inlet, and the other end of cylinder 30 is provided with discharge opening, and the sandwich cavity between cylinder wall of cylinder 30 and heating cylinder 20 constitutes the drying chamber of paddy.

[0022] During use, the heat accumulated in the heating cylinder 20 is transferred to the paddy in the cavity between the heating cylinder 20 and the drum 30 through the cylinder wall, and the drying process can be completed after the paddy is heated. In fact, when the drive unit drives the drum 30 to roll, it will driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com