Patents

Literature

31results about How to "Less yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light refection sheet, process for producing the same and molding thereof

InactiveUS20060159926A1Improve reflectivityHigh propertyDiffusing elementsSynthetic resin layered productsLight reflectionOptical transmittance

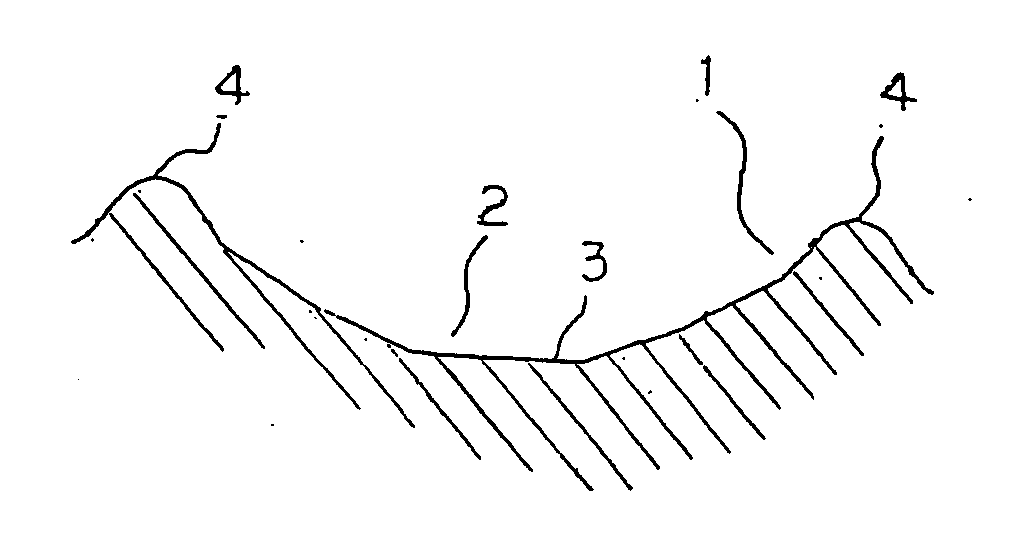

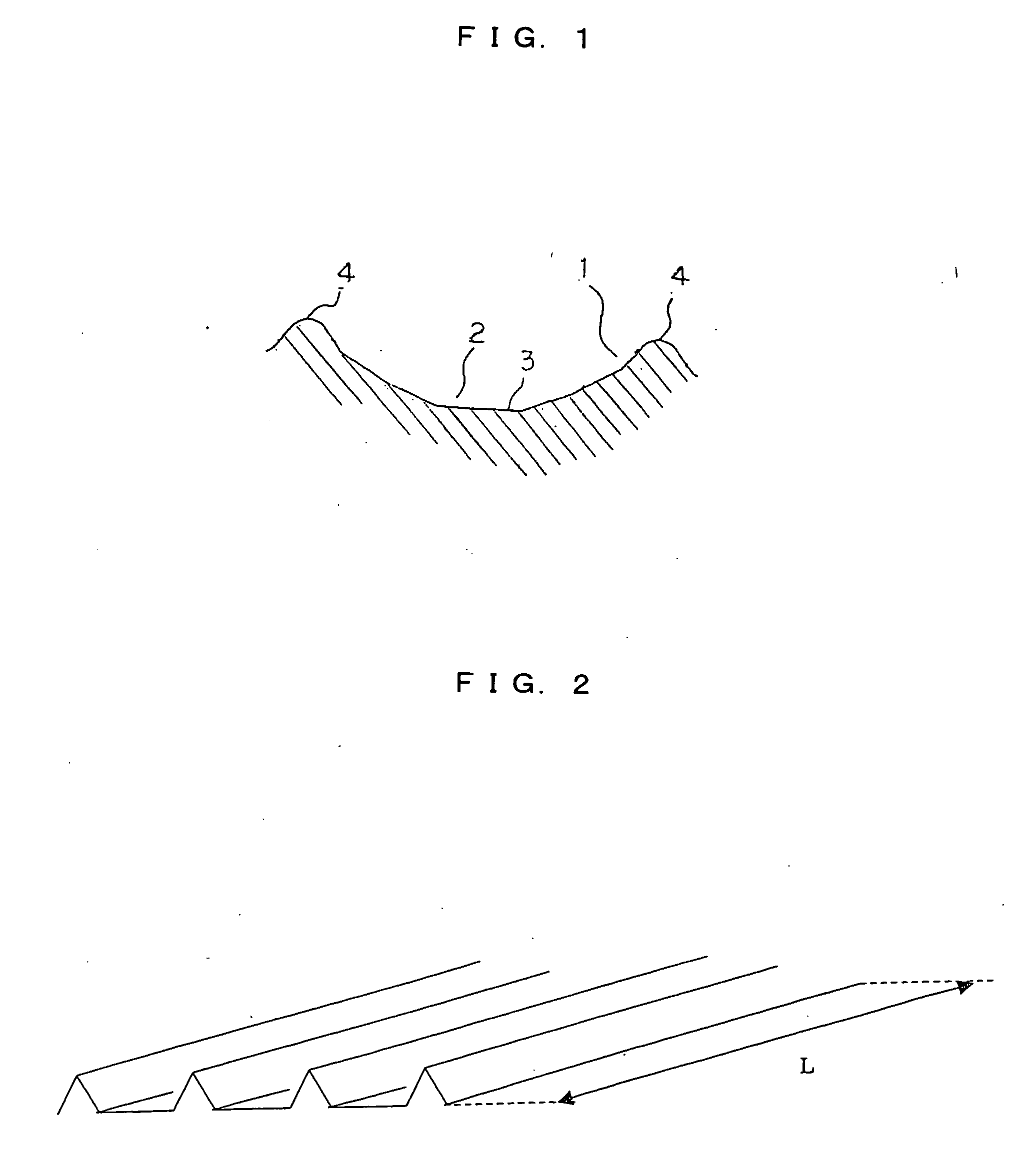

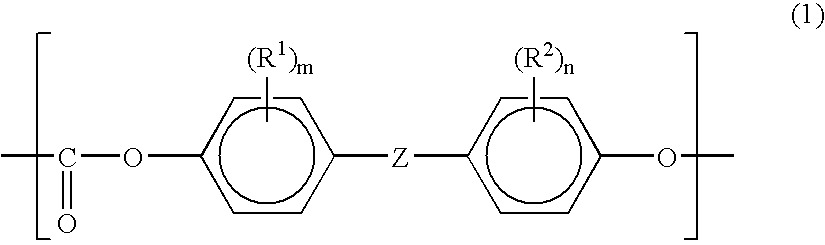

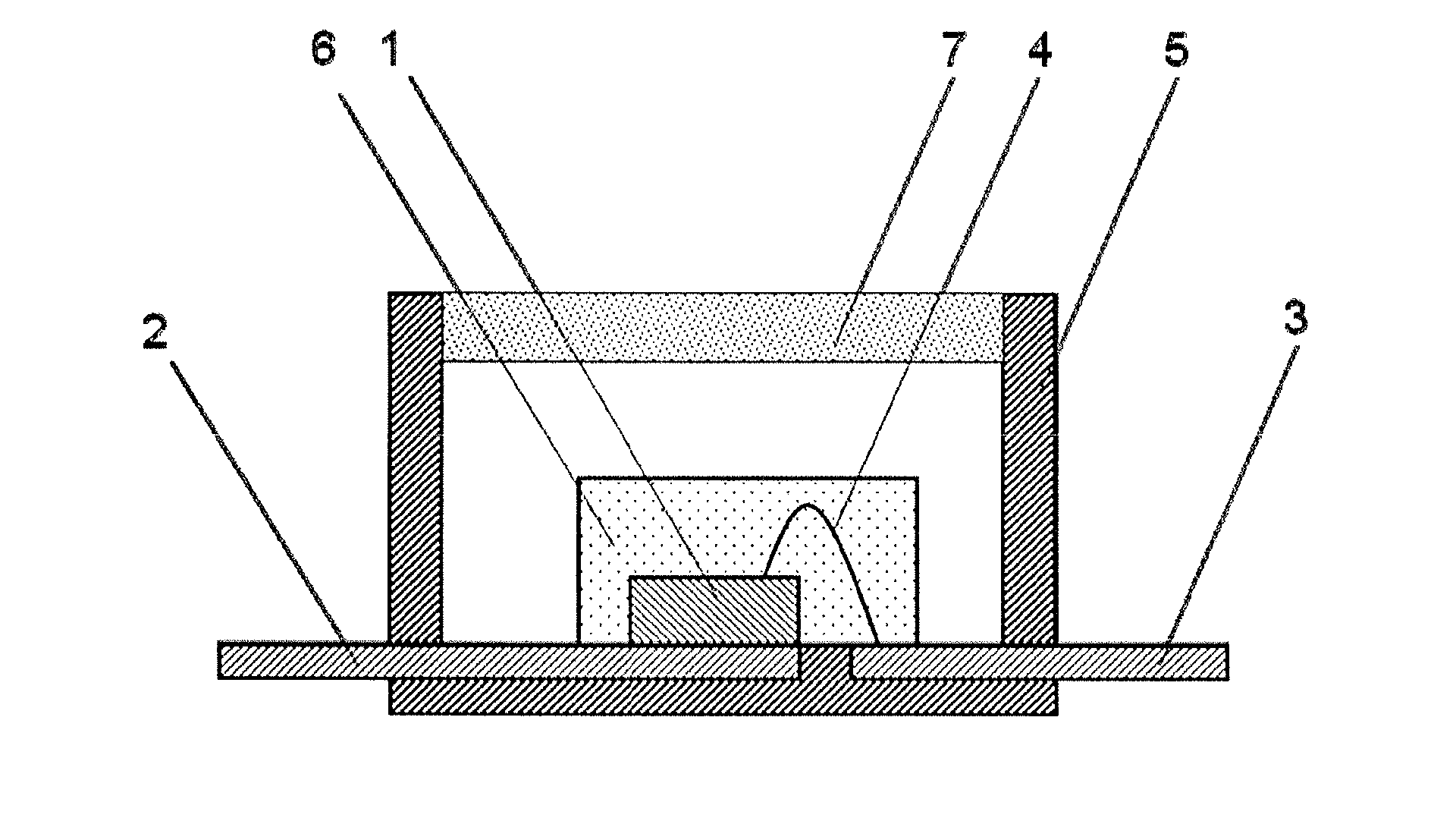

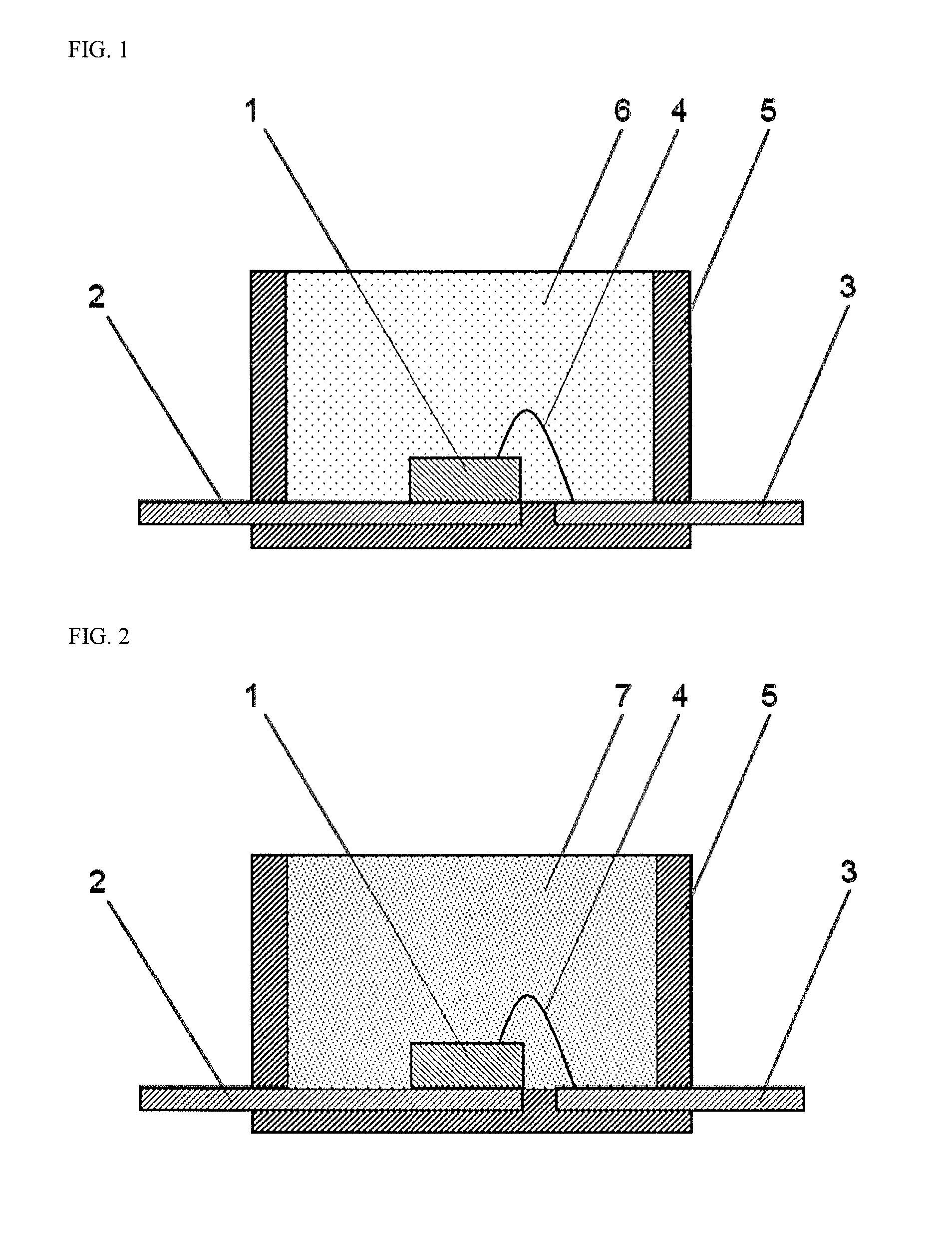

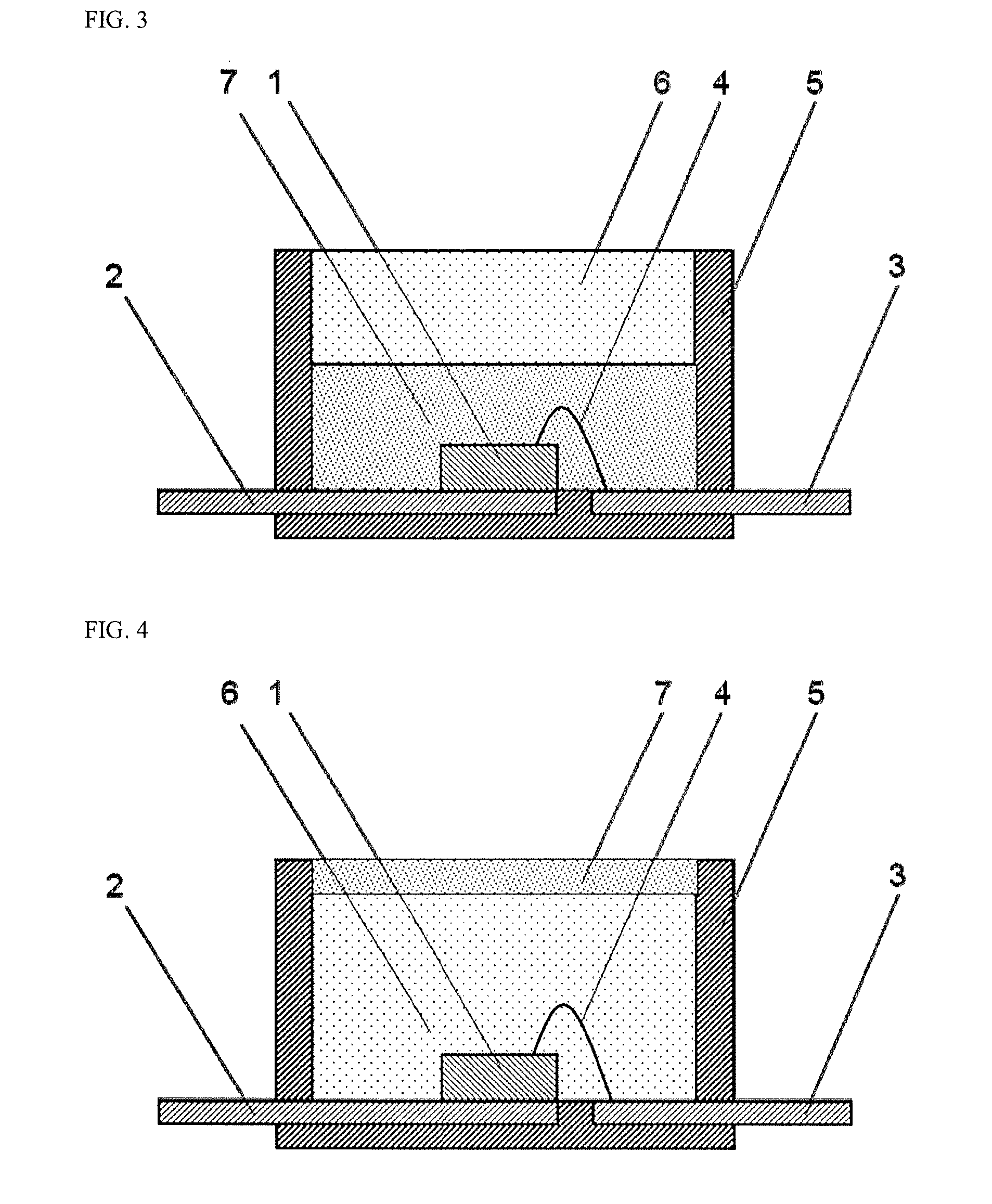

The light reflection sheet (I) of the present invention comprises a sheet having a thickness of 0.4 to 2 mm and comprising a polycarbonate resin composition containing (B) titanium oxide, and the sheet has a light reflectance of 98% or more and a light transmittance of less than 1%. It is excellent in a flame retardancy and a reflection characteristic. Also, the light reflection sheet (II) of the present invention is prepared by providing a light-fast layer which cuts or absorbs a UV ray in a thickness of 0.5 to 20 μm on at least one face of a base sheet having a thickness of 0.4 to 2 mm and comprising a PC resin composition containing a combination of 85 to 60 mass % of (A) a PC base polymer and 15 to 40 mass % of (B) titanium oxide. It is less yellowed and less reduced in a reflection characteristic even after used for a long period of time. Further, the light reflection sheet (III) of the present invention is prepared by providing a light diffusion layer which diffuses and reflects light in a thickness of 0.5 to 20 μm on at least one face of the same base sheet as in the light reflection sheet (II). It is improved in a light diffusing and reflecting property and can form a liquid crystal image plane having less luminance unevenness when it is used as a direct under type liquid crystal back light.

Owner:IDEMITSU KOSAN CO LTD

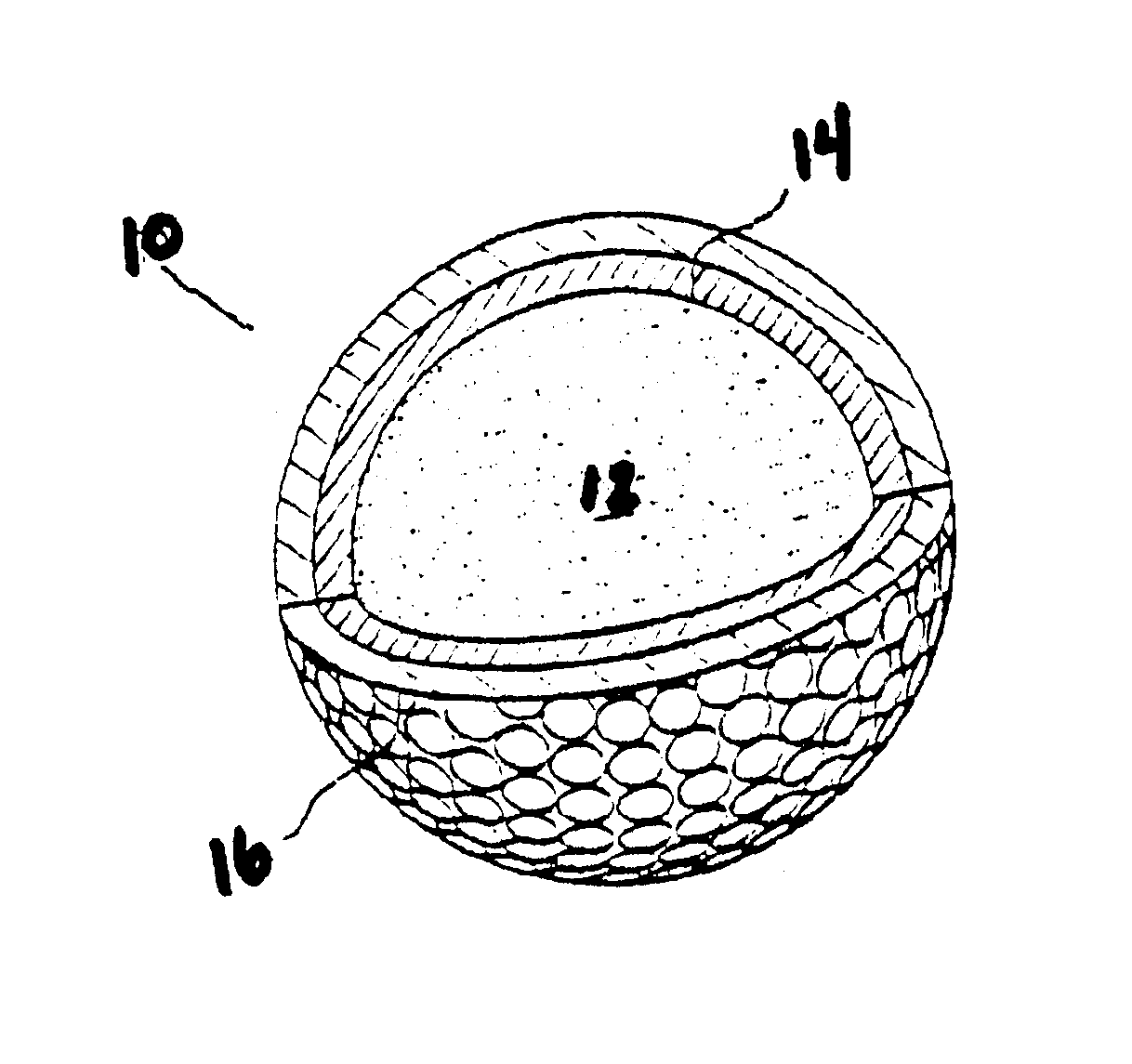

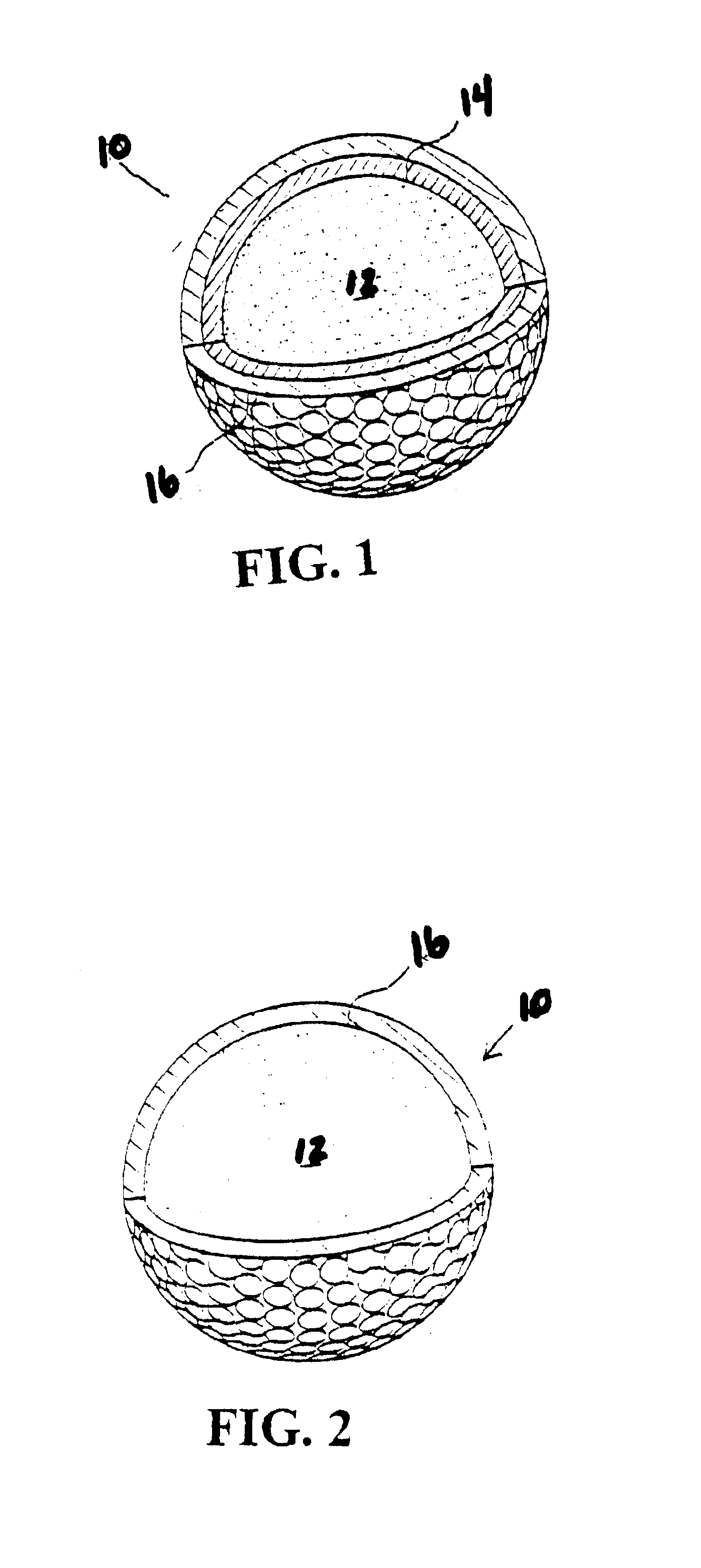

Thermosetting polyurethane material for a golf ball cover

A prepolymer blend for a thermosetting polyurethane material that allows for control of the reaction time is disclosed herein. The prepolymer blend is preferably composed of a polyurethane prepolymer and dimethyl methylphosphonate. The thermosetting polyurethane is preferably utilized as a cover for a golf ball. The cover is preferably formed over a core and boundary layer.

Owner:TOPGOLF CALLAWAY BRANDS CORP

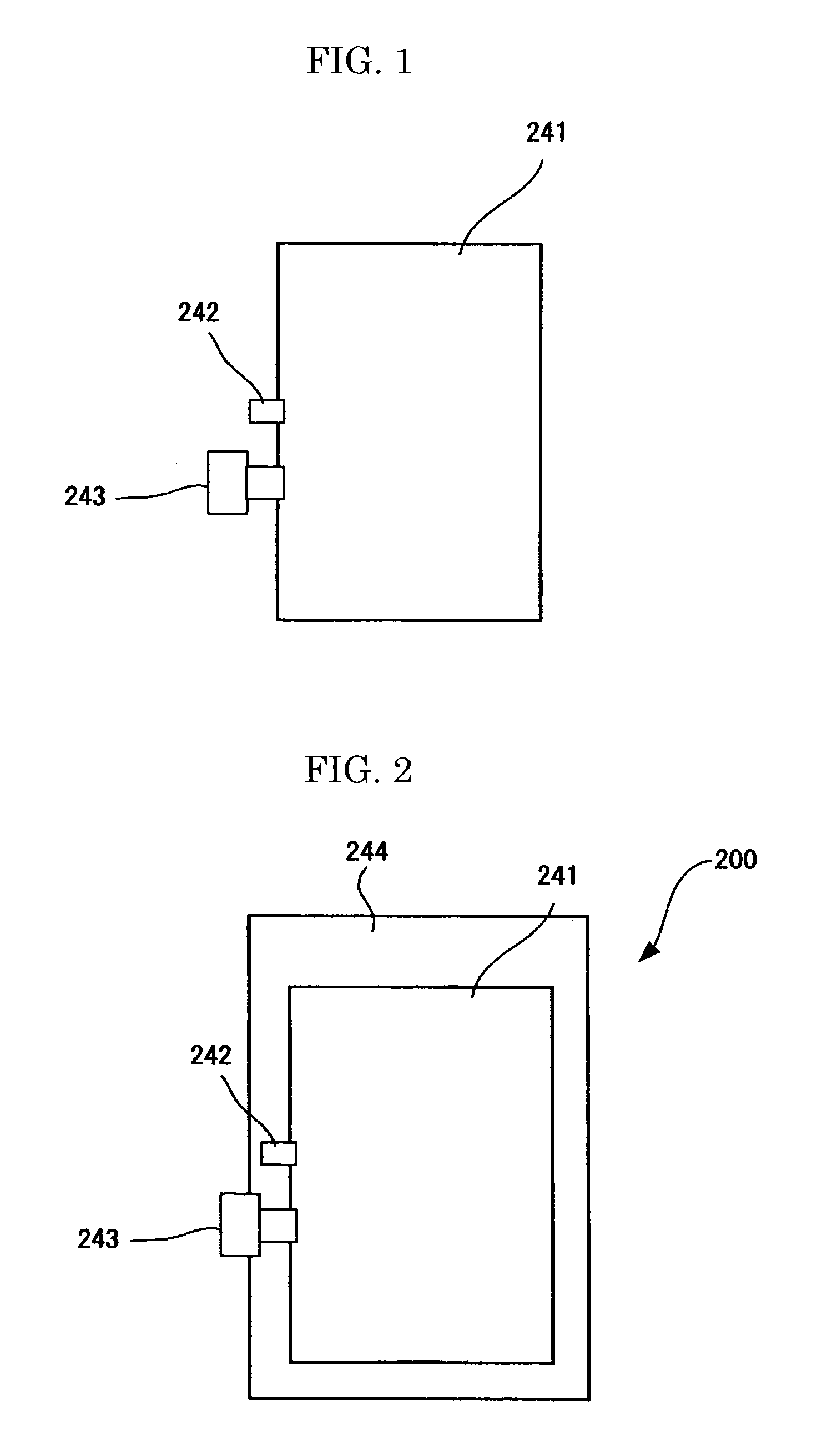

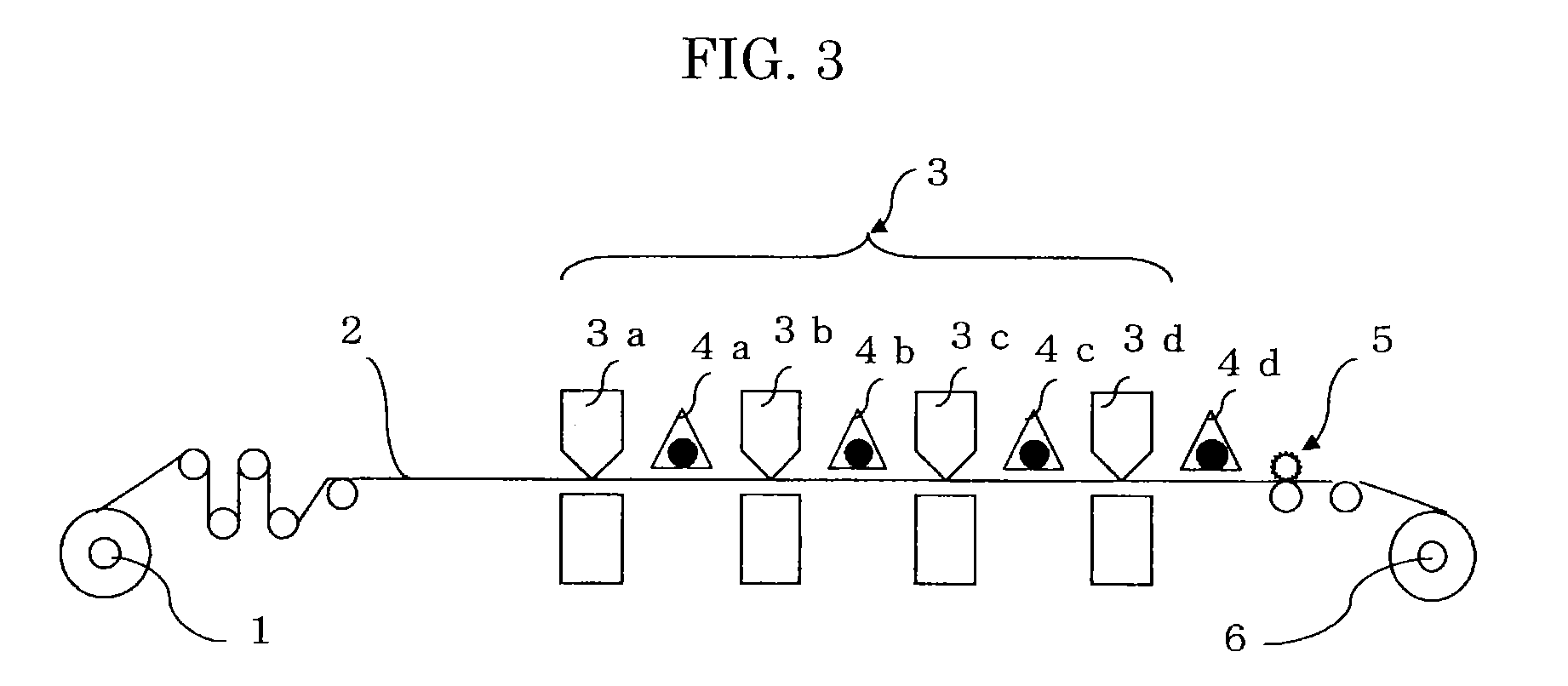

Photopolymerizable inkjet ink, ink cartridge, and inkjet recording device

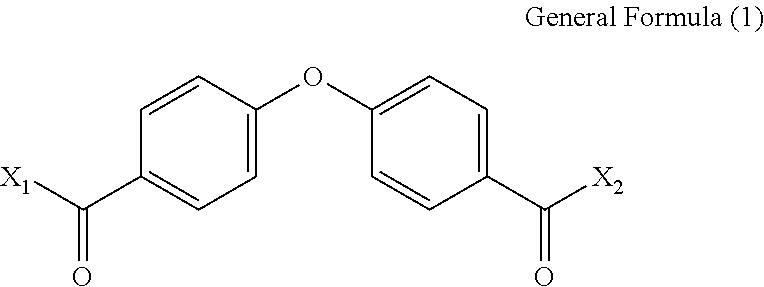

To provide a photopolymerizable inkjet ink including: diethylene glycol dimethacrylate; caprolactone-modified dipentaerythritol hexaacrylate; and a photopolymerization initiator represented by the following general formula (1):where X1 is represented by the following general formula (1-1), and X2 is represented by the following general formula (1-2):where R1 to R4 are each independently a C1-C6 alkyl group, and R1 and R2 may be linked to form a ring, and R3 and R4 may be linked to form a ring; Z1 and Z2 is —NR5R6 or OR7; R5 and R6 are each independently a C1-C6 alkyl group, and R5 and R6 may be linked to form a ring; and R7 is a hydrogen atom, a methyl group, or a trimethylsilyl group.

Owner:RICOH KK

Artificial nail composition having improved curability

InactiveUS20100008876A1High surface glossLess yellowingCosmetic preparationsToilet preparationsDouble bondMethyl group

An object of the present invention is to provide an artificial nail composition having improved curability. Another object of the present invention is to provide an artificial nail composition which causes less yellowing and has excellent internal curability.The artificial nail composition comprises:a component (a): a compound having at least one radical polymerizable unsaturated double bond in the molecule, and a component (b): a photopolymerization initiator selected from (i) an acylphosphine oxide-type photopolymerization initiator and (ii) a mixture of an acylphosphine oxide-type photopolymerization initiator and an α-hydroxyalkylphenone-type photopolymerization initiator, wherein the amount of the component (b) is 0.05 to 4.00 parts by weight with respect to 100 parts by weight of the component (a). It is preferred that the acylphosphine oxide-type photopolymerization initiator is monoacylphosphine oxide and / or bisacylphosphine oxide, and the α-hydroxyalkylphenone type polymerization initiator is 1-hydroxy-cyclohexyl-phenyl-ketone or 2-hydroxy-2-methyl-1-phenyl-propan-1-one.

Owner:SHOFU INC

(METH)acrylate composition

InactiveUS20130237660A1High whitenessLess yellowingCoatingsSemiconductor devicesMeth-Aliphatic hydrocarbon

Provided is a (meth)acrylate composition containing: (A) at least one (meth)acrylate compound selected from the group consisting of a (meth)acrylate-modified silicone oil, a (meth)acrylate having a long-chain aliphatic hydrocarbon group, and a polyalkylene glycol (meth)acrylate having number-average molecular weight of not less than 400; (B) a (meth)acrylate compound to which an alicyclic hydrocarbon group having 6 or more carbon atoms is ester-linked; (C) (meth)acrylic acid or a (meth)acrylate compound having a polar group; (D) a radical polymerization initiator; and (E) a white pigment.

Owner:IDEMITSU KOSAN CO LTD

Curable Silicone Composition, Cured Product Thereof, And Optical Semiconductor Device

ActiveUS20160194496A1Less yellowingImprove reliabilityGroup 4/14 element organic compoundsGroup 3/13 organic compounds without C-metal linkagesHydrosilylationPolymer chemistry

The present invention relates to a curable silicone composition comprising: (A) an organopolysiloxane having at least two alkenyl groups and at least one aryl group in a molecule, (B) an organopolysiloxane having at least two silicon atom-bonded hydrogen atoms in a molecule, (C) an organopolysiloxane having at least one aryl group in a molecule and containing a metal atom selected from the group consisting of V, Ta, Nb and Ce, and (D) a hydrosilylation-reaction catalyst. The present invention can provide the curable silicone composition, which does not develop a crack by thermal aging and further can form a cured material that exhibits less yellowing.

Owner:DOW TORAY CO LTD +1

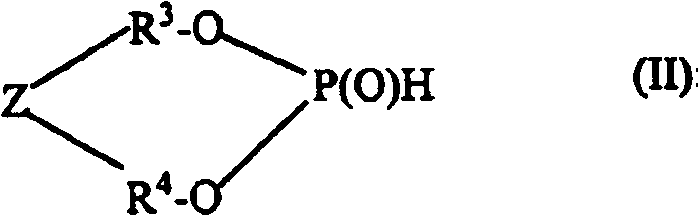

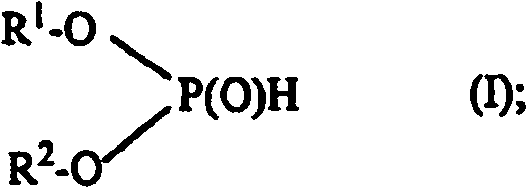

Fatliquoring agents for the flame-retardant treatment of leather

InactiveUS20080104766A1Extended shelf lifeHigh strengthTanning treatmentPre-tanning chemical treatmentOrganic phosphorusTissue skin

The present invention relates to fatliquoring agents for leathers, skins or hides, which contain neutral halogen-free organic phosphorus compounds, and the use of such fatliquoring agents for the flame-retardant treatment of leather and a process for fatliquoring in the production of flame-retardant leather, skin or hides.

Owner:LANXESS DEUTDCHLAND GMBH +1

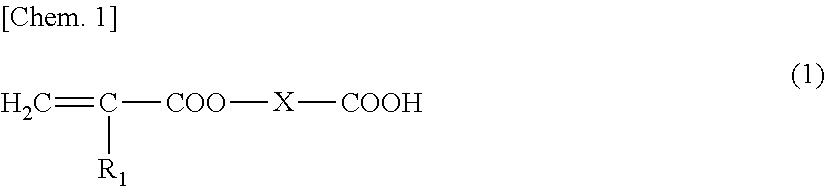

Active energy ray-curable composition for flooring materials and installation method therefor

InactiveUS20160333131A1Improves stain resistanceImprove stabilityCoatingsFlooringPolymer scienceCarbamate

Provided are an active energy ray-curable composition fox flooring materials, which is unlikely to cause a curing defect between a cured portion and an uncured portion even when a movable curing device having a light source is used is unlikely to cause yellowing attributable to exposure to natural light for a long period of time, and exhibits a high re-coatability, while exhibiting conventional physical performance, and a construction method therefor. Further, also provided are an active energy ray-curable composition for antibacterial flooring materials, which has antibacterial properties, and a construction method therefor. The active energy ray-curable composition for flooring materials is formed by appropriately applying a specific carboxyl group-containing active energy ray-polymerizable compound, a specific urethane oligomer, a specific hyperbranched oligomer, specific polyfunctional acrylate, and a specific photopolymerization initiator in combination.

Owner:DAINIPPON INK & CHEM INC

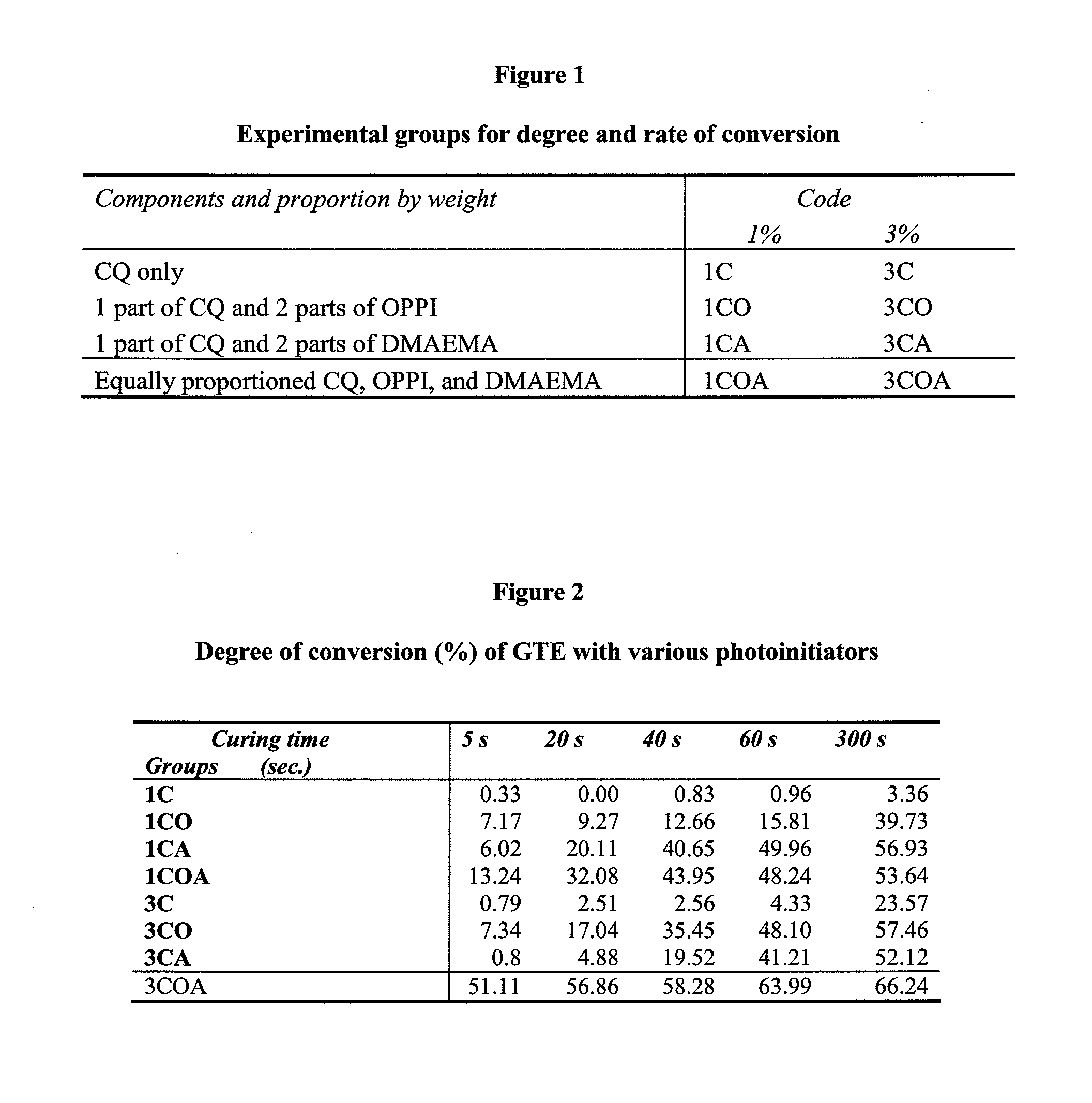

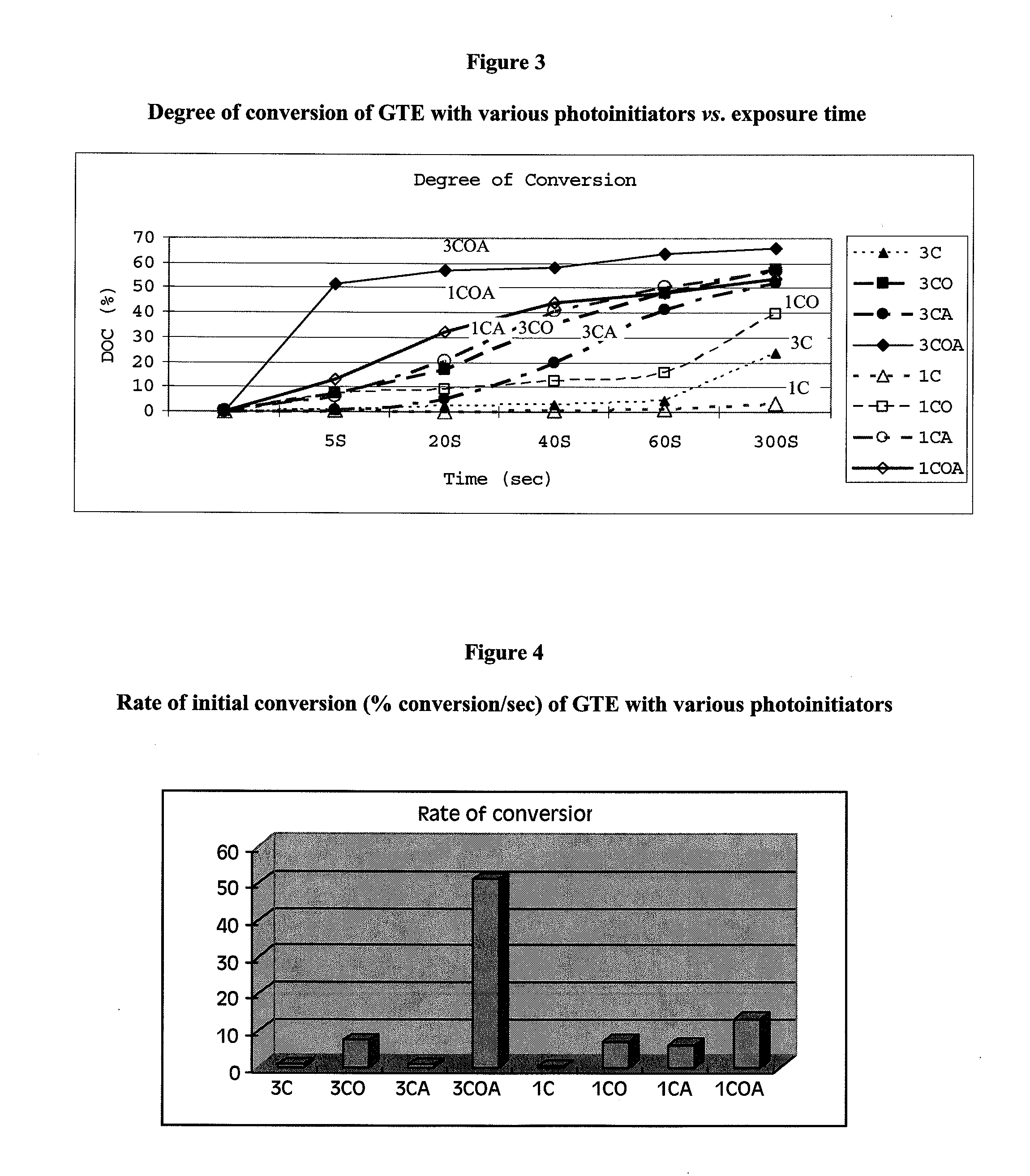

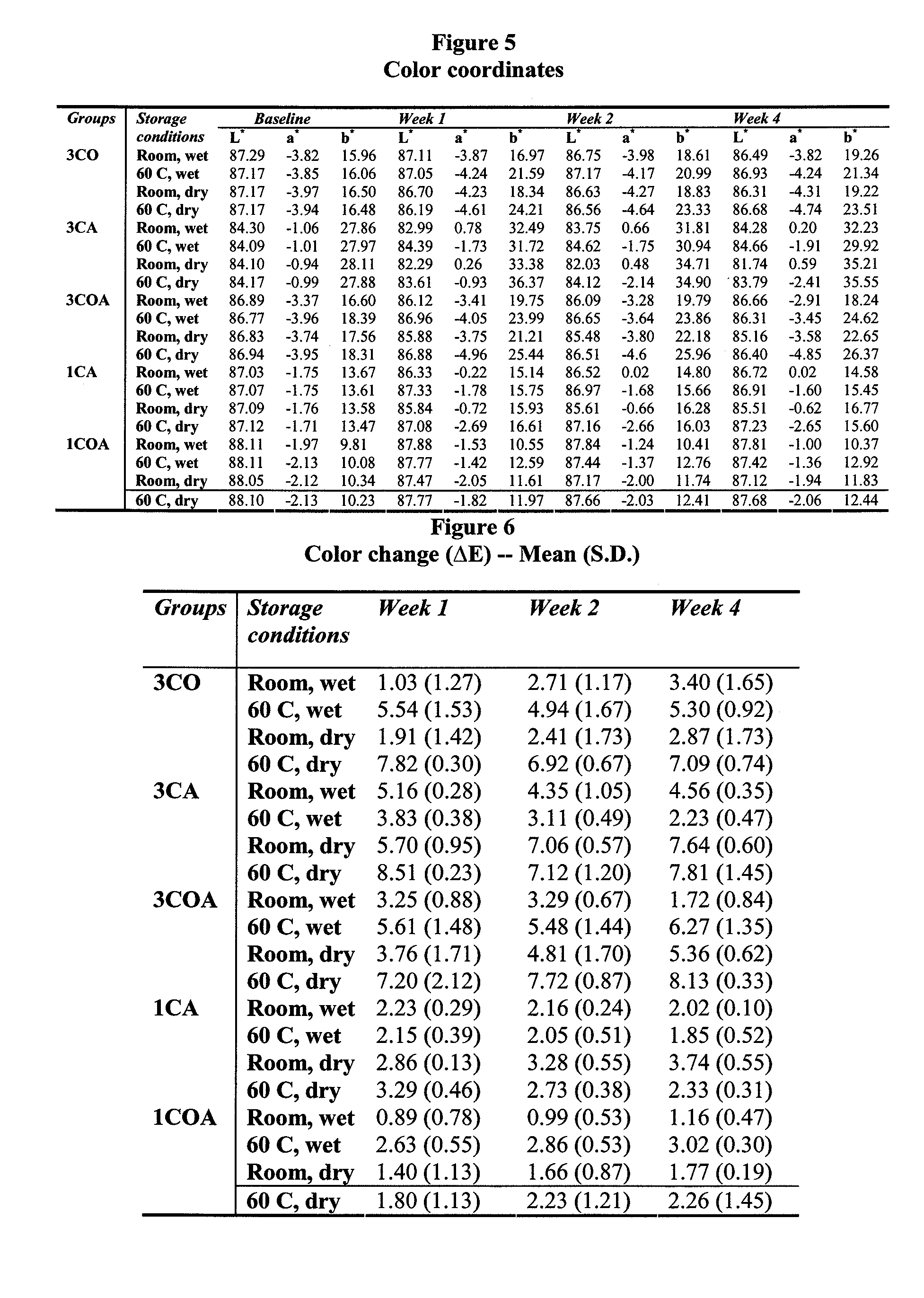

Light- and Dual-Cure Dental Resins and Adhesives With Increased Cure and Color Stability and Low Color

InactiveUS20110200973A1Low color requirementHigh degree of curingImpression capsTeeth fillingDual curingLow shrinkage

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Modified pearl pigment and its production

InactiveUS20090038513A1Change resistanceIncrease resistancePigment preparation by wet methodsOrganic dyesPolyolefinAntioxidant

The invention relates to a modified pearlescent pigment and its production process by post-coating. The pigment includes a sheet substrate, titanium dioxides coated on the substrate and hydrates of metal phosphate(s) and metal oxide(s) on the titanium dioxide coating. This pigment could keep color stable during its use and exhibit excellent discoloration resistance caused by ultraviolet as well as prevent yellowing during its use in use polyolefin compositions containing antioxidant.

Owner:LIN YIZHONG +1

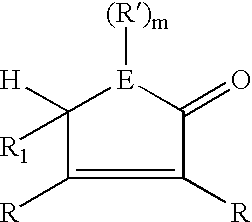

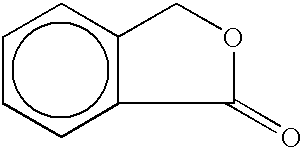

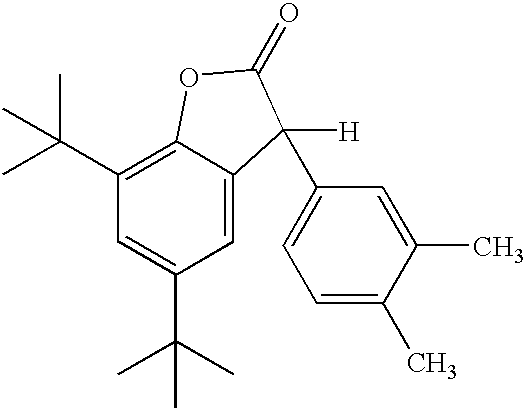

Inhibiting polymer oxidation using non-phenolic antioxidants

The oxidation of a polymer is inhibited by adding to the polymer about 0.005 to about 10 phr of an antioxidant having (in non-polymeric form) the general formulaThe polymer can be poly(vinylchloride), a polycarbonate, a polyether, polyethylene, polypropylene, or a mixture thereof when the antioxidant is not phthalide and can be poly (vinylchloride), a polycarbonate, a polyether, or a mixture thereof when the antioxidant is phthalide. In the formula, E is O, S, or N, R1 is H, R′, OR′, SR′, OP(R′)2, COR′, each R is independently selected from R1, alkylenyl from C1 to C12, aminoalkyl from C1 to C12, and hydroxyalkyl from C1 to C12, R′ is alkyl from C1 to C12 or aryl, alkylaryl, or aralkyl from C6 to C12, R″ is G, GO, GS, GNH, NHG, NHGO, NHGNH, NHGS, OG, OGO, OGNH, OGS, SGO, SGNH, or SGS, G is aklkylenyl from C1 to C12, arylenyl from C6 to C12, alkylarylenyl from C7 to C12, or arylalkylenyl from C7 to C12, m is 0 if E is O or S and is 1 if E is N, and two R groups can join from an alicyclic ring or an aromatic ring or an R group and an R1 group can join to form an alicyclic ring.

Owner:PANASONIC HEALTHCARE HLDG CO LTD

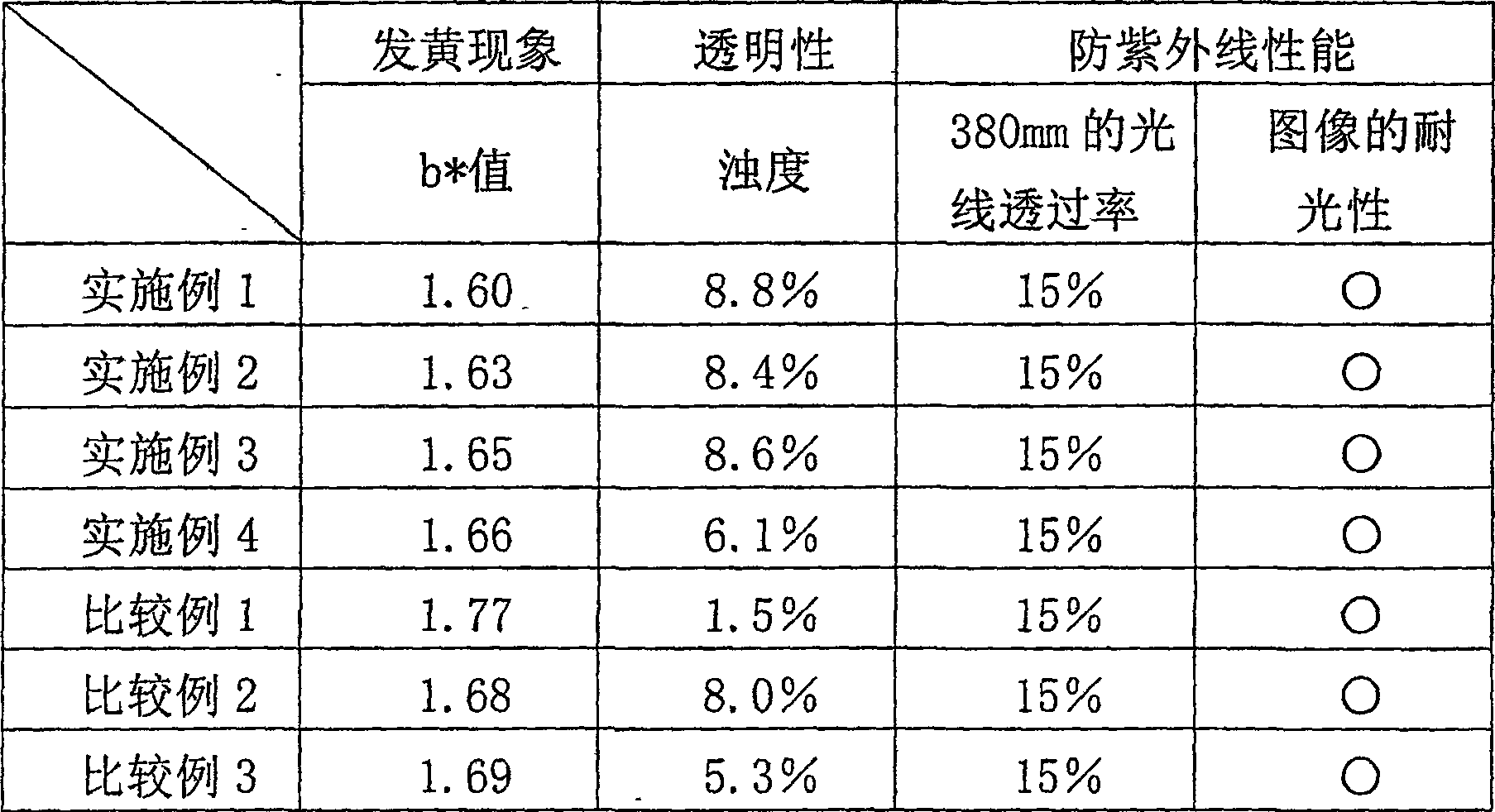

Surface protective sheet

InactiveCN1938155AImproves UV protectionImprove performanceSynthetic resin layered productsUv absorberUltraviolet protection

Disclosed is a surface protective sheet with less tinge of yellow which is excellent in ultraviolet protection. Specifically disclosed is a surface protective sheet having an ultraviolet protective layer on at least one side of a plastic film. The ultraviolet protective layer is composed of an ultraviolet absorbent, an ionizing radiation curable resin composition and spherical particles having an average particle size of 1-20 mum, and the spherical particles are contained in the ultraviolet protective layer in an amount of 0.4-3 weight%. Preferably, the ultraviolet protective layer further contains 0.01-1 weight% of organopolysiloxane.

Owner:KIMOTO CO LTD

(METH)acrylate composition

ActiveUS20150322233A1High whitenessLess yellowingCoatingsSemiconductor devicesMethacrylatePolymer science

Provided is a (meth)acrylate composition containing: (A) at least one (meth)acrylate compound selected from the group consisting of a (meth)acrylate-modified silicone oil, a (meth)acrylate having a long-chain aliphatic hydrocarbon group, and a polyalkylene glycol (meth)acrylate having number-average molecular weight of not less than 400; (B) a (meth)acrylate compound to which an alicyclic hydrocarbon group having 6 or more carbon atoms is ester-linked; (C) (meth)acrylic acid or a (meth)acrylate compound having a polar group; (D) a radical polymerization initiator; and (E) a white pigment.

Owner:IDEMITSU KOSAN CO LTD

Low temperature seedling hardening method for psammosilene tunicoides tissue culture seedling

InactiveCN105706723AImprove stress resistanceHigh transplant survival ratePlant cultivationCultivating equipmentsDisinfectantRoot rot

The invention relates to a low temperature seedling hardening method for a psammosilene tunicoides tissue culture seedling. The method comprises the steps: transferring psammosilene tunicoides bottled seedling into a seedling hardening culture chamber, and fumigating in a closed manner for 20 min by virtue of potassium permanganate and formaldehyde; culturing the tissue culture seedling for 7 days in an environment with good ventilation at the ambient temperature of 16 to 18 DEG C, the light intensity of 1800 to 2000 Lx and the lighting time of 12 h / d; adjusting the temperature to 11 to 13 DEG C, adjusting the light intensity to 1500 to 1800 Lx, continuously culturing for 14 days, then taking out the psammosilene tunicoides tissue culture seedling by virtue of tweezers, soaking in a 800-time carbendazim disinfectant for 2 h, air-drying, and then transplanting the psammosilene tunicoides tissue culture seedling into a seedling hardening matrix. On the basis that the content of soluble sugar of plants is increased in a low temperature environment, the water content is reduced, the enzyme activity is reduced and air holes are closed, the stress resistance of the plant is finally improved, the rejuvenation period is obviously shortened after the seedling is transplanted, and the probability of the plant infected by root rot and stem rot is reduced, so that the transplanting survival rate is increased to 95 percent or more, and the seedling hardening transplanting survival rate is greatly increased.

Owner:SOUTHWEST FORESTRY UNIVERSITY +1

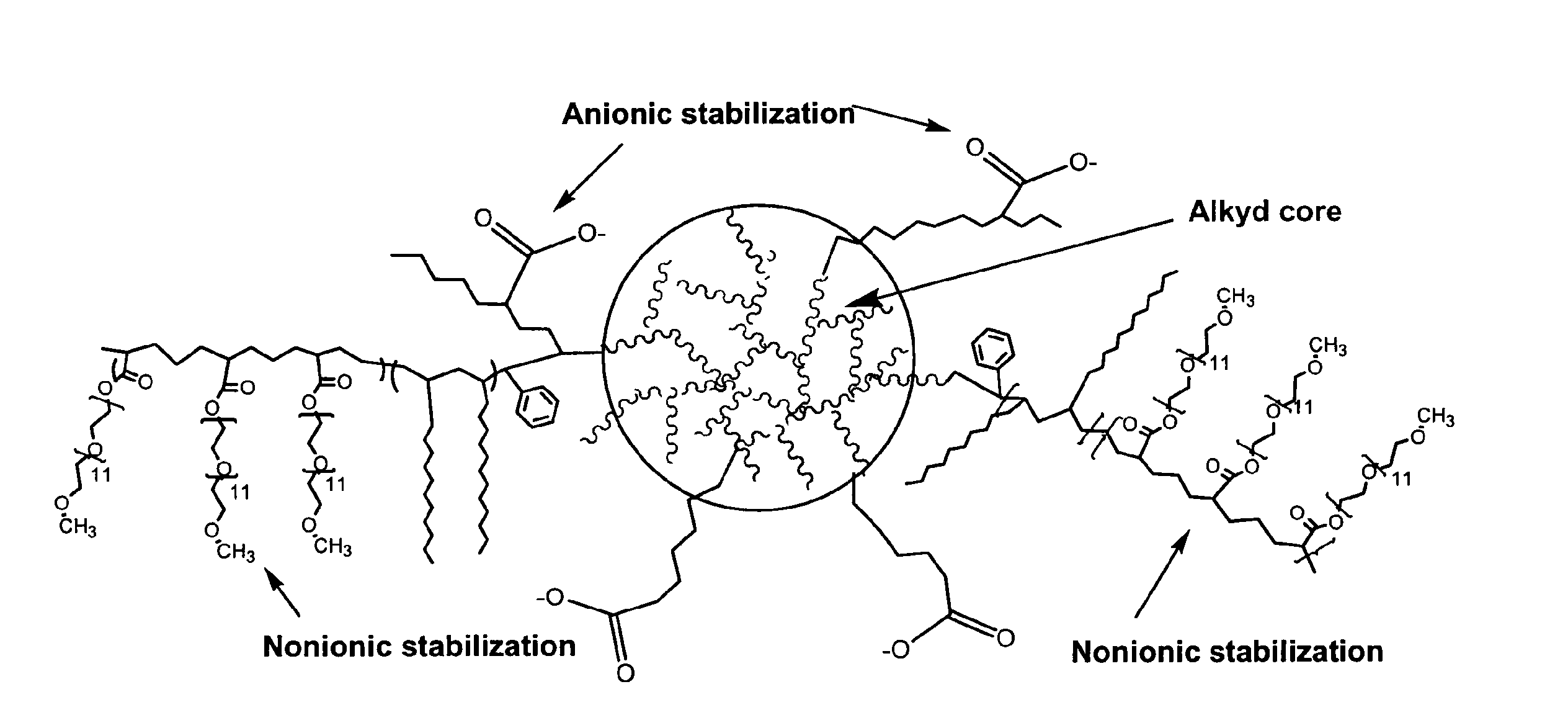

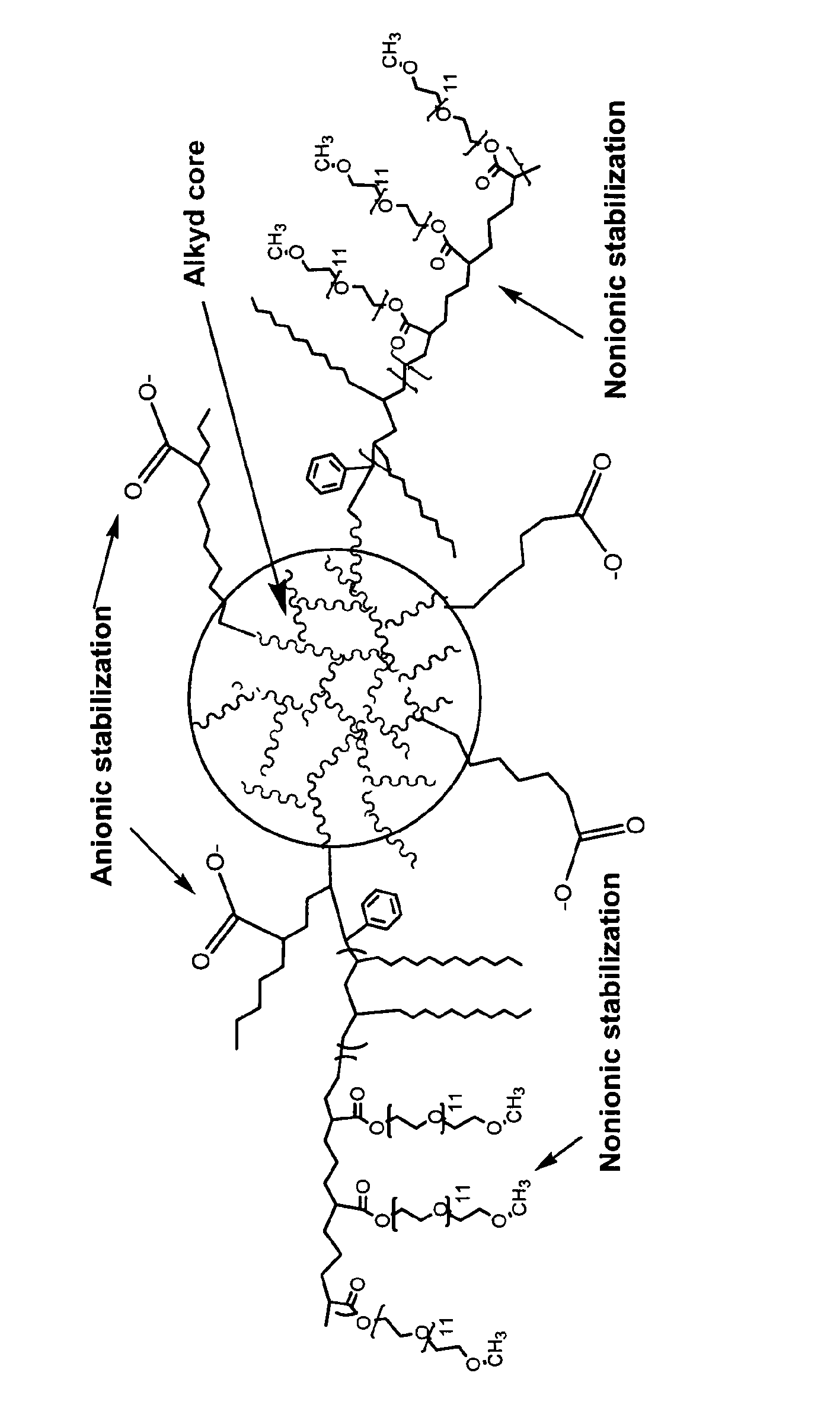

Waterborne polymeric dispersions

ActiveUS8519026B2Good dispersionImprove stabilityGranular deliveryEmulsion paintsAdhesiveHydrophobic polymer

A polymeric composition for making aqueous polymeric dispersions, comprises hydrophilic macromonomer (I), hydrophobic polymer (II) and bridging monomer (III), wherein the hydrophilic macromonomer (I) and hydrophobic polymer (II) are grafted together in the presence of bridging monomer (III) and the hydrophilic macromonomer (I) has a structure according to formula (1): R—C(X)═CH2, wherein R is a polymeric group and X is a radical stabilizing group. The aqueous polymeric composition is used for making a coating composition, a printing ink, an adhesive, a sealant or caulking material.

Owner:ALLNEX NETHERLANDS BV

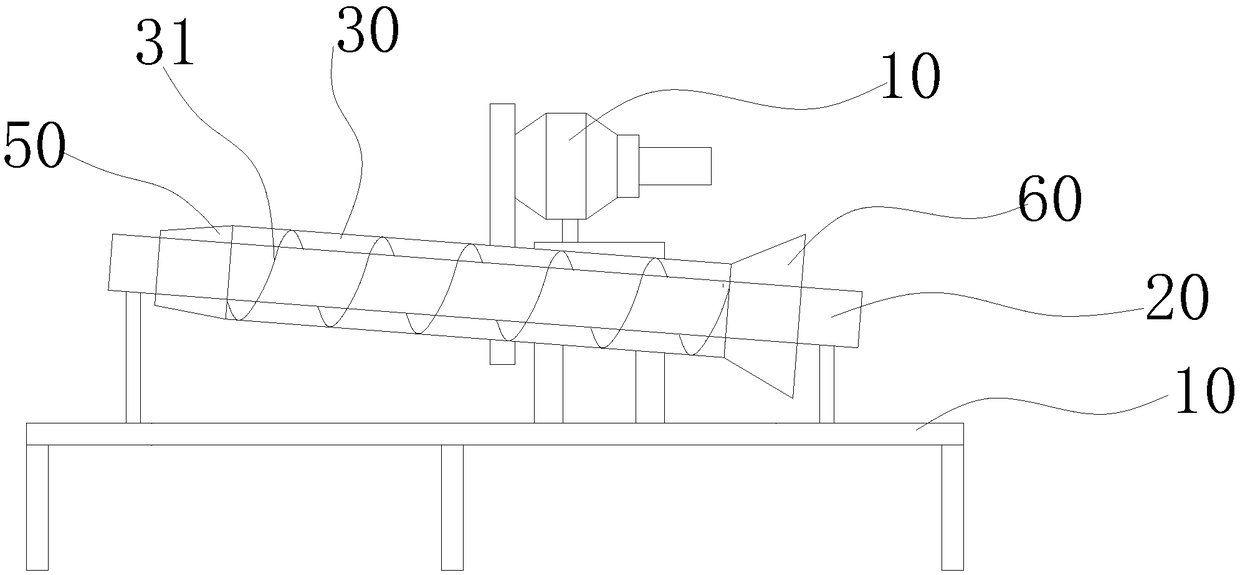

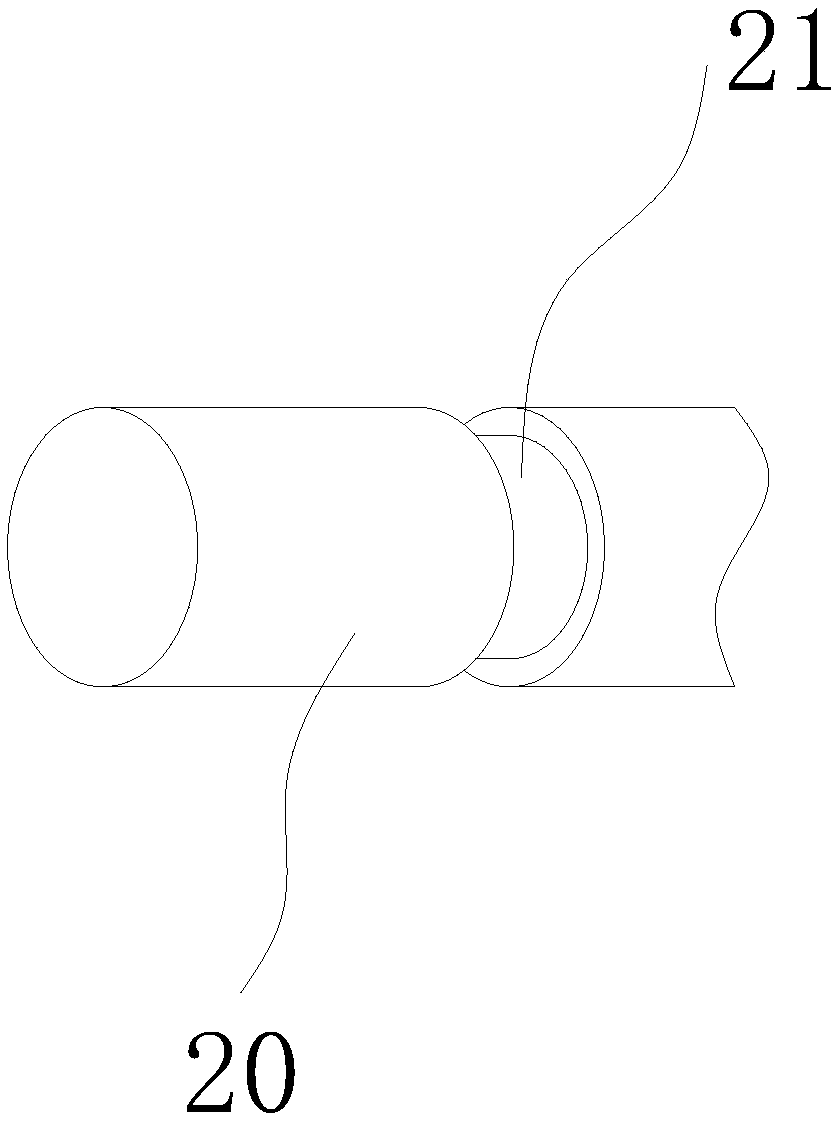

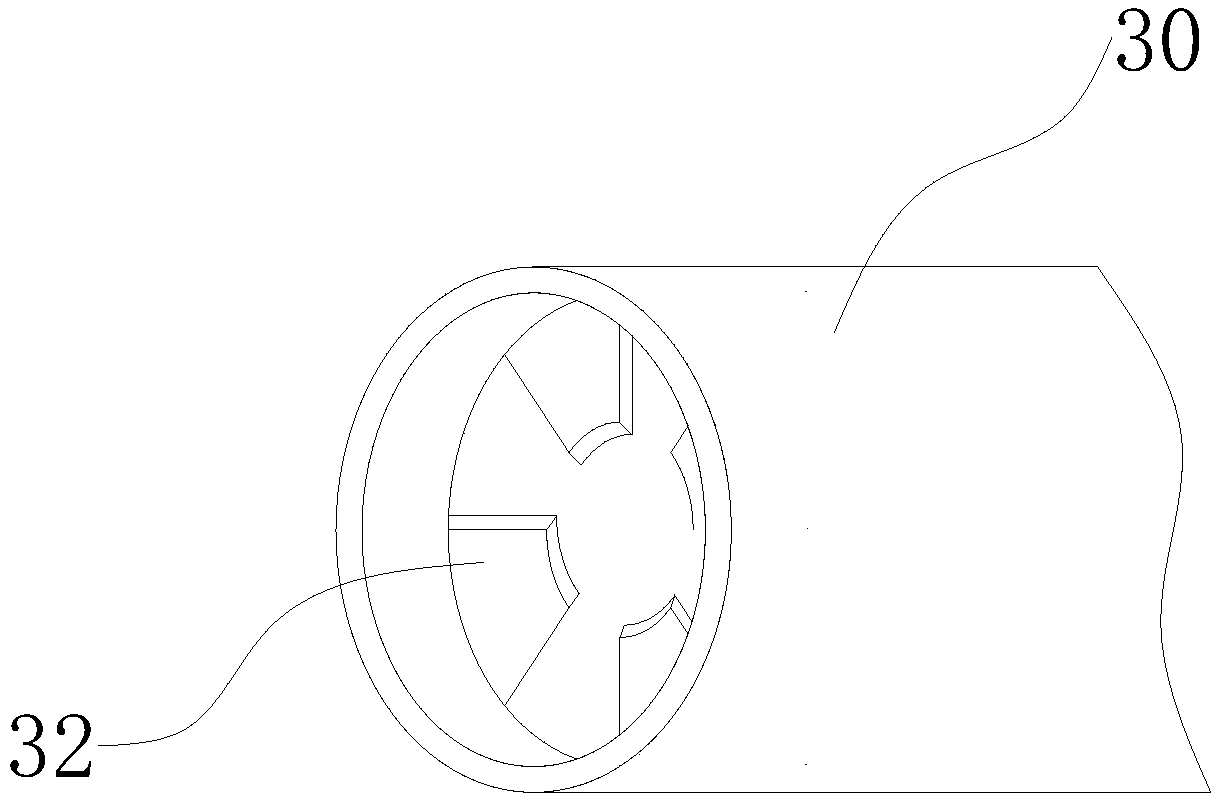

Unhusked rice dryer

InactiveCN109114914AReduce crackingReduce broken rice rateDrying machines with non-progressive movementsDrying solid materialsPulp and paper industryMechanical equipment

The invention relates to the technical field of agricultural mechanical equipment, in particular to an unhusked rice dryer. The unhusked rice dryer comprises a heating barrel, a roller and a drive unit, wherein the heating barrel and the roller are arranged on a rack, and the drive unit drives the roller to rotate. The heating barrel and the roller are arranged coaxially and are in running fit. Abarrel cavity of the heating barrel communicates with a heat source. A feeding opening is arranged at one end of the roller, and a discharging opening is arranged at the other end of the roller. An unhusked rice drying chamber is formed by a clamp cavity between the roller and the barrel wall of the heating barrel. The unhusked rice dryer has the advantages that the unhusked rice dryer is provided, the heating barrel heats unhusked rice in the roller, the unhusked rice repeats turnover action in the drying process, excessive heating is avoided, and it can be guaranteed that drying is achievedsufficiently; and few cracking phenomena of the unhusked rice dryer during later processing happen, the rice breaking rate is low, and few yellowing phenomena happen. In addition, the dryer is simplein structure, the size can be determined according to actual application conditions, and the unhusked rice dryer is suitable for household operation and also suitable for the drying requirement of large farmlands and is wide in application range.

Owner:JIXI YUANDAO AGRI IND TECH

Surface active composition containing alcoholethoxy sulfate for use in laundry detergents and process for making it

InactiveUS20060183655A1Less yellowingGood whiteness maintenanceNon-ionic surface-active compoundsSulfonic acid preparationSulfationAlcohol

The development and method for the production of an alkyl ethoxysulfate and alkyl ethoxysulfate / ethoxylated alcohol binary surfactant system using a sulfation process. A process for producing an alkyl ethoxysulfate / ethoxylated alcohol binary surfactant system additionally comprises the step of combining the resultant alkyl ethoxysulfate with the ethoxylated alcohol feed stream.

Owner:DIAL CORPORATION

Vinyl alcohol polymer-containing coating agent for paper and paper and thermal paper coated with the coating agent

InactiveUS20100196731A1Improve waterproof performanceLess yellowingSynthetic resin layered productsCellulosic plastic layered productsGramEthylene urea

A vinyl alcohol polymer-containing coating agent for paper is provided that allows a curing step to be omitted after a paper surface is coated therewith and makes it possible to form a layer (for example, a coating layer or a color developing layer) that is excellent in water resistance and is subjected to less yellowing over time. It is an aqueous composition containing a vinyl alcohol polymer (A) in which the content X of vinyl alcohol units (mol %) and the content Y of ethylene units (mol %) satisfy a formula X+0.2Y>95, where X<99.9 and 0≦Y≦10, and an addition condensate (B) between ethylene urea and glyoxal in which the content of terminal aldehyde groups per gram of solid content is 1.2 to 3.0 (mmol), wherein the solid content weight ratio between the vinyl alcohol polymer (A) and the addition condensate (B) is in a range of (A):(B)=99:1 to 50:50.

Owner:KURARAY CO LTD

Styrene-acrylonitrile copolymer foam with minimal yellowing

ActiveUS9051438B2Reduce concentrationLess yellowingPeptide preparation methodsAcrylonitrileOrganic chemistry

Prepare polymeric foam articles having low yellowing using a styrene-acrylonitrile copolymer that contains less than 145 weight-parts acrylonitrile dimer and less than 8,500 weight-parts acrylonitrile trimer per million weight parts acrylonitrile copolymer.

Owner:DOW GLOBAL TECH LLC

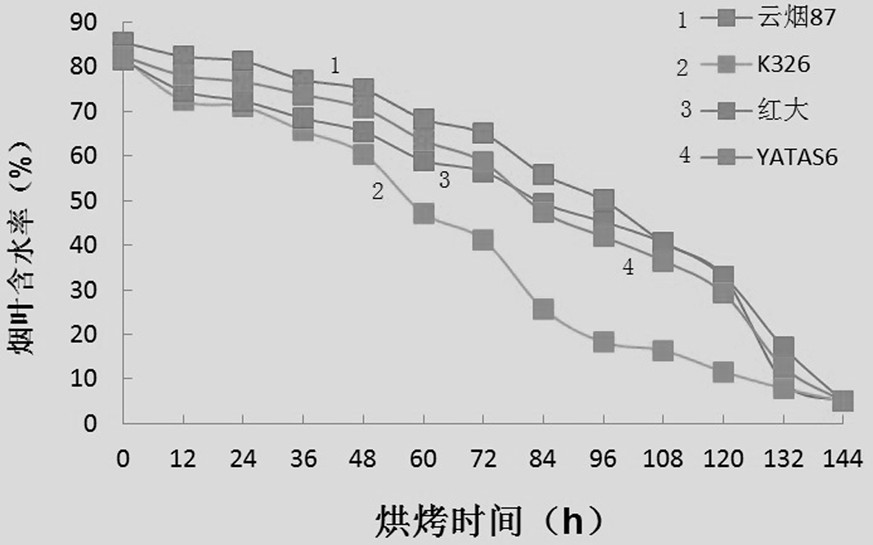

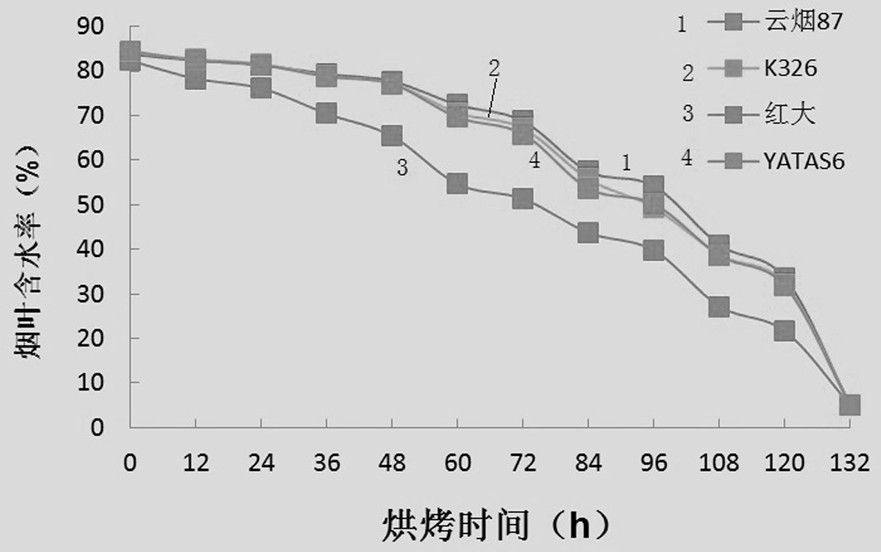

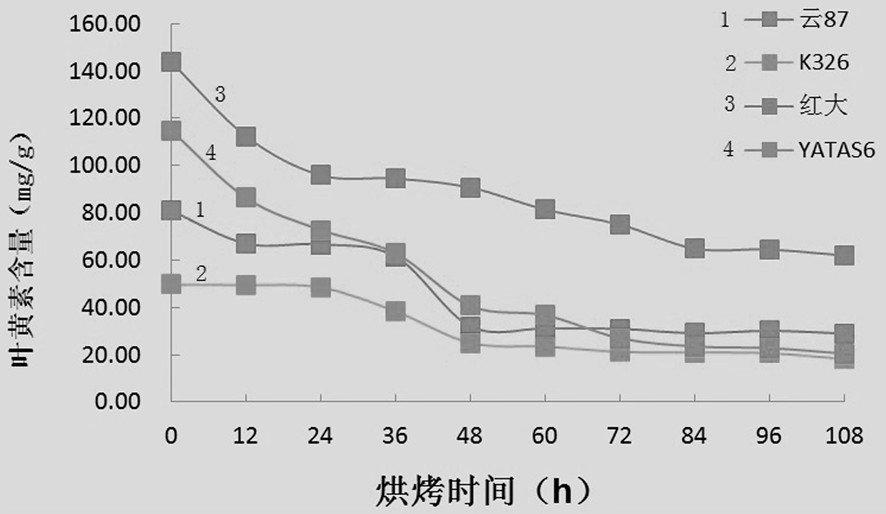

A curing process suitable for flue-cured tobacco variety nc-yatas6 tobacco leaves

ActiveCN109892683BHigh average priceImprove bake qualityTobacco preparationEconomic benefitsEngineering

The invention discloses a curing process suitable for flue-cured tobacco variety NC-YATAS6 tobacco leaves. The curing process harvests mature fresh tobacco leaves of the NC-YATAS6 variety for baking, and the curing includes the yellowing period, withering period, and color fixing The early stage, the late stage of color fixation and the dry gluten stage. The fresh tobacco leaves of the NC-YATAS6 variety are roasted by the process of the present invention. Compared with the conventional roasting process, the chroma is fuller, and the average price of the tobacco leaves is much higher than that of the conventional process technology. At the same time, the tobacco leaves obtained by adopting the curing process of the present invention not only have excellent curing quality and better smoking quality, but also improve the industrial usability of the cured tobacco leaves, significantly increase the economic benefits, and are easy to popularize and apply.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

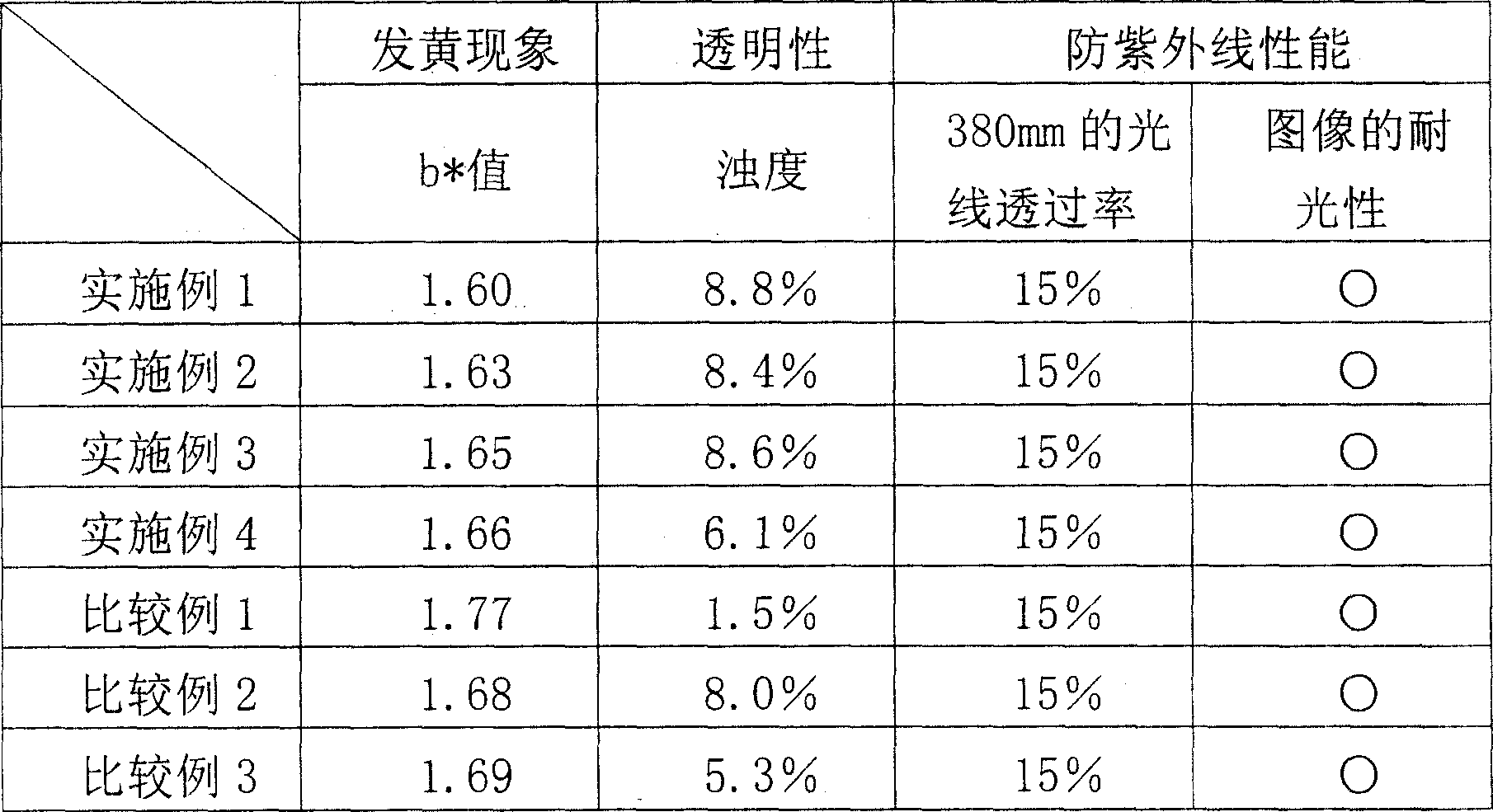

Surface protective sheet

InactiveCN100519177CImproves UV protectionImprove performanceSynthetic resin layered productsUv absorberUltraviolet protection

Disclosed is a surface protective sheet with less tinge of yellow which is excellent in ultraviolet protection. Specifically disclosed is a surface protective sheet having an ultraviolet protective layer on at least one side of a plastic film. The ultraviolet protective layer is composed of an ultraviolet absorbent, an ionizing radiation curable resin composition and spherical particles having an average particle size of 1-20 mum, and the spherical particles are contained in the ultraviolet protective layer in an amount of 0.4-3 weight%. Preferably, the ultraviolet protective layer further contains 0.01-1 weight% of organopolysiloxane.

Owner:KIMOTO CO LTD

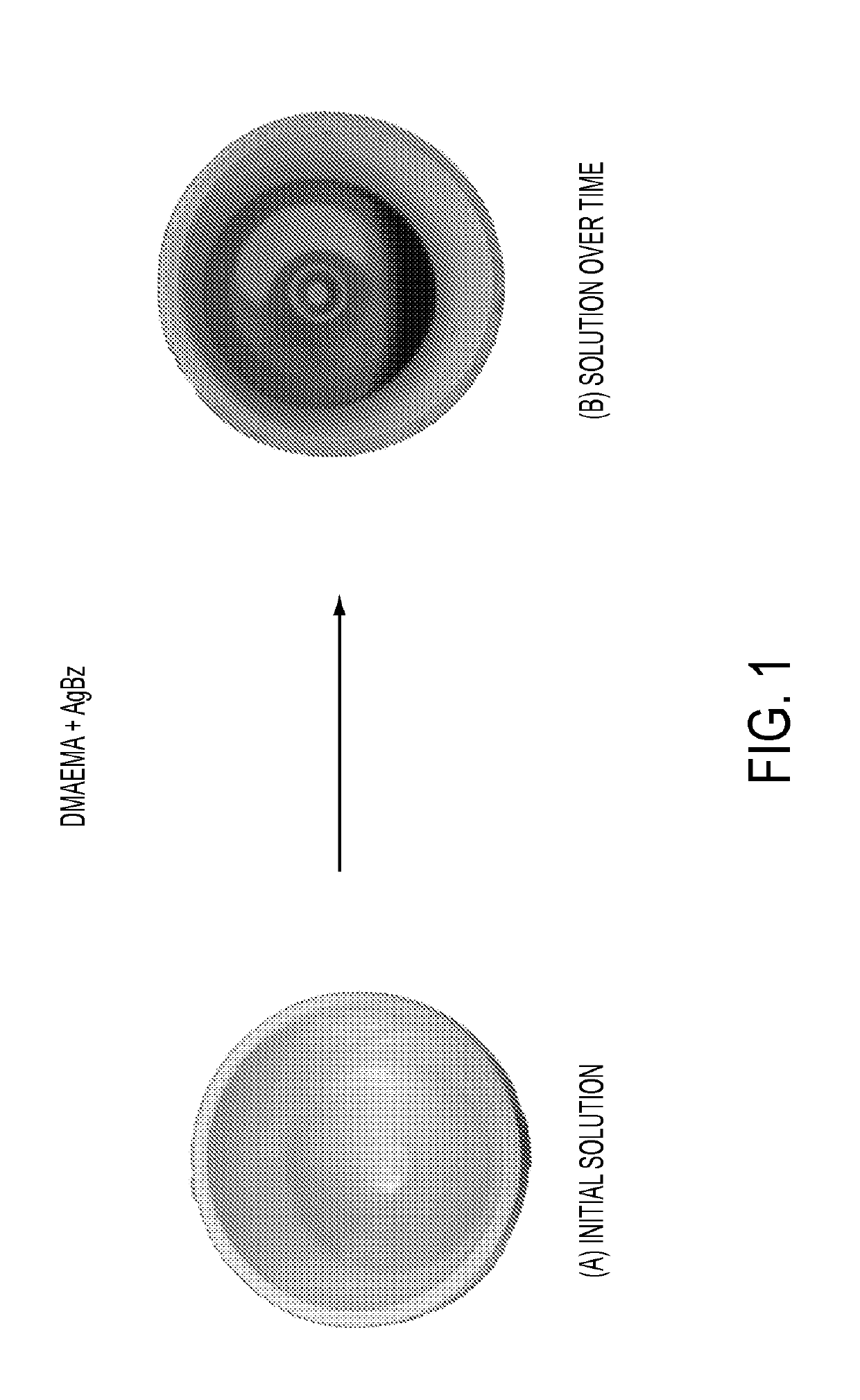

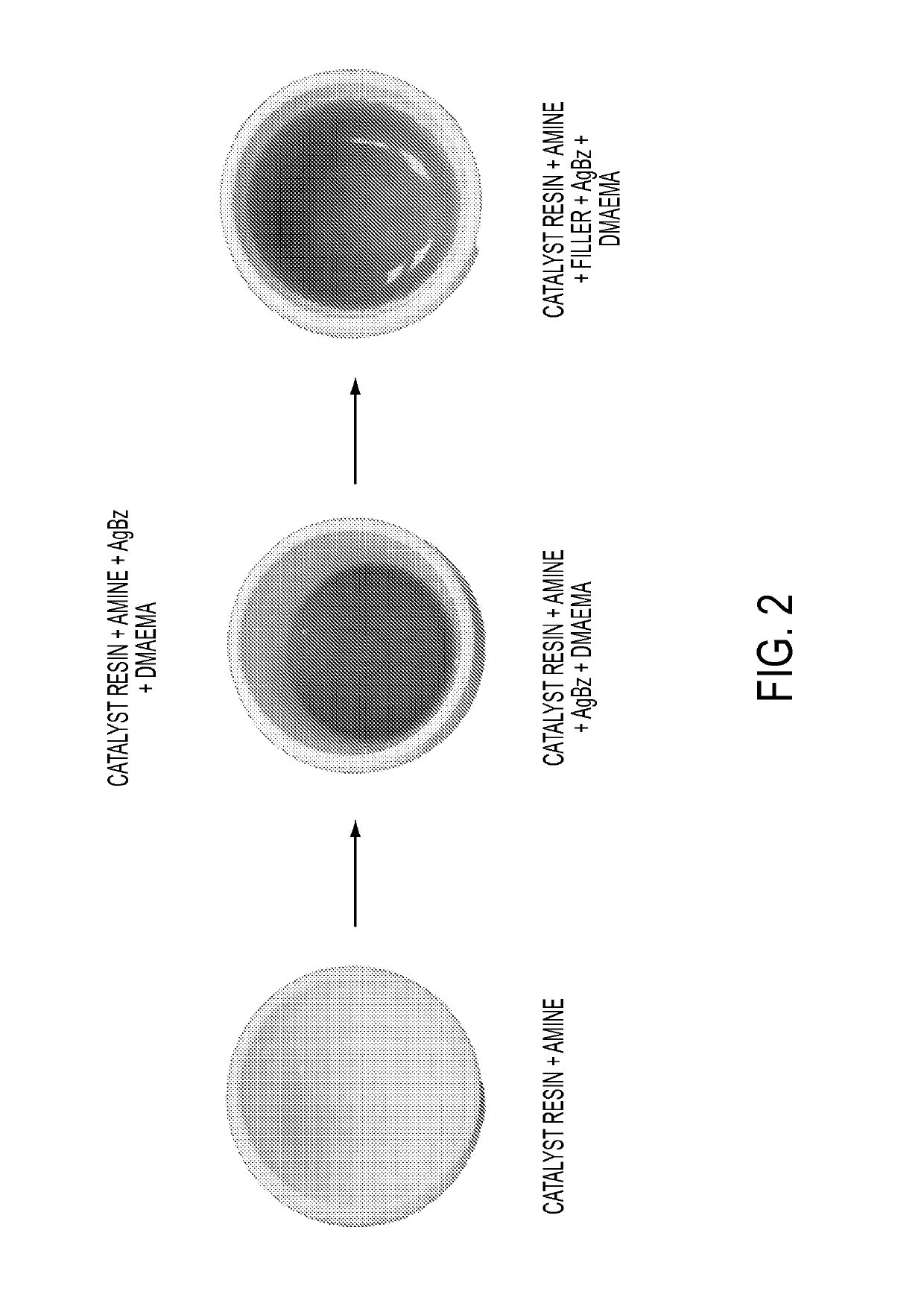

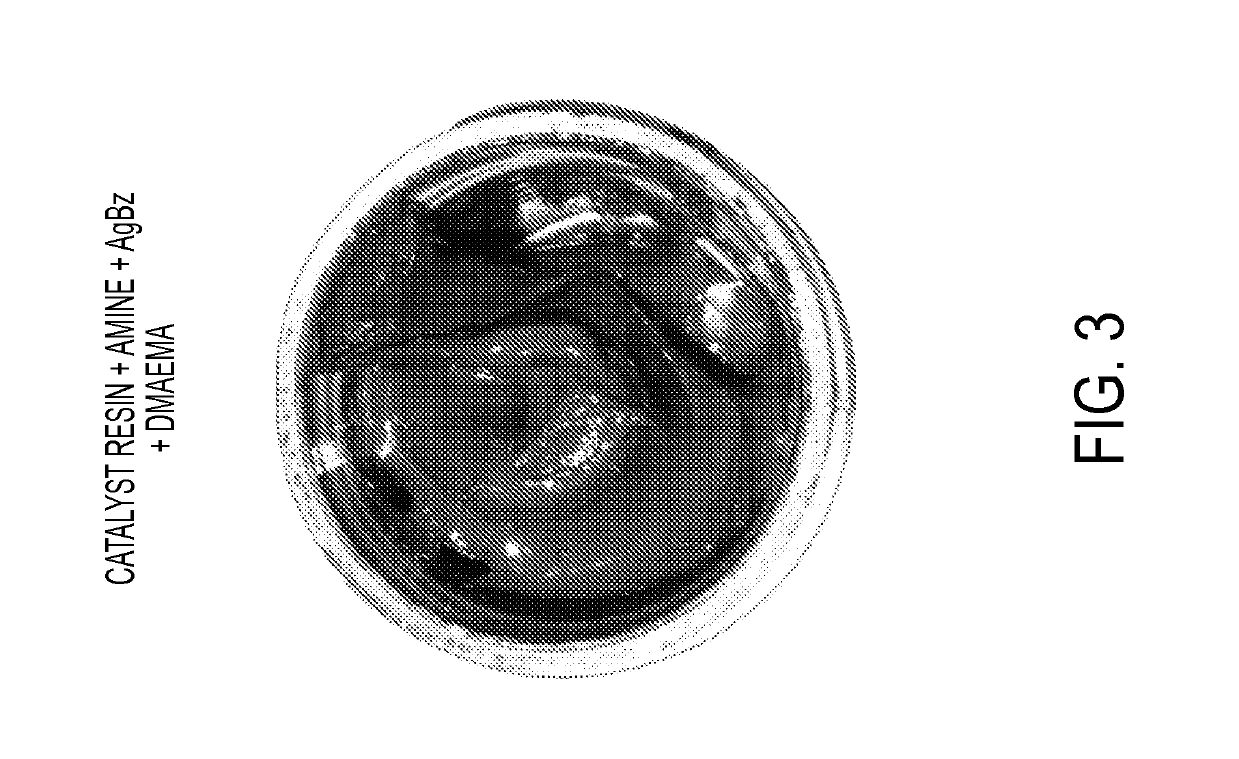

Improving shelf life and color profile of resin compositions with silver nanoparticles

Methods of forming antimicrobial resin compositions comprising silver nanoparticles are disclosed, wherein the resin compositions that are generated exhibit lower initial color, reduced color shift upon storage and reduced levels of spontaneous polymerization. Such methods generally comprise: combining a silver-containing material with a self-cure and dual-cure base resin in situ wherein the base resin does not contain a catalytic amine; and adding a catalytic resin to the mixture of the resin and silver-containing material in order to form the final cured resin. Antimicrobial polymeric materials formed by said methods are also disclosed.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

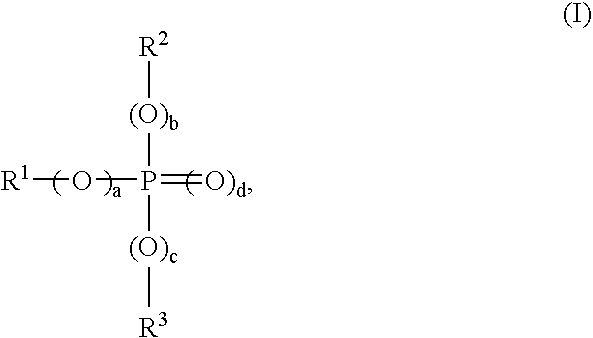

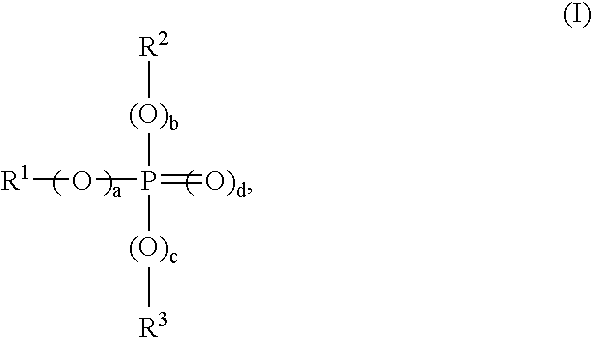

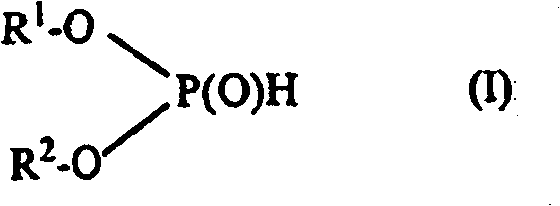

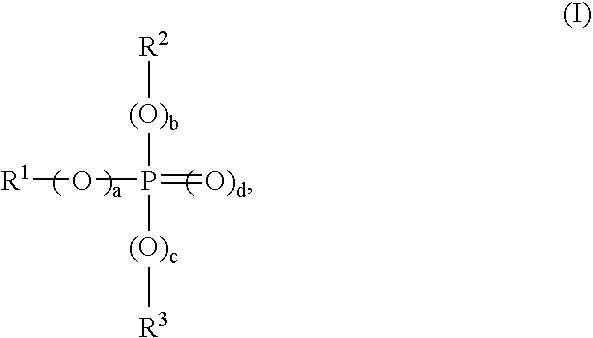

Use of phosphonic acid diesters and diphosphonic acid diesters and thermally curable mixtures containing phosphonic acid diesters and diphosphonic acid diesters

ActiveCN101268158BHigh hardnessGood chemical resistancePhysical/chemical process catalystsPolyurea/polyurethane coatingsTrans esterificationPtru catalyst

The invention relates to the use of phosphonic acid diesters and diphosphonic acid diesters (A) as reactants and / or catalysts for compounds (B) that can be reacted by transesterification, transamidation, self-condensation of N-hydroxyalkylamine groups and / or N-alkoxyalkylamine groups, transacetalization of N-alkoxyalkylamine groups and / or acetalization of N-hydroxyalkylamine groups. The inventionalso relates to thermally curable mixtures containing phosphonic acid diesters and diphosphonic acid diesters (A) and to methods for producing the same.

Owner:BASF COATINGS GMBH

Fatliquoring agents for the flame-retardant treatment of leather

InactiveUS7749409B2Pleasant odorLess yellowingPre-tanning chemical treatmentFibre treatmentOrganic phosphorusOrganic chemistry

The present invention relates to fatliquoring agents for leathers, skins or hides, which contain neutral halogen-free organic phosphorus compounds, and the use of such fatliquoring agents for the flame-retardant treatment of leather and a process for fatliquoring in the production of flame-retardant leather, skin or hides.

Owner:LANXESS DEUTDCHLAND GMBH +1

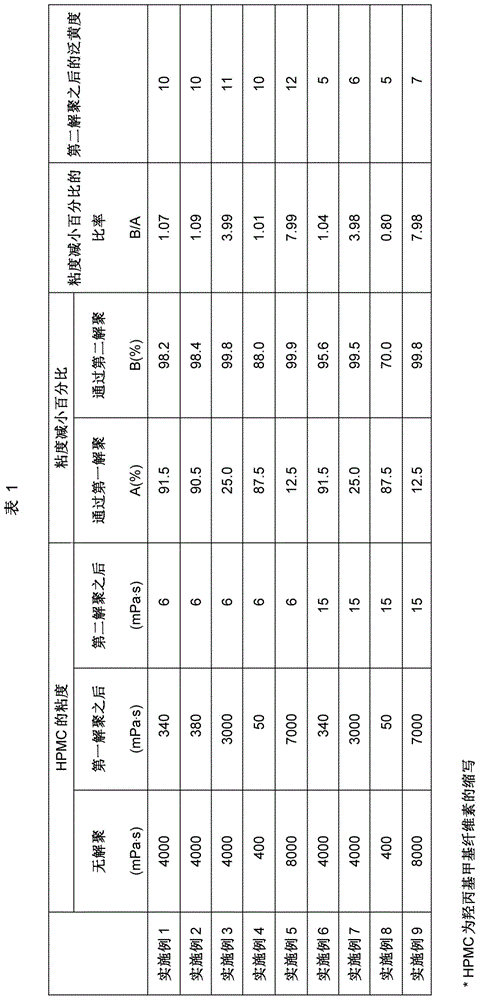

Process for preparing cellulose ether with low degree of polymerization and cellulose ether prepared therefrom

ActiveCN103910803BReduce the degree of polymerizationLess yellowingPharmaceutical non-active ingredientsCelluloseDepolymerization

Provided are a method for preparing a cellulose ether having a low degree of polymerization and undergoing less yellowing and a cellulose ether prepared thereby. More specifically, provided is a method for preparing a cellulose ether having a low degree of polymerization, the method comprising a step of bringing pulp and an alkali metal hydroxide solution into contact with each other or mixing them to obtain a corresponding alkali cellulose, a first depolymerization step of reacting the alkali cellulose with oxygen to adjust a viscosity reduction percentage of the alkali cellulose to from 10 to 95%, a step of reacting the depolymerized alkali cellulose with an etherifying agent, a step of washing and drying the reaction product to obtain a cellulose ether, and a second depolymerization step of bringing the cellulose ether into contact with hydrochloric acid to adjust a viscosity reduction percentage of the cellulose ether to from 40 to 99.9%.

Owner:SHIN ETSU CHEM IND CO LTD

Dual-cure dental resins and adhesives with increased cure and color-stability and low color

InactiveUS20140141390A1Low color requirementHigh degree of curingImpression capsTeeth fillingAdhesiveDual curing

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Process for making a fluoropolymer dispersion

The invention relates to a process to produce a stable fluoropolymer latex using non-fluorinated surfactant with greater thermal stability. The polymerization is run at pressures greater than typically used. The resulting polymer exhibit improved melt color stability as compared to those produced under similar conditions at lower pressures.

Owner:ARKEMA INC

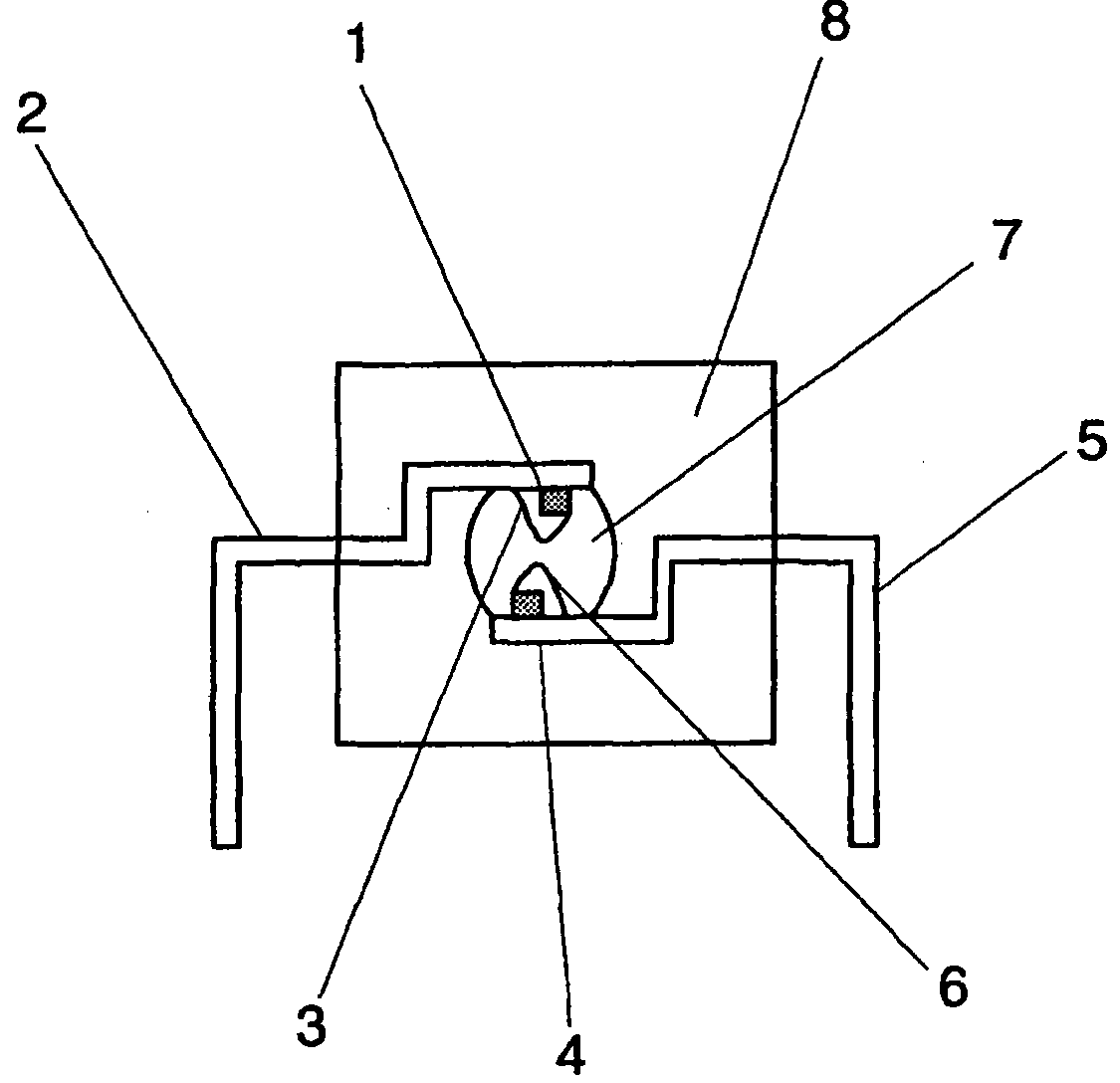

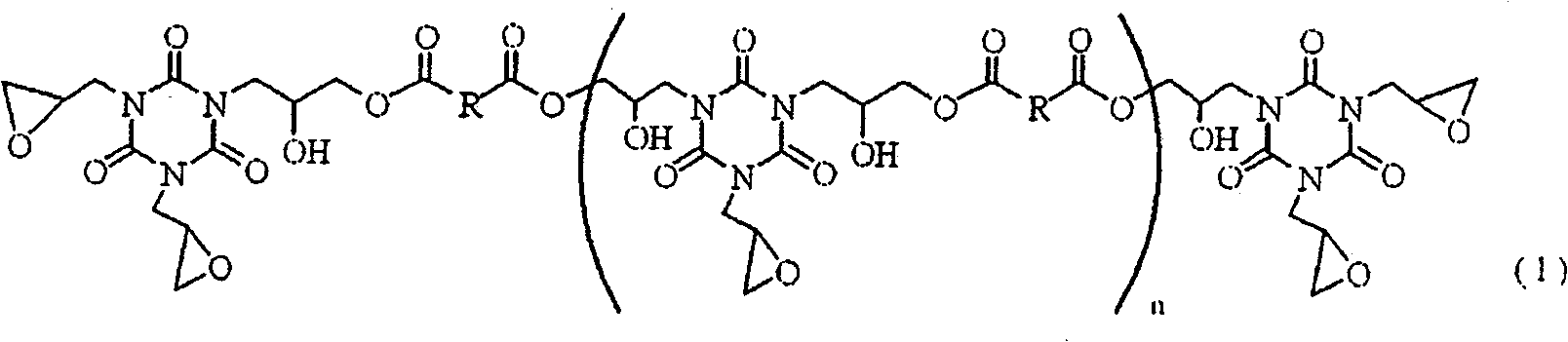

Thermosetting epoxy resin composition and semiconductor device

ActiveCN101283016BImprove curing effectHigh strengthSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

A thermosetting epoxy resin composition characterized by containing as a resin ingredient a product of pulverization of a solid matter obtained by reacting a triazine derivative / epoxy resin with an acid anhydride in such a proportion that the amount of the epoxy groups is 0.6-2.0 equivalents to the acid anhydride groups.

Owner:SHIN ETSU CHEM CO LTD

Photopolymerizable inkjet ink, ink cartridge, and inkjet recording device

To provide a photopolymerizable inkjet ink including: diethylene glycol dimethacrylate; caprolactone-modified dipentaerythritol hexaacrylate; and a photopolymerization initiator represented by the following general formula (1):where X1 is represented by the following general formula (1-1), and X2 is represented by the following general formula (1-2):where R1 to R4 are each independently a C1-C6 alkyl group, and R1 and R2 may be linked to form a ring, and R3 and R4 may be linked to form a ring; Z1 and Z2 is —NR5R6 or OR7; R5 and R6 are each independently a C1-C6 alkyl group, and R5 and R6 may be linked to form a ring; and R7 is a hydrogen atom, a methyl group, or a trimethylsilyl group.

Owner:RICOH KK

Styrene-acrylonitrile copolymer foam with minimal yellowing

ActiveUS20130053466A1Reduce concentrationLess yellowingPeptide preparation methodsAcrylonitrileStyrene

Prepare polymeric foam articles having low yellowing using a styrene-acrylonitrile copolymer that contains less than 145 weight-parts acrylonitrile dimer and less than 8,500 weight-parts acrylonitrile trimer per million weight parts acrylonitrile copolymer.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com