Telescopic oil level sensor device

An oil level sensor and an integrated technology, applied in the field of oil level sensor devices and retractable oil level sensor devices, can solve the problem that the oil at the bottom of the fuel tank cannot be used, cannot truly reflect the oil volume of the fuel tank, and the oil level sensor has a single function and other issues to achieve the effect of light weight, light weight and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

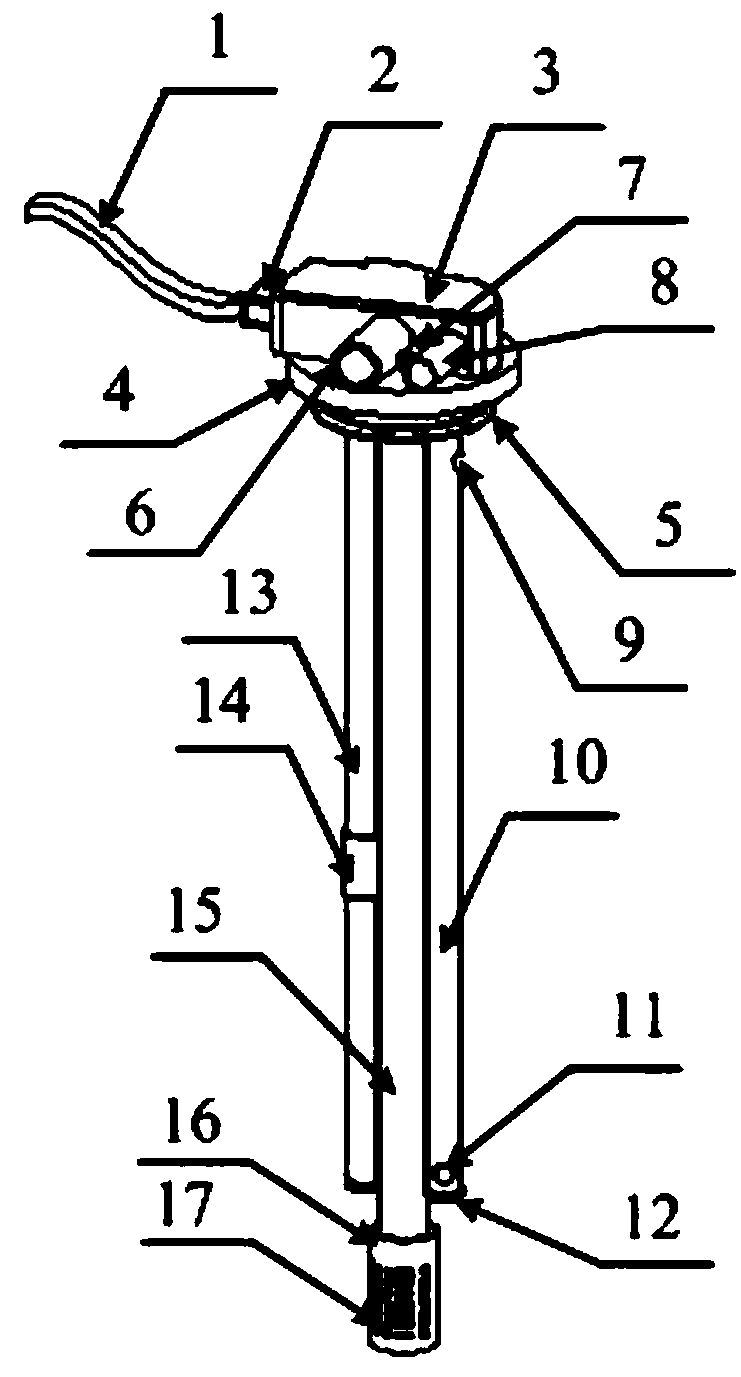

[0036] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0037] as attached figure 1 And attached figure 2 As shown, a retractable oil level sensor device of the present invention includes the following parts:

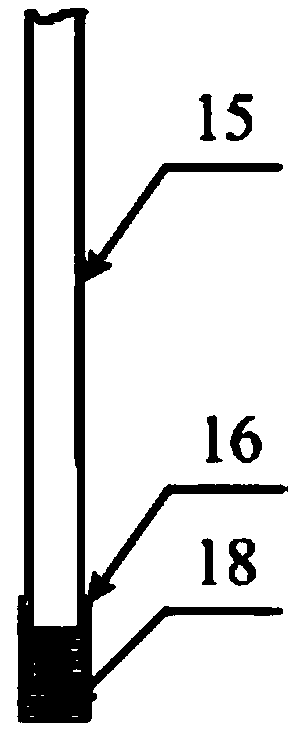

[0038]Signal cable 1, cable interface 2, electrical box 3, mounting flange 4, sealing ring 5, oil suction pipe interface 6, exhaust pipe interface 7, oil return pipe interface 8, exhaust hole 9, oil return pipe 10, oil return port 11 , blocking cover 12, induction tube 13, oil float 14, oil suction pipe 15, filter screen cover 16, filter screen 17, spring 18; the relationship between them is: signal cable 1 is connected to electrical box 3 through cable interface 2, electrical appliance The box 3 is located on the upper part of the installation flange 4, and the installation flange 4 is provided with a sealing ring 5; the oil suction pipe interface 6, the exhaust pipe interface 7 and the oil ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com