An Optimal Segmented Automatic Shearing Control System for Thick Plate Cutting Shear

A control system, the best technology, applied in general control system, control/adjustment system, program control, etc., can solve the large deviation in the calculation of the length of the mother plate, which is not conducive to the yield of thick plates, and affects the cutting head and shearing segments. Accuracy and other issues to achieve the effect of improving on-site logistics and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

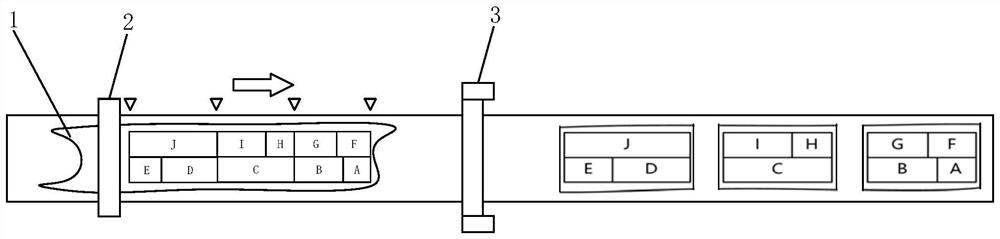

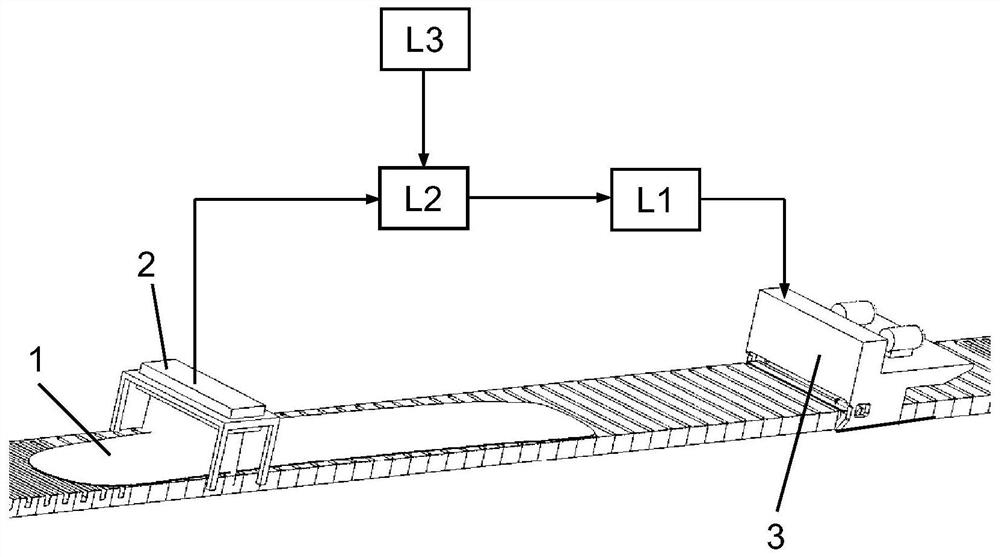

[0032] see figure 1 , figure 2 , Figure 8 As shown, the optimal segmented automatic cutting control system of thick plate shears according to the present invention mainly includes a plane shape detection device 2, a production control computer L3, a process automation computer L2, and a basic automation computer L1.

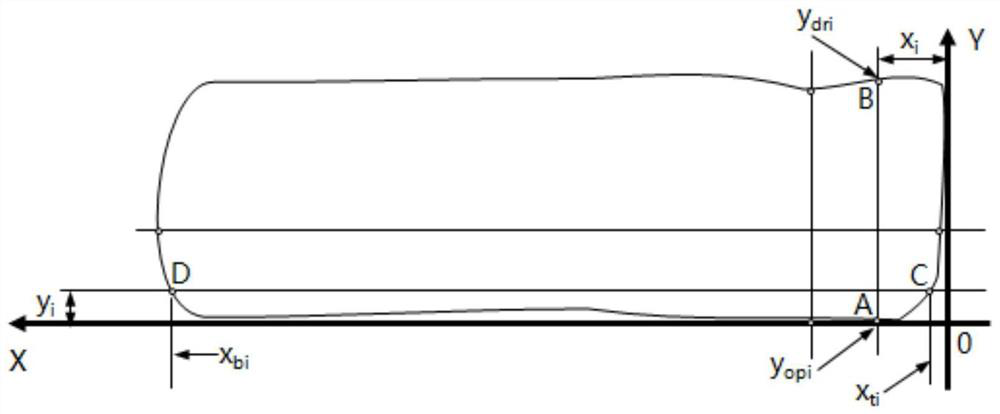

[0033] Wherein, the planar shape detection device 2 (Plate Shape Gauge, referred to as PSG, manufacturer such as German LAP radium spectrum, etc.) is arranged before the shearing machine 3, and the planar two-dimensional shape scanning is carried out to the steel plate 1 to be cut by the shear head, so as to Obtain the edge contour position coordinates of the rolled slab 1, and send it to the process automation computer;

[0034] The production control computer sends the original planning data of rolling large slab design to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com