Tunable liquid crystal laser based on SU8 grating and manufacturing method thereof

A manufacturing method and laser technology, applied in the direction of lasers, laser parts, phonon exciters, etc., can solve the problems of liquid crystal molecular helical arrangement being easily destroyed, the intensity of outgoing laser light is weak, and the output effect of wavelength tuning is unstable, etc. The effect of integration, stable wavelength tuning output, and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the drawings and embodiments.

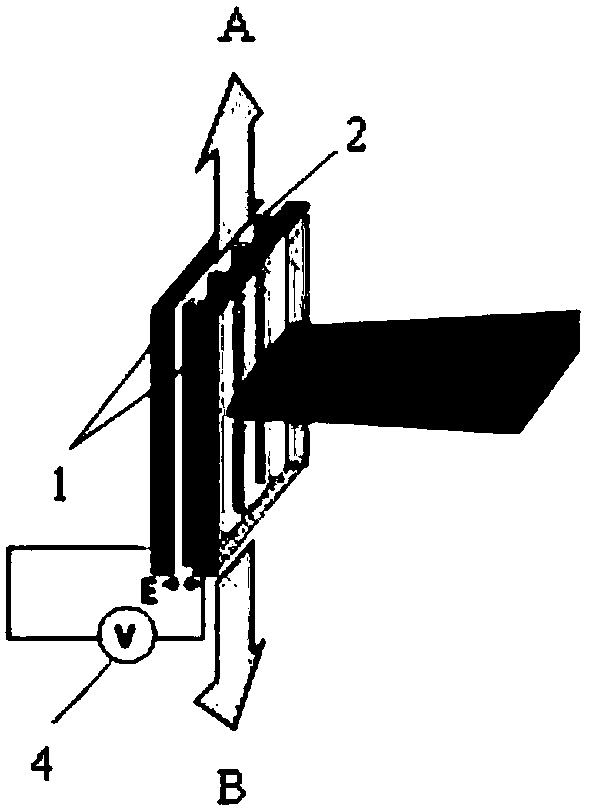

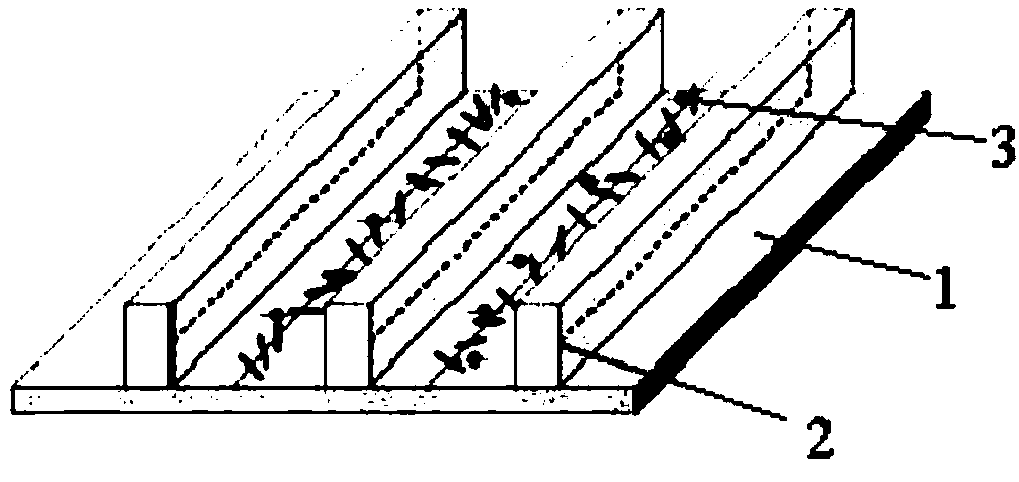

[0019] Such as figure 1 with figure 2 As shown, a tunable liquid crystal laser based on an SU8 grating includes an ITO glass substrate 1, an SU8 grating 2 is uniformly arranged between two ITO glass substrates 1, and a mixture of chiral liquid crystal 3 and dyes is filled in the channels of the SU8 grating 2. An AC voltage is applied between the electrodes of the two ITO glass substrates 1 through an AC power source 4.

[0020] A manufacturing method of a tunable liquid crystal laser based on SU8 grating, the specific operation is as follows, including the following steps:

[0021] Step 1. The cut ITO glass substrate 1 is ultrasonically cleaned with ethanol, isopropanol, and deionized water for 10 minutes, and baked in an oven at 100°C for 30 minutes to remove moisture. The ITO glass substrate 1 is 10mm×10mm;

[0022] Step 2: Coat the SU8 photoresist evenly on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com