Improved highland barley all-powder steamed bread and preparation method thereof

A technology for highland barley and steamed buns, which is applied in the field of improving highland barley whole flour steamed buns and its preparation, can solve the problems that the nutritional and health care functions of highland barley are not further improved, the digestion performance and nutritional function modification of highland barley flour, etc. Sensory quality, effect of improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The moisture content of the highland barley flour was adjusted to 20%, and placed in a moist heat treatment system for moist heat treatment, wherein the reaction temperature was 100° C., and the reaction time was 3 hours. After the reaction, the highland barley powder was taken out, dried at 40° C. for 12 hours, crushed, and passed through an 80-mesh sieve to obtain whole highland barley powder treated with heat and humidity.

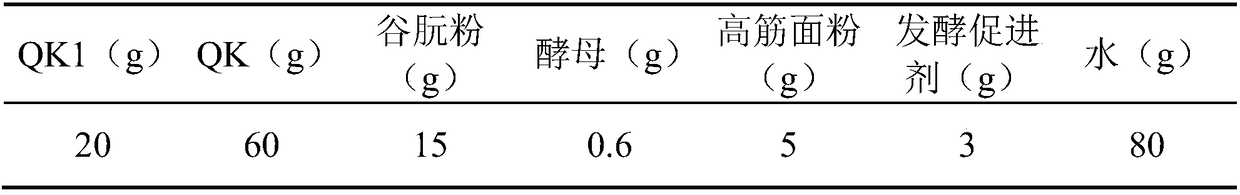

[0031] After the heat-treated highland barley whole powder (QK1) and former highland barley whole powder (QK) are crossed through a 100 mesh sieve (according to the dosage shown in Table 1), mix with gluten, yeast, high-gluten flour, fermentation accelerator (10 parts of molasses, 0.005 parts of α-amylase) was mixed in a dough mixer for 2 minutes, added water (according to the amount shown in Table 1) and stirred for 12 minutes to form a dough. Then put the dough through the tablet machine for 5 times, knead it evenly and put it in a proofer at 3...

Embodiment 2

[0035] The moisture content of the highland barley flour was adjusted to 15%, and placed in a moist heat treatment system for moist heat treatment, wherein the reaction temperature was 100° C., and the reaction time was 2 hours. After the reaction is finished, the highland barley powder is taken out, dried at 40°C for 24 hours, crushed, and passed through an 80-mesh sieve to obtain the highland barley powder treated with heat and humidity.

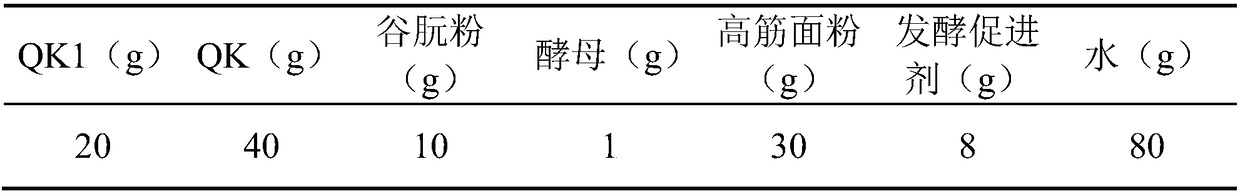

[0036] With the highland barley whole powder (QK1) after the heat treatment, the former highland barley whole powder (QK) (QK) crossed 100 mesh sieves with gluten, yeast, high-gluten flour, fermentation accelerator (10 parts of molasses, 0.005 parts of α-amylase) was mixed in a dough mixer for 5 minutes, added water (according to the amount shown in Table 2) and stirred for 20 minutes to form a dough. Then put the dough through the tablet machine for 10 times, knead it evenly and put it in a proofer at 40°C for 3 hours. After the dough is d...

Embodiment 3

[0040] The moisture content of the highland barley flour was adjusted to 30%, and placed in a moist heat treatment system for moist heat treatment, wherein the reaction temperature was 130° C., and the reaction time was 3 hours. After the reaction, the highland barley powder is taken out, dried at 40° C. for 24 hours, crushed, and passed through an 80-mesh sieve to obtain whole highland barley powder treated with heat and humidity.

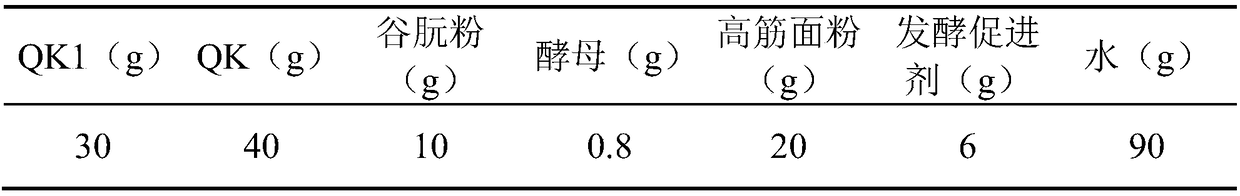

[0041] With the highland barley whole powder (QK1) after the heat treatment, the former highland barley whole powder (QK) (QK) with gluten, yeast, high-gluten flour, fermentation accelerator (15 parts of molasses, 0.015 parts of α-amylase) was mixed in a dough mixer for 5 minutes, added water (according to the amount shown in Table 3) and stirred for 20 minutes to form a dough. Then put the dough through the tablet machine for 10 times, knead it evenly and put it in a proofer at 38°C for 3 hours. After the dough is divided into shapes, it is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com