Externally-applicable composition for treatment of burns and scalds and preparation method of externally-applicable composition for treatment of burns and scalds

A composition for external use and the technology of the composition are applied in the direction of medical preparations containing active ingredients, drug combinations, active ingredients of hydroxyl compounds, etc., which can solve problems such as inability to relieve pain quickly, inconvenient use, and long course of treatment, and achieve process optimization, The effect of complete extraction and improved curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Example 1 Spray

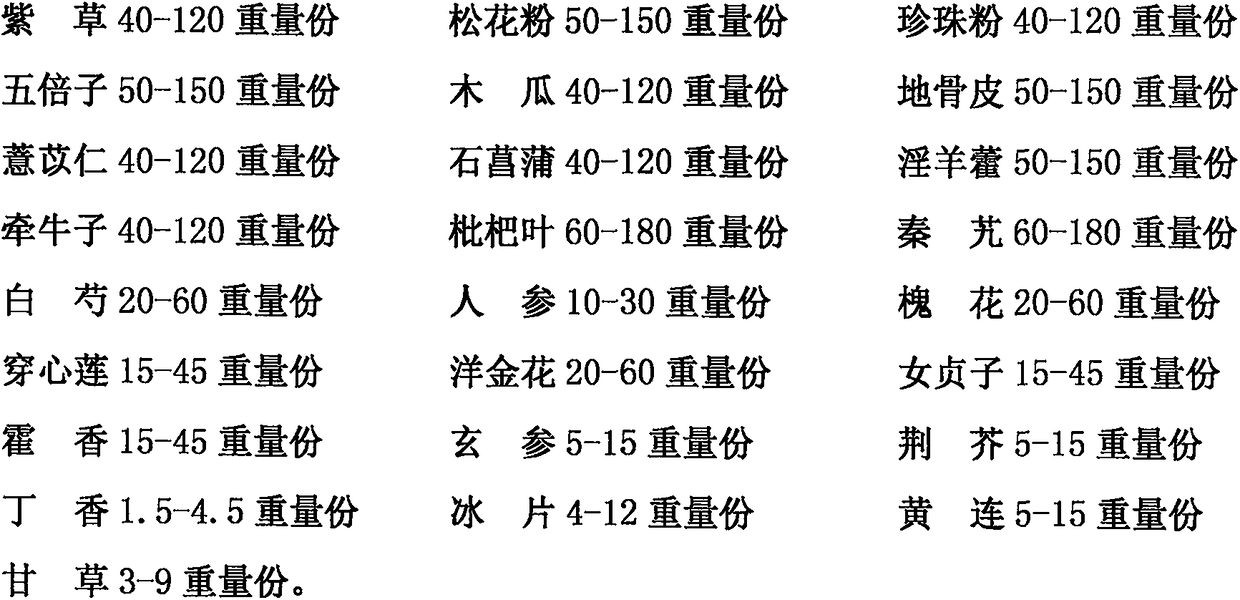

[0098]

[0099] Take 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory, and Gentiana to obtain superfine powders of 40 meshes, and put the superfine powders, all pine pollen and pearl powder in CO 2 Soak in the extraction kettle for 2 hours, control the pressure in the extraction kettle to 25MPa, separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2The flow rate is maintained at 30Kg / h. After separation, the extract A is obtained. The remaining 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory and Gentiana plus 4 times the amount of water are soaked for 60 minutes , and then decocting, decocting for the first time for 1 hour, and filtering to obtain the filtrate; decocting the dregs with 2 times the amount of water for 0.4 hours, filtering to obtain the filtrate, combining the two filtrate...

Embodiment 2

[0100] Example 2 Spray

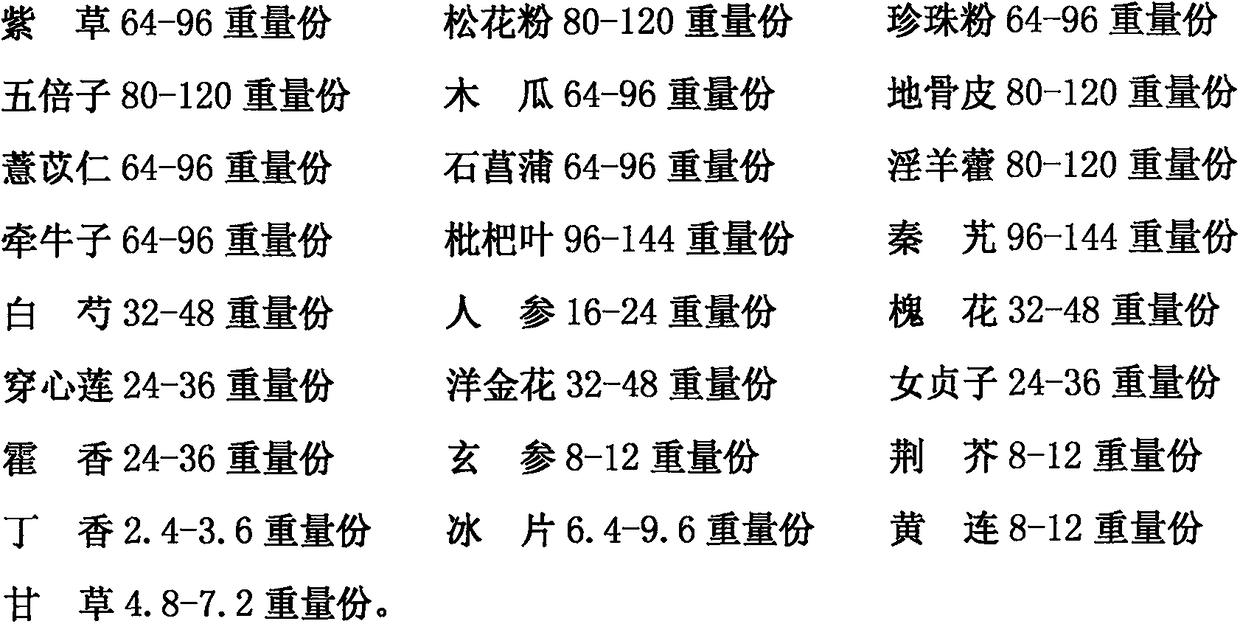

[0101]

[0102] Take 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory, and Gentiana to obtain superfine powders of 40 meshes, and put the superfine powders, all pine pollen and pearl powder in CO 2 Soak in the extraction kettle for 2 hours, control the pressure in the extraction kettle to 25MPa, separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2 The flow rate is maintained at 30Kg / h. After separation, the extract A is obtained. The remaining 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory and Gentiana plus 4 times the amount of water are soaked for 60 minutes , and then decocting, decocting for the first time for 1 hour, and filtering to obtain the filtrate; decocting the dregs with 2 times the amount of water for 0.4 hours, filtering to obtain the filtrate, combining the two filtra...

Embodiment 3

[0103] Example 3 Spray

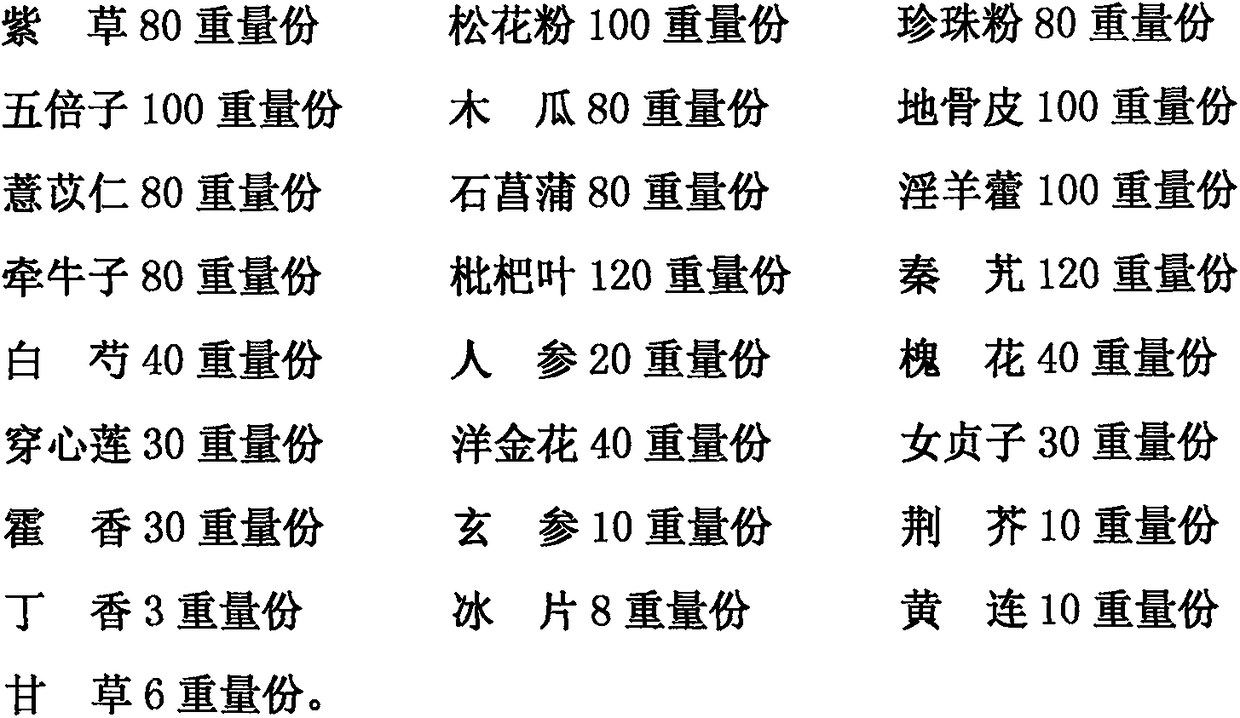

[0104]

[0105] Take 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory, and Gentiana to obtain superfine powders of 40 meshes, and put the superfine powders, all pine pollen and pearl powder in CO 2 Soak in the extraction kettle for 2 hours, control the pressure in the extraction kettle to 25MPa, separate the soaked ultrafine powder in the separation kettle, control the separation pressure value in the separation kettle to 6MPa, heat to 40°C, keep for 5 hours, CO 2 The flow rate is maintained at 30Kg / h. After separation, the extract A is obtained. The remaining 1 / 2 of comfrey, Galla gall, Digupi, Coix seed, Epimedium, Morning Glory and Gentiana plus 4 times the amount of water are soaked for 60 minutes , and then decocting, decocting for the first time for 1 hour, and filtering to obtain the filtrate; decocting the dregs with 2 times the amount of water for 0.4 hours, filtering to obtain the filtrate, combining the two filtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com