Load type lithium adsorbent and preparation method thereof

A lithium adsorption and loading technology, applied in the field of loaded lithium adsorbent and its preparation, can solve the problems of decreased adsorption performance, low mechanical strength of the adsorbent, poor water permeability of the adsorbent, etc., and achieves the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

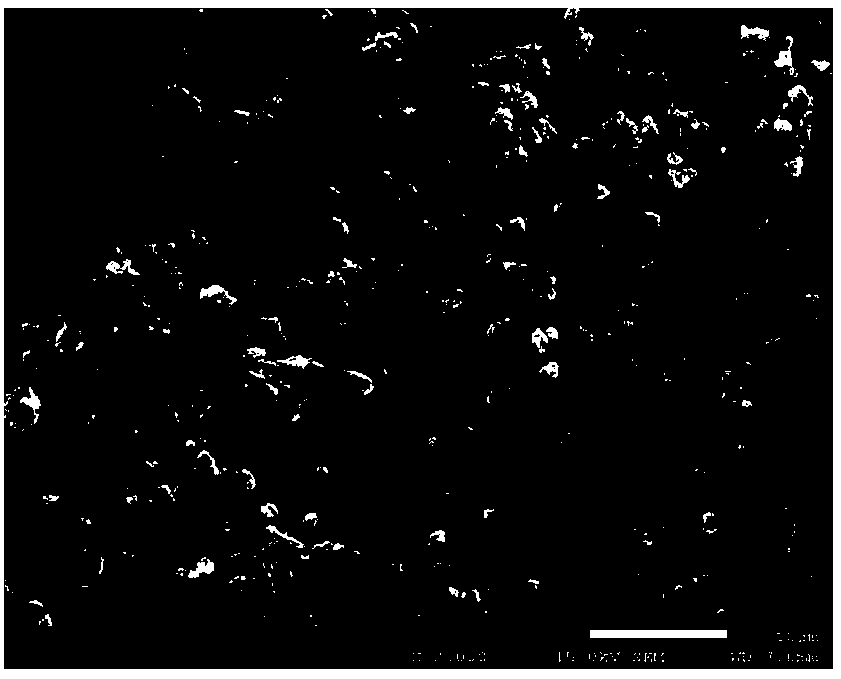

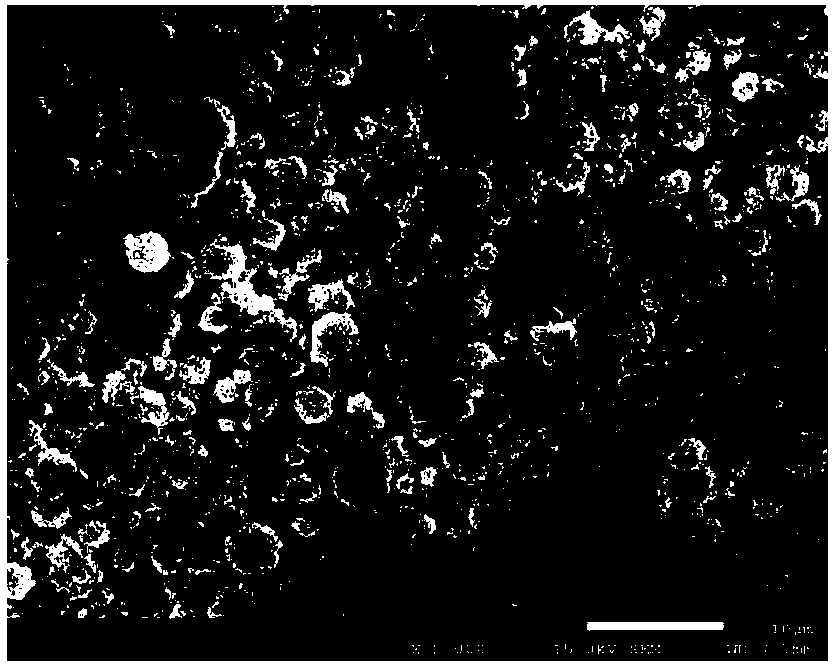

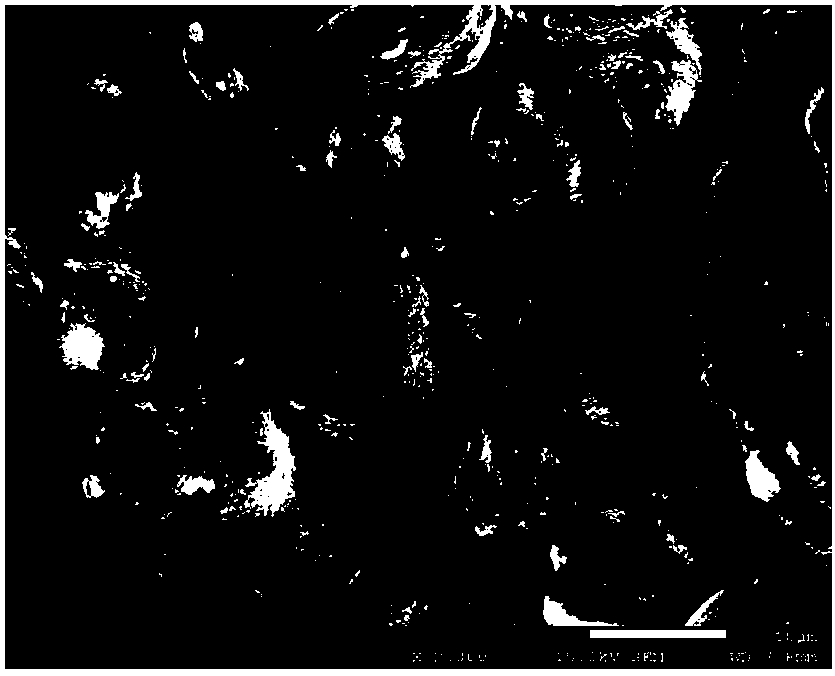

Image

Examples

preparation example Construction

[0024] According to the present invention, the lithium adsorbent powder can be various conventional lithium adsorbent powder materials of the present invention, such as aluminum salt lithium adsorbent, lithium titanium oxide lithium adsorbent and lithium manganese oxide lithium adsorbent. one or more of the agents. The lithium adsorbent powder can be commercially available, or can be prepared by conventional methods in the art. Wherein, taking the preparation of the aluminum salt lithium adsorbent as an example, the preparation method of the aluminum salt lithium adsorbent comprises: aluminum hydroxide and lithium hydroxide (the amount of which makes the molar ratio of Al and Li be 1.8-2.2:1) Mix (for example, use a high-speed mixer for 20-40min), then heat in an air atmosphere (for example, heat at 180-220°C for 2-4h), and then add water (the amount of water is such that the weight ratio of water to powder is 2 -5:1) for mixing, the resulting mixture is subjected to aging tr...

preparation example 1

[0045] This preparation example is used to illustrate the preparation of lithium adsorbent powder.

[0046] (1) Mix aluminum hydroxide and lithium hydroxide monohydrate (in such an amount that the molar ratio of Al and Li is 2:1) in a high-speed mixer for 30 minutes; and heat the resulting mixture in air at 200°C for 3 hours;

[0047] (2) Add the powder obtained in step (1) into an appropriate amount of deionized water (the weight ratio of water to powder is 3:1), stir evenly, age at 70°C for 3 hours, add hydrochloric acid to adjust the upper layer after cooling Water phase to pH 5.3;

[0048] (3) Separate and dry the powder.

Embodiment 1

[0050] This example is used to illustrate the supported lithium adsorbent of the present invention and its preparation method.

[0051] (1) Bisphenol A type epoxy resin E-51 (purchased from Guangzhou Aichuan Chemical Co., Ltd., the consumption in dry weight is 10 parts by weight), epoxy curing agent (purchased from Jiangmen City Good Chemical Co., Ltd. GG-6689 brand, the consumption in terms of dry weight is 5 parts by weight), acetone (consumption is 10 parts by weight) and the aluminum salt lithium adsorbent powder (consumption is 75 parts by weight) of Preparation Example 1 gained are stirred and mixed to obtain Liquid;

[0052] (2) Add the hollow polyhedral ball filler into the feed liquid (the volume ratio of the total volume of the hollow polyhedral ball filler to the feed liquid is 1:1.5), and stir evenly;

[0053] (3) Put the hollow polyhedral spherical filler body loaded with the material liquid into an oven and heat and solidify at 100° C. for 1 hour to obtain the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com