A device and method for preparing composite roll/compound steel ingot by electroslag casting method

A technology of electroslag casting and composite roll, applied in the field of metallurgy, can solve the problem of uneven material properties in the axial direction, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

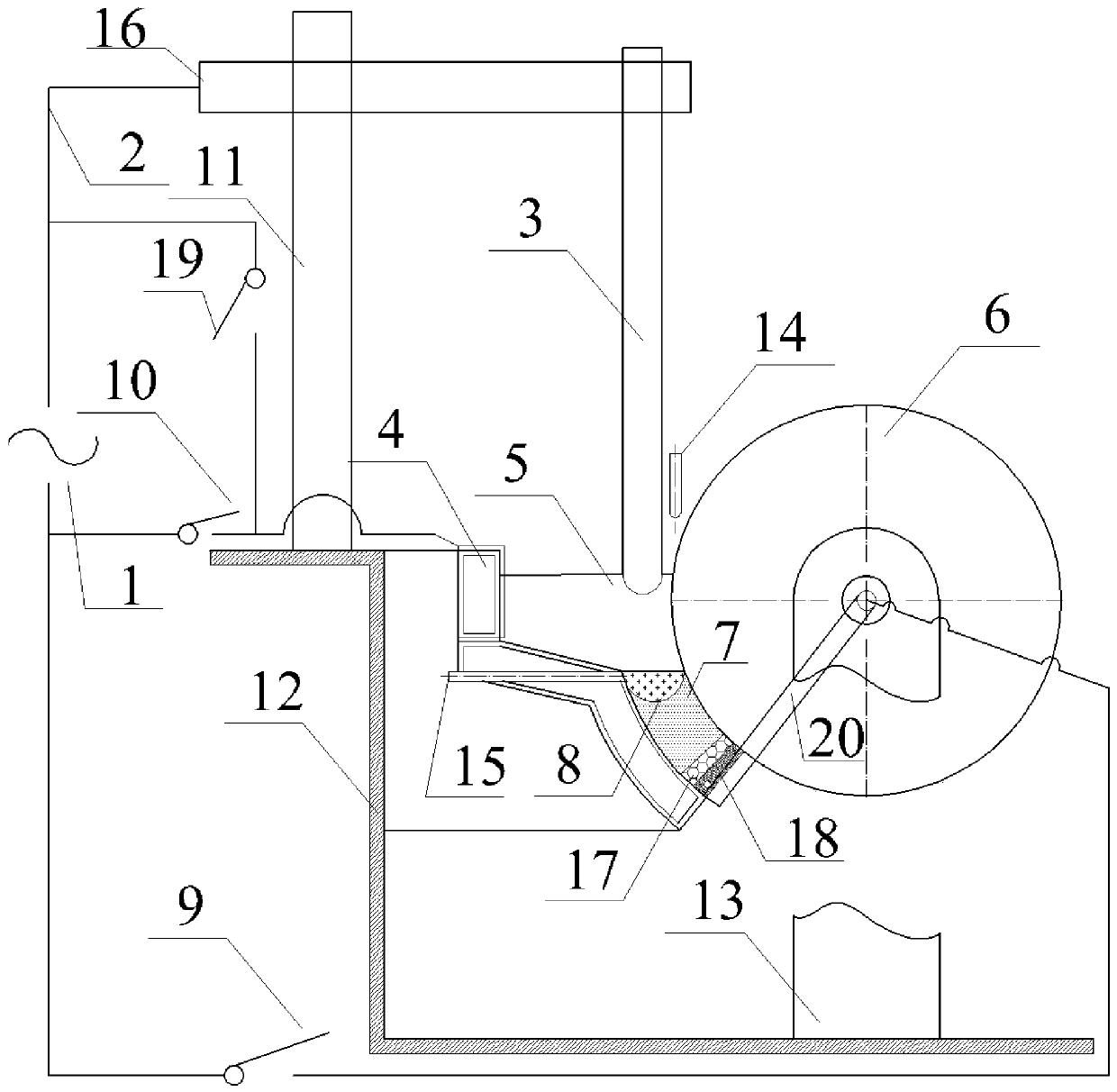

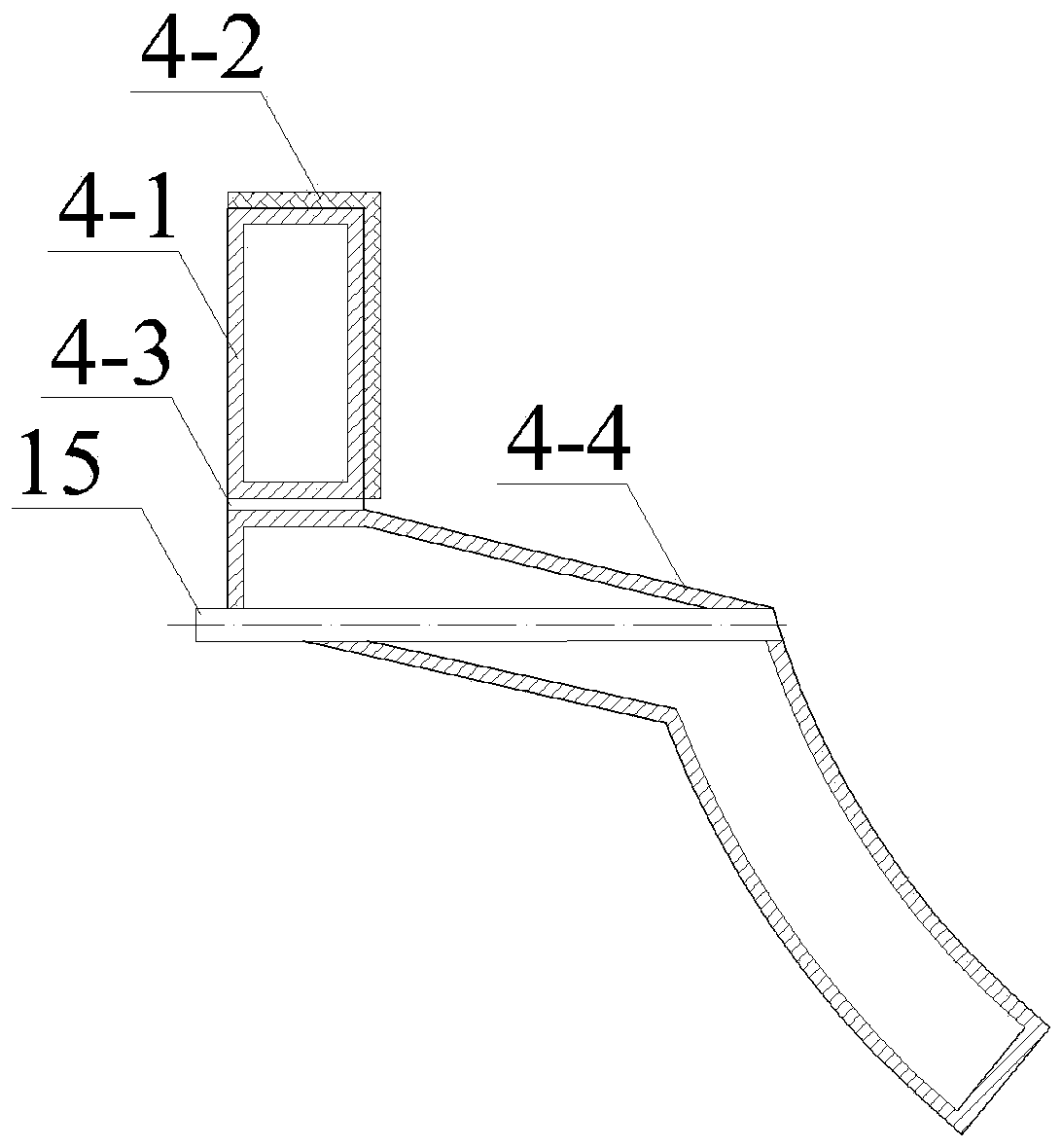

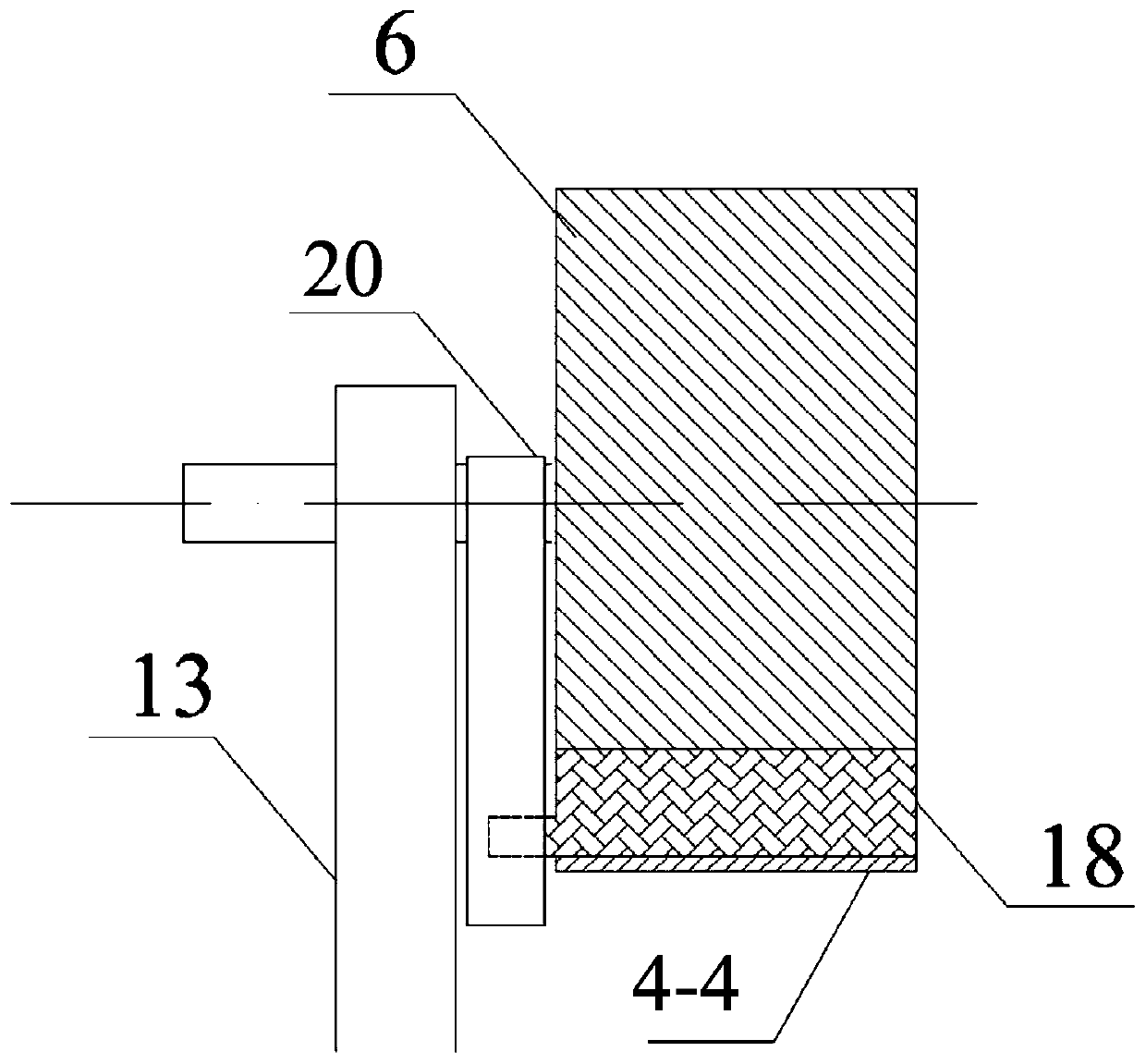

[0048] The structure of the device for preparing composite roll / compound steel ingot by electroslag casting method is as follows: figure 1 As shown, including L-type crystallizer (4), electrode system and power supply system; L-type crystallizer (4) structure is as follows figure 2 As shown, it is mainly composed of an upper crystallizer (4-1), a conductive graphite plate (4-2), a high temperature resistant insulating plate (4-3) and a lower crystallizer (4-4); the lower crystallizer (4-4 ) is provided with a liquid level detector (15); the electrode system, the L-shaped crystallizer (4) and the bearing seat (13) are fixed on the crystallizer support (12), and the electrode support arm (11) of the electrode system is assembled There is a cross arm (16), and the cross arm (16) is used to suspend the dummy electrode and the self-consumed electrode (3), and the bearing seat (13) is used to place the bearing of the mandrel shaft jacket of the mandrel (6); the power supply system ...

Embodiment 2

[0075] Device structure is the same as embodiment 1;

[0076] Method is with embodiment 1, and difference is:

[0077] When preheating the mandrel, connect the circuit I switch and the circuit III switch, so that the power supply, short network, conductive graphite plate, slag pool and mandrel form the second mandrel preheating power supply circuit;

[0078] There are no pores, inclusions, cracks and other defects at the interface of the composite roll, and the depth of the radial and axial fusion layers is uniform and uniform, and the quality of the composite interface is good.

Embodiment 3

[0080] Device structure is the same as embodiment 1;

[0081] Method is with embodiment 1, and difference is:

[0082] (1) The width of the consumable electrode is 40mm, the length is 1000mm, the diameter of the mandrel is Φ400mm, and the length is 1000mm;

[0083] (2) The inner diameter of the upper crystallizer is 600mm, the inner diameter of the lower mold is Φ520mm, the diameter of the composite roll expected to be prepared is Φ520mm, and the thickness of the composite layer is 60mm;

[0084] There are no pores, inclusions, cracks and other defects at the interface of the composite roll, and the depth of the radial and axial fusion layers is uniform and uniform, and the quality of the composite interface is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com