A system and method for exhaust water vapor deposition in rail vehicle

A rail vehicle and drainage system technology, applied in the field of rail vehicles, can solve the problems of reducing the thermal insulation capacity of vehicle insulation materials, corrosion of equipment and materials, train riding comfort and the impact of the entire life cycle, to prevent corrosion and ensure heat insulation performance , to avoid the effect of stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below by taking a double-deck rail vehicle as an example, but the protection scope of the present invention is not limited thereby.

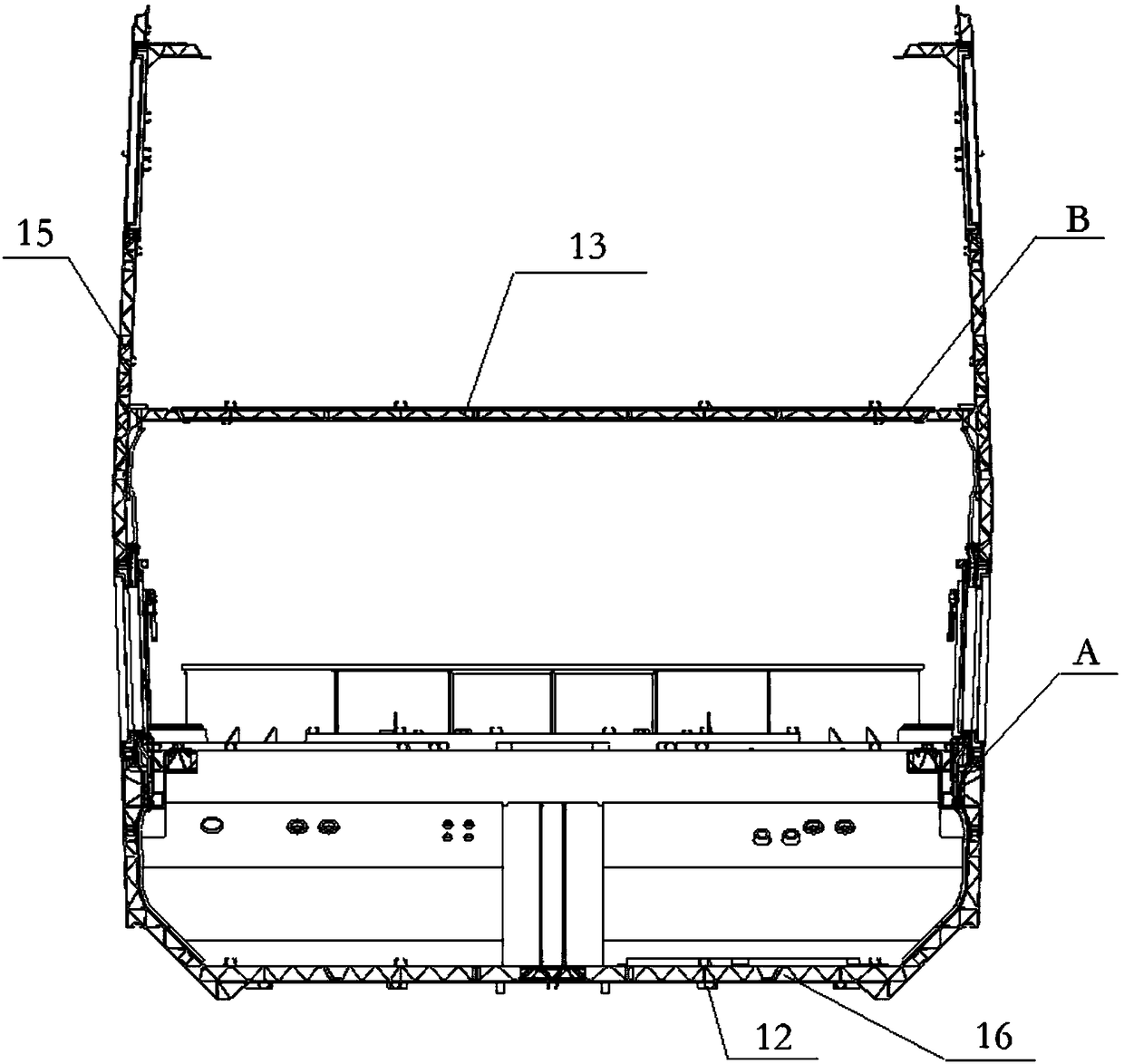

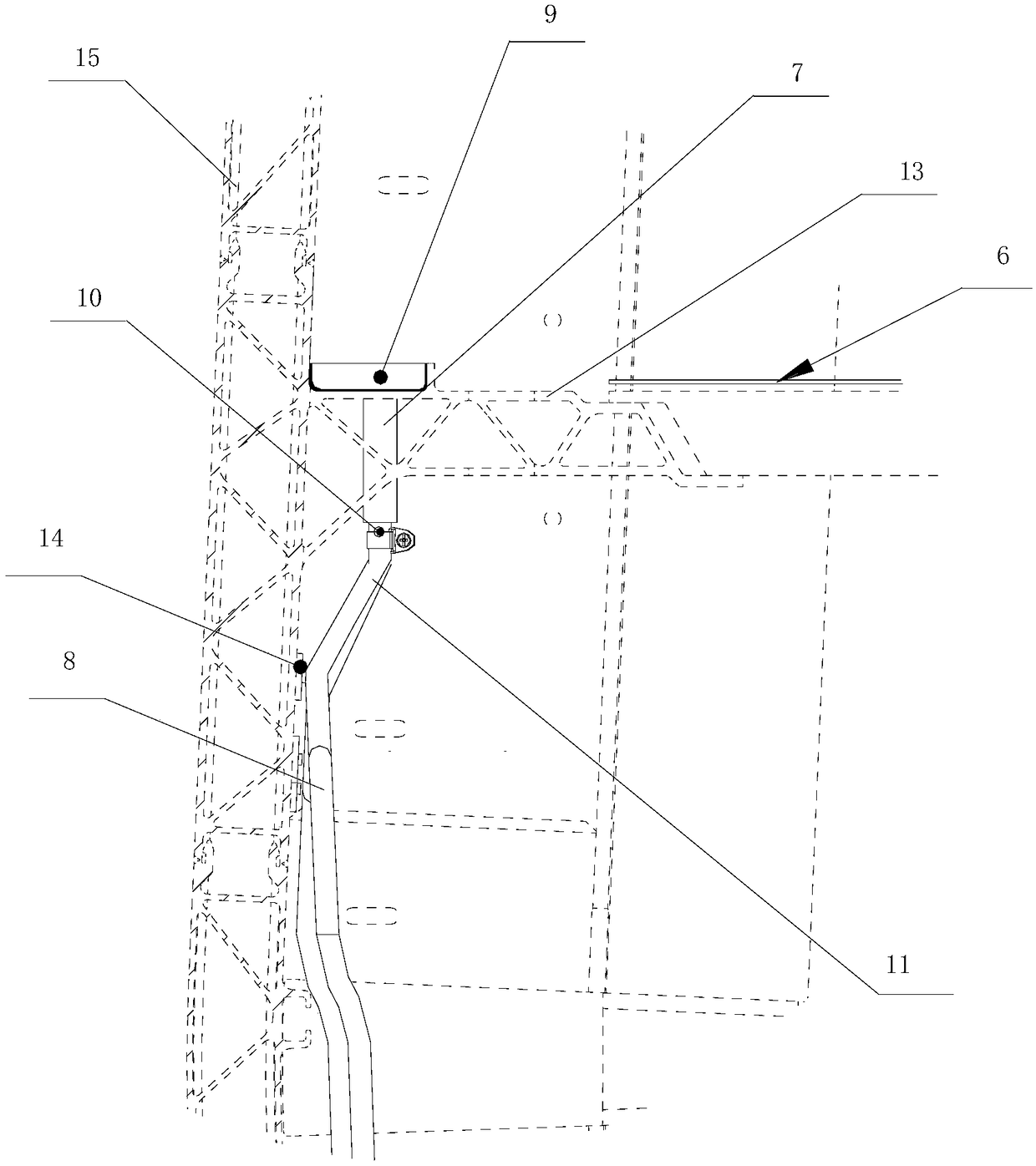

[0022] Such as figure 1 As shown, the water vapor accumulation and drainage system in the rail vehicle of the present invention is composed of two parts, the window accumulation drainage system A and the vehicle volume drainage system B.

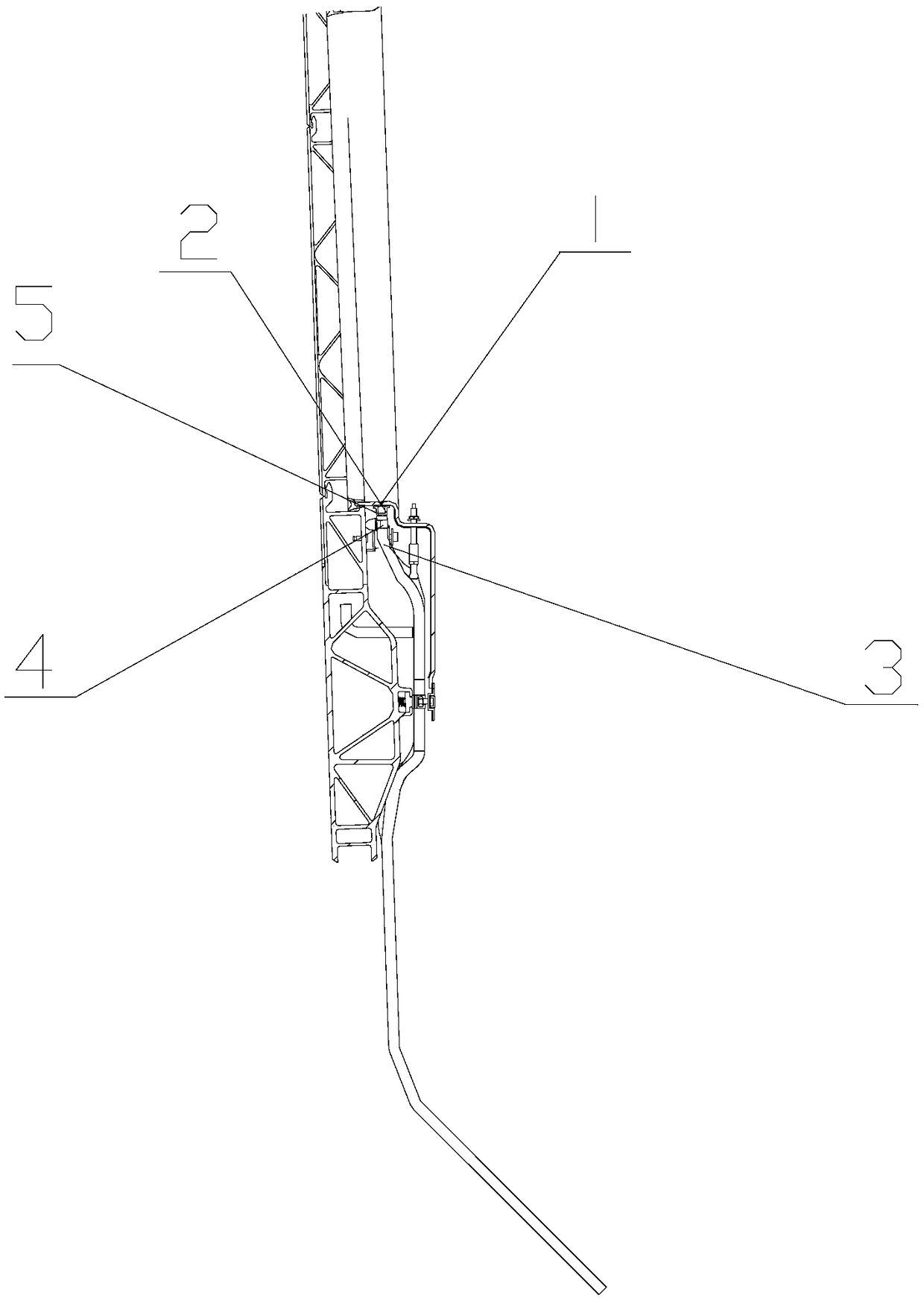

[0023] Such as figure 2 As shown, the vehicle window drainage system is mainly composed of a window sill hidden groove 1, a window sill water storage tank 2, a window drain pipe 3, a window drain pipe joint 4, and a sealant 5; the window sill hidden groove 1 is arranged on the window sill, and the window sill hidden groove 1 is provided with a window sill water storage tank 2, and the bottom of the window sill water storage tank 2 is provided with a window drain pipe joint 4, and the window drain pipe 3 is connected with the vehicle window drain pipe joi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap